High-Performance XHHW Wire for Industrial Use

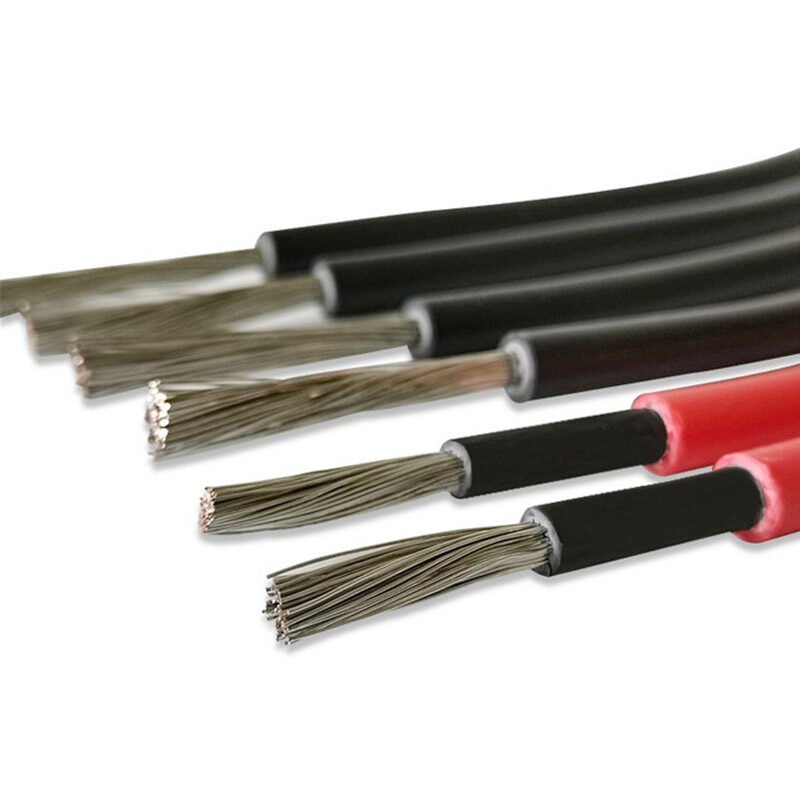

XHHW Wire is a type of electrical wire that is commonly used for building wiring and electrical installations. It is a single-conductor, cross-linked polyethylene (XLPE) insulated wire that is rated for 600 volts and 90°C in dry locations and 75°C in wet locations. XHHW wire is also resistant to water, oil, and chemicals, making it a versatile and durable option for a variety of applications.

- High-Performance XHHW-2 Wire

- Stranded aluminum alloy or copper conductor

- Cross-linked Polyethylene (XLPE) insulation

- Rated 90°C in wet and dry locations

- Resistant to moisture, chemicals, and abrasion

Description

XHHW wire from EPCOM is an essential component for modern electrical systems, offering superior performance in demanding environments. This type of wire, whose name stands for “Cross-linked Polyethylene High Heat-resistant Water-resistant,” is engineered for exceptional durability and safety. It serves as a reliable solution for power distribution in commercial, industrial, and institutional buildings. At EPCOM, we provide high-quality XHHW conductors that meet rigorous industry standards, ensuring longevity and optimal electrical performance for all applications. The cross-linked polyethylene (XLPE) insulation provides a distinct advantage over other insulation types like thermoplastic, particularly in its thermal stability and resistance to moisture and abrasion.

The versatility of XHHW electrical wire makes it suitable for installation in a variety of settings. It can be installed in conduits, ducts, and other approved raceways for services, feeders, and branch-circuit wiring. Its robust construction ensures it can withstand the physical stresses of pulling and installation while maintaining its electrical integrity. Whether you are wiring a new manufacturing facility or upgrading a commercial complex’s power grid, EPCOM’s wire provides the safety and efficiency required for the job. Our commitment is to deliver products that not only meet but exceed expectations for electrical contractors and engineers.

Understanding the Construction of XHHW Wire

The performance of any wire is determined by its construction. EPCOM’s XHHW wire is manufactured with precision to ensure it performs reliably under various operational stresses. The core components work together to provide a cable that is not only robust but also highly efficient in power transmission.

Conductor and Insulation of our XHHW Wire

At the heart of our XHHW wire is a stranded aluminum alloy conductor (such as 8000 series) or a copper conductor. This stranded design provides greater flexibility compared to solid conductors, simplifying installation in complex conduit runs. Surrounding the conductor is the key component: the thermoset cross-linked polyethylene (XLPE) insulation. This advanced insulation material offers several key benefits:

- High Heat Resistance: It is rated for operation at temperatures up to 90°C (194°F) in both wet and dry locations, conforming to the “-2” designation.

- Moisture Resistance: The “W” in its name signifies its excellent performance in wet environments, preventing moisture ingress that could lead to electrical failures.

- Chemical and Abrasion Resistance: XLPE insulation is tough, protecting the conductor from physical damage during installation and from exposure to chemicals and oils over its service life.

- Low Dielectric Constant: It is an ideal choice for environments where a low dielectric constant (typically below 3.5) is critical, ensuring signal integrity.

Primary Applications of XHHW Electrical Wire

Due to its robust characteristics, XHHW wire is specified for a wide range of applications across multiple industries. Its ability to perform in high-heat and high-moisture environments makes it a go-to choice for projects where reliability is non-negotiable.

Commercial and Industrial Installations

In commercial and industrial settings, XHHW wire is commonly used for feeders and branch circuits. It distributes power from the main switchgear to lighting, HVAC systems, machinery, and other electrical loads. Its durability ensures a long service life, reducing the need for costly maintenance and replacement. Furthermore, its compliance with the National Electrical Code (NEC) makes it a trusted product for public and private infrastructure projects.

Use in Wet and Dry Locations

The “W-2” rating is critical. It certifies the wire for use in both dry and wet locations at a continuous conductor temperature of 90°C. This makes it suitable for installation in underground conduits that may be exposed to water, as well as in outdoor raceways or indoor industrial environments with high humidity. This versatility simplifies material selection and inventory for electrical contractors.

XHHW Wire Product Specifications

EPCOM provides a comprehensive range of XHHW wires to meet diverse project requirements. The following table outlines the typical specifications for our products. Please note that custom sizes and configurations may be available upon request.

| Attribute | Specification |

|---|---|

| Conductor | Compressed stranded 8000 series aluminum alloy or soft annealed copper |

| Insulation | Cross-linked Polyethylene (XLPE) |

| Voltage Rating | 600 Volts |

| Temperature Rating | 90°C in Wet and Dry Locations |

| Applicable Standards | UL Standard 44, Federal Specification A-A-59544, RoHS Compliant |

| Conductor Sizes (AWG) | 8 AWG through 1000 kcmil |

| Insulation Colors | Black, Red, White, Green, Blue (other colors available) |

| Sunlight Resistance | Yes (all colors) |

Essential Tools and Accessories for Installation

A successful and safe electrical installation depends on both high-quality wire and the right tools and accessories. EPCOM supports your projects by providing a full range of compatible products designed to work seamlessly with our XHHW wire.

Connectors, Tools, and Protection

Properly terminating and connecting conductors is critical for a secure and lasting electrical system. For reliable connections between aluminum or copper conductors, our JBT Parallel Groove Connector provides excellent mechanical strength and electrical conductivity. When making these connections, it is vital to use professional-grade tools. The YQK Cable Crimping Pliers from EPCOM ensure a solid and dependable crimp every time, which is essential for maintaining system integrity. Finally, all connections must be housed safely. An Electrical Junction Box protects splices and terminations from environmental factors and physical damage, ensuring the safety and longevity of the entire installation.

Choose EPCOM for Your XHHW Wire Needs

At EPCOM, we are dedicated to providing superior electrical products that form the backbone of safe and efficient power systems. Our XHHW wire is manufactured to the highest quality and safety standards, offering an unbeatable combination of durability, performance, and value. With its excellent thermal properties, resistance to environmental factors, and flexible design, it is the ideal choice for a wide array of industrial and commercial applications. By choosing EPCOM, you are partnering with a supplier that understands the technical demands of your industry and is committed to your project’s success. Contact us today to discuss your specific requirements and learn how our products can benefit your next installation.