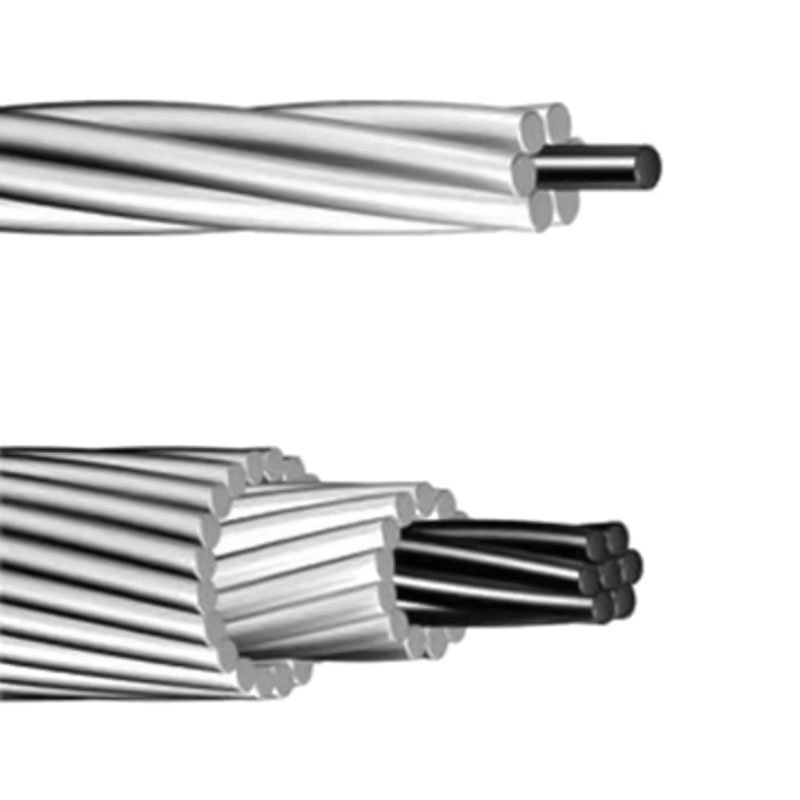

Durable ACSR Conductors for Overhead Lines

ACSR conductors (Aluminum Conductor Steel Reinforced) are the most common type of overhead conductor used for power transmission and distribution. They are made of a steel core surrounded by a layer of aluminum wires. The steel core provides strength, while the aluminum wires provide conductivity.

- High tensile strength for long-span installations.

- Excellent conductivity with a superior conductivity-to-weight ratio.

- Durable construction with concentric stranding.

- Corrosion resistance from galvanized or aluminized steel core.

- Manufactured to international standards like ASTM B232.

Description

The ACSR Conductors (Aluminum Conductor Steel Reinforced) from EPCOM represent the industry standard for high-performance overhead power transmission and distribution lines. Engineered for superior strength and conductivity, this conductor is the backbone of reliable national and regional power grids. Consequently, its robust design ensures optimal performance even across the most demanding long-span installations, such as river crossings and rugged terrain. EPCOM’s commitment to quality manufacturing guarantees a product that delivers both exceptional electrical characteristics and long-term mechanical durability.

Core Features of EPCOM’s ACSR Conductors

Our ACSR Conductor is designed with a composite structure that leverages the distinct advantages of both aluminum and steel. This intelligent engineering results in a conductor that offers a perfect balance of strength, conductivity, and cost-effectiveness for large-scale power projects.

- High Tensile Strength: The steel core provides exceptional mechanical strength, allowing for longer spans between transmission towers. This reduces the number of towers required, leading to significant cost savings in materials and construction.

- Excellent Conductivity: High-purity 1350-H19 aluminum strands form the outer conductive layers. Aluminum offers a superior conductivity-to-weight ratio compared to copper, making the conductor lighter and easier to install without sacrificing performance.

- Durable Construction: The conductor features concentric stranding, where layers of aluminum wires are helically wrapped around the solid or stranded steel core. This design enhances flexibility and reduces mechanical stress during installation and operation.

- Corrosion Resistance: The steel core is available with Class A, B, or C galvanization (zinc coating) or an aluminum coating (aluminized) for enhanced protection against atmospheric corrosion, extending the service life of the conductor.

Technical Specifications for the ACSR Conductors

EPCOM manufactures ACSR Conductors in strict accordance with leading international standards to ensure interoperability and safety. Below is a detailed specification chart for some of our most common conductor configurations. Custom designs are also available to meet specific project requirements.

| Code Name | Stranding (Al/St) | Area (mm²) | Overall Diameter (mm) | Rated Tensile Strength (kN) | Approx. Weight (kg/km) |

|---|---|---|---|---|---|

| Dog | 6/4.72 | 7/1.57 | 105 | 14.15 | 42.25 | 484 |

| Wolf | 30/2.59 | 7/2.59 | 158.8 | 18.13 | 60.84 | 696 |

| Panther | 30/3.00 | 7/3.00 | 212.1 | 21.00 | 82.69 | 948 |

| Zebra | 54/3.18 | 7/3.18 | 428.9 | 28.62 | 131.9 | 1621 |

Standards and Compliance

Quality and safety are non-negotiable in power transmission. Therefore, EPCOM’s ACSR Conductor is manufactured and tested to meet or exceed major international standards, including the ASTM B232 specification for Concentric-Lay-Stranded Aluminum Conductors, Coated-Steel Reinforced. We also adhere to other globally recognized standards such as BS 215, IEC 61089, and DIN 48204 upon request.

Applications and Recommended Accessories for ACSR Conductors

The unique properties of the ACSR Conductor make it the ideal choice for a wide range of overhead applications. Its high strength-to-weight ratio is particularly advantageous for:

- Primary and secondary overhead distribution lines.

- High-voltage and extra-high-voltage (EHV) transmission lines.

- Long-span projects, including river, valley, or lake crossings.

- Installations in areas with high wind or ice loading conditions.

A successful and long-lasting installation depends not only on the quality of the conductor but also on the hardware used to support and connect it. EPCOM supplies a complete range of accessories designed to work seamlessly with our ACSR conductors.

Essential Installation Hardware

For optimal performance and safety, we recommend using EPCOM-approved hardware. Using high-quality fittings prevents conductor damage and ensures reliable electrical and mechanical connections.

- Suspension and Support: To safely suspend the conductor from transmission towers, the XGU Suspension Clamp is essential. It provides a secure pivot point that minimizes stress on the conductor at the support point.

- Conductor Protection: At suspension and termination points, the conductor is exposed to high compressive forces and vibration. Applying Preformed Armor Rods over the conductor provides a protective layer, distributing stress and preventing abrasion and fatigue.

- Joining and Tapping: For creating reliable, non-tension electrical connections between two conductors, the Jbtl Parallel Groove Connector is the ideal solution. Its design ensures a solid, low-resistance tap-off or splice point.

Choose EPCOM for Unmatched Reliability

At EPCOM, we are dedicated to powering progress by providing superior products for electrical infrastructure. Our manufacturing processes are rigorously controlled to ensure that every meter of our ACSR Conductor meets the highest standards of quality and performance. By choosing EPCOM, you are investing in a product engineered for decades of reliable service. Contact our technical sales team today to discuss your project requirements and discover how our solutions can enhance your power transmission system.