Anchoring Clamp: Guide to Secure Pole Line Hardware

An Anchoring Clamp is a critical component in the world of aerial cable installation, serving as the backbone for securing conductors in both telecommunication and electrical networks. At EPCOM, we understand that the reliability of your entire overhead infrastructure often comes down to the quality of these essential devices. Therefore, this comprehensive guide will explore every facet of the anchoring clamp, from its fundamental purpose and diverse types to selection criteria and installation best practices. Moreover, we will delve into how these clamps integrate with other vital pole line hardware to create a robust and lasting network. Whether you are working with fiber optic cables or electrical conductors, understanding the nuances of a high-quality anchoring clamp is paramount for operational success and safety.

The Fundamental Role of an Anchoring Clamp in Networks

In any overhead cable deployment, managing tension is a primary concern. Cables are subjected to various forces, including their own weight, wind, ice, and thermal expansion or contraction. An anchoring clamp, also known as a dead-end clamp or tension clamp, is specifically engineered to terminate an aerial cable and transfer these mechanical stresses safely to a support structure, such as a pole or building facade. Without a reliable anchoring clamp, cables would sag, suffer from excessive tension leading to damage, and ultimately cause network failure. Consequently, their role is not merely supportive but foundational to network longevity and integrity.

The primary function is to grip the cable securely without causing damage to the sensitive internal components, like optical fibers or electrical conductors. This is achieved through various designs, most notably wedge-style mechanisms, which increase gripping force as tension on the cable increases. This self-adjusting feature ensures a firm hold under all environmental conditions. Furthermore, these clamps are designed for easy and rapid installation, which significantly reduces labor time and costs for network operators. Ultimately, the humble anchoring clamp is a linchpin of modern infrastructure, ensuring that communication and power lines remain secure and operational for years to come. This makes choosing a high-quality supplier like EPCOM a crucial business decision.

Exploring the Diverse Types of Anchoring Clamps

The term “anchoring clamp” covers a wide range of devices, each tailored for specific cable types, tension loads, and applications. Understanding these variations is the first step in selecting the correct hardware for your project. The materials, design, and mechanism of an anchoring clamp dictate its suitability for a given task. At EPCOM, we provide a specialized portfolio to meet the rigorous demands of global network deployments.

Wedge-Type Anchoring Clamp: The Industry Standard

The wedge-type anchoring clamp is arguably the most common design for FTTH (Fiber-to-the-Home) and other telecommunication drop cables. Its design is both simple and ingenious. The clamp consists of a conical body, a pair of self-adjusting plastic wedges, and a flexible bail. When the cable is placed between the wedges and tension is applied, the wedges are pulled into the conical body, tightening their grip on the cable sheath. This provides a secure anchor that is proportional to the cable’s tension.

Key advantages include:

- Tool-Free Installation: Most wedge clamps can be installed by hand, dramatically speeding up deployment.

- Self-Adjusting Grip: The design naturally compensates for load variations, ensuring a reliable hold.

- Non-Damaging: The plastic wedges grip the cable sheath firmly but are designed to not damage the internal fibers or conductors.

- Corrosion Resistance: Typically made from UV-resistant thermoplastic and stainless steel or galvanized steel bails, they are built to withstand harsh weather conditions for decades.

Strain Clamps for High-Tension Applications

When dealing with heavier conductors, such as those in electrical distribution lines or large-diameter fiber optic cables, a more robust solution is required. Strain clamps, another form of anchoring clamp, are designed for these high-tension scenarios. They often feature bolted mechanisms or helical designs that distribute the clamping force over a larger surface area of the cable. This prevents damage to the conductor while providing the immense holding strength needed to maintain proper sag and tension over long spans. These are essential for grid reliability and are a core part of utility-grade pole line hardware.

Plastic vs. Metal: Choosing the Right Anchoring Clamp Material

The choice between a plastic (thermoplastic) and a metallic anchoring clamp depends entirely on the application. For final-drop FTTH connections, where cables are small and tensions are relatively low, UV-stabilized, glass-fiber-reinforced plastic clamps are ideal. They are lightweight, corrosion-proof, and cost-effective. However, for main-line electrical conductors or heavy-duty guying applications, nothing beats the sheer strength and durability of metals like galvanized steel or aluminum alloy. EPCOM ensures that all materials used in our clamps, whether plastic or metal, meet stringent quality standards for longevity and performance, as detailed in various international engineering standards.

Critical Applications of a High-Performance Anchoring Clamp

Anchoring clamps are not a one-size-fits-all product. Their design is intimately linked to their intended application, which spans across the telecommunications and energy sectors. Using the right clamp for the job is non-negotiable for safety and reliability.

Securing ADSS Cables in FTTx Networks

One of the most important applications for modern anchoring clamps is in the deployment of All-Dielectric Self-Supporting (ADSS) cables. These fiber optic cables are the lifeblood of modern broadband networks. An anchoring clamp designed for ADSS must securely grip the cable’s outer polyethylene jacket without causing attenuation or damage to the delicate optical fibers within. This is why EPCOM’s clamps are meticulously engineered and tested. They provide the necessary tensile hold for dead-ending ADSS on poles and towers, which is a crucial step in building out a fiber network. In conjunction with our clamps, the integrity of the entire fiber line, such as our high-quality ADSS cable, is maintained from the distribution point to the subscriber.

Anchoring in Overhead Electrical Distribution

In the realm of electrical power, anchoring clamps (often called dead-end strain clamps) play a vital safety role. They are used to terminate conductors on transmission and distribution poles. The forces involved are significantly higher than in telecom, and the consequences of failure are severe. These clamps must handle immense mechanical loads and provide excellent electrical compatibility with the conductor material (e.g., ACSR, AAAC). They are designed to ensure the electrical line remains securely tensioned and attached to the pole insulator assembly, guaranteeing the uninterrupted flow of power to communities and industries. Reliability here is not just about performance; it’s about public safety.

Support in Telecommunication and CATV Infrastructure

Beyond fiber optics, traditional telecommunication networks using copper cables, as well as Cable TV (CATV) networks using coaxial cables, rely heavily on anchoring clamps. Drop wire clamps, for instance, are a common sight, securing the service line from the utility pole to a subscriber’s home. These clamps must be durable enough to withstand decades of sun, rain, and wind while being simple enough for a field technician to install quickly. EPCOM provides a range of anchoring solutions tailored for these specific cable types, ensuring a dependable connection for every user.

The EPCOM Advantage: Why Our Anchoring Clamps Lead

In a market filled with options, EPCOM distinguishes itself through an unwavering commitment to quality, innovation, and customer-centric design. Our pole line hardware is not just a commodity; it’s a promise of reliability.

Superior Materials and Advanced Manufacturing

The longevity of an anchoring clamp begins with its raw materials. We use only premium-grade, UV-stabilized, fiber-reinforced polymers for our plastic clamps, ensuring they won’t become brittle or fail under prolonged sun exposure. Our metallic components, from stainless steel bails to galvanized steel bodies, are selected for maximum corrosion resistance and mechanical strength. This commitment to materials, combined with state-of-the-art injection molding and metal forming processes, results in a product with exceptional consistency and durability. We build our hardware to last, reducing the total cost of ownership for our clients through fewer replacements and less maintenance.

Rigorous Quality Control and Performance Testing

Every anchoring clamp model produced by EPCOM undergoes a battery of rigorous tests before it is approved for sale. These tests simulate real-world conditions and beyond, ensuring our products meet and exceed industry specifications. Key tests include:

- Tensile Load Testing: We pull the clamps to their breaking point to verify their maximum rated load, ensuring a robust safety margin.

- Climatic Chamber Testing: Clamps are subjected to cycles of extreme heat, cold, humidity, and UV radiation to test their long-term environmental stability.

- Vibration Testing: To simulate the effects of wind-induced aeolian vibration, clamps are tested to ensure their grip remains secure over time.

- Salt Spray Testing: For our metallic components, this test accelerates corrosion to verify the quality of our galvanization and stainless steel grades.

This exhaustive testing protocol guarantees that when you install an EPCOM anchoring clamp, you are installing a piece of hardware you can trust unconditionally.

How to Select the Right Anchoring Clamp for Your Project

Choosing the correct anchoring clamp is a technical decision that directly impacts network performance and safety. Several key factors must be considered to make an informed choice.

1. Cable Compatibility and Diameter

The most crucial factor is the cable itself. The anchoring clamp must be designed for the specific type (e.g., ADSS, drop wire, electrical conductor) and diameter range of the cable you are using. Using a clamp that is too large will result in insufficient grip, while a clamp that is too small can damage the cable. Always check the manufacturer’s specifications to ensure the clamp’s accepted diameter range matches your cable’s outer diameter.

2. Minimum Breaking Load (MBL) and Tension Requirements

You must understand the mechanical tension the clamp will need to endure. This is calculated based on span length, cable weight, and maximum environmental loading (ice and wind). The anchoring clamp’s Minimum Breaking Load (MBL) must be significantly higher than the expected maximum working tension. A proper safety factor (e.g., 2:1 or higher) is essential to account for unforeseen events and long-term material fatigue. EPCOM clearly states the MBL for all its tension-bearing products.

3. Environmental Factors and Material Choice

Consider the installation environment. Will the clamp be exposed to extreme sunlight, saltwater spray, or industrial pollutants? For coastal or highly corrosive environments, stainless steel components are superior to galvanized steel. For areas with very high UV indexes, ensuring the clamp’s plastic components are made from high-grade, UV-stabilized polymer is critical. The operational lifespan of your network depends on making the right material choices upfront.

4. Installation Method and Tools

Consider the practicalities of installation. For mass deployments like FTTH drops, tool-free wedge clamps are highly efficient. For high-tension electrical lines, bolted clamps that require specific torque wrenches are necessary to ensure proper application of force. Choosing a clamp that aligns with your workforce’s training and available tools can streamline the deployment process and reduce the risk of installation errors.

EPCOM Anchoring Clamp Feature Comparison

To assist in your selection process, the table below highlights key features of different anchoring clamp types offered by EPCOM. This allows for a quick comparison based on common project requirements.

| Feature | Wedge-Type Anchoring Clamp (PA-Series) | Bolted Strain Clamp (NLL-Series) |

|---|---|---|

| Primary Application | FTTH Drop Cables, Low-Voltage ABC | Mainline Electrical Conductors, Guy Wires |

| Cable Diameter Range | 2mm – 12mm (Varies by model) | 10mm – 35mm+ (Varies by model) |

| Typical MBL | 1.5 kN – 5 kN | 20 kN – 90 kN |

| Body Material | UV-Resistant, Fiber-Reinforced Polymer | High-Strength Aluminum Alloy |

| Bail/Hardware Material | Stainless Steel or Hot-Dip Galvanized Steel | Hot-Dip Galvanized Steel |

| Installation | Tool-free | Requires wrench/torque tool |

The Supporting Cast: Why an Anchoring Clamp Needs Other Hardware

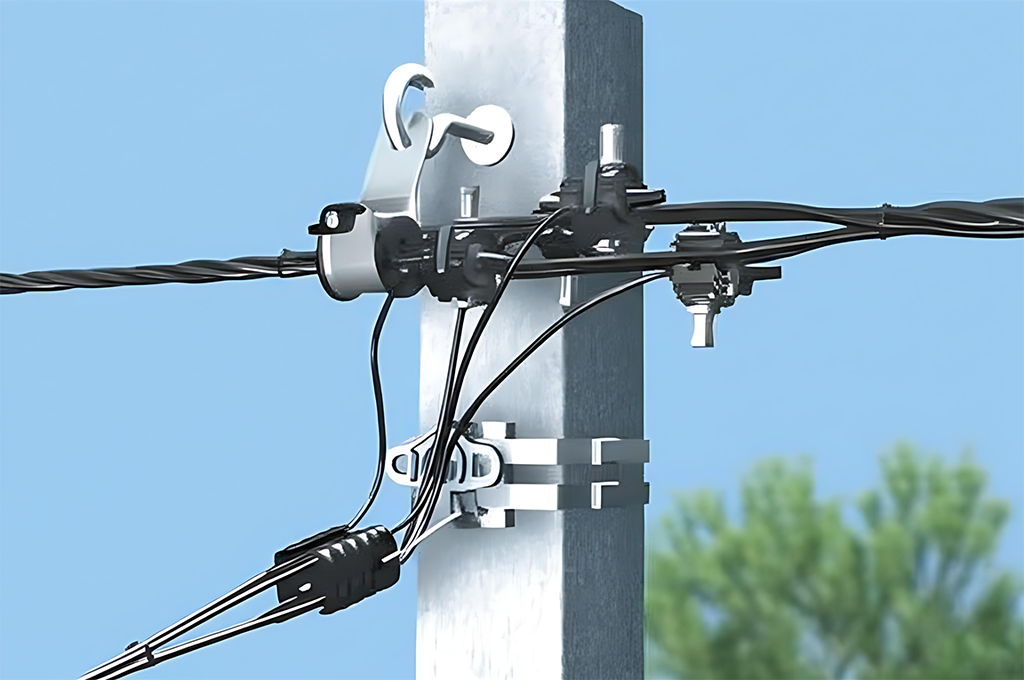

An anchoring clamp, while crucial, does not work in isolation. It is part of a complete system of pole line hardware that ensures a secure and functional aerial cable route. Understanding how these components interact is key to designing a truly resilient network. Two of the most important companion products are suspension clamps and stainless steel strapping.

The Synergy with Preformed Suspension Clamps

While an anchoring clamp is used to terminate a cable at the end of a span or at a significant angle, a suspension clamp is used to support the cable along straight sections of the route. The job of the suspension clamp is to hold the cable to the pole without gripping it so tightly that it can’t move slightly. This is important for allowing the cable to equalize tension along the line, especially due to thermal expansion and contraction. At EPCOM, we offer a full range of suspension hardware, like the preformed suspension clamp, which provides excellent support and protection for the cable. A typical line will use anchoring clamps at the ends of the run and suspension clamps on all the intermediate poles, working together to manage the cable’s mechanical load perfectly.

The Unyielding Grip of Stainless Steel Strapping

How do you attach all this hardware to the pole? In many modern installations, the answer is stainless steel banding. This versatile strapping system allows technicians to mount brackets, clamps, and other hardware securely to utility poles of any diameter without the need for drilling. High-quality stainless steel strap from EPCOM provides immense tensile strength and superior corrosion resistance, making it a “fit and forget” solution. It is used to secure the mounting brackets that will, in turn, hold the anchoring or suspension clamps. Using a robust strapping system is just as important as the clamps themselves, as it forms the ultimate connection to the support structure.

Installation Best Practices for Your Anchoring Clamp

Proper installation is just as critical as product selection. A high-quality anchoring clamp can fail if it’s not installed correctly. Adhering to best practices ensures maximum performance and safety.

- Inspect the Clamp and Cable: Before installation, visually inspect the anchoring clamp for any signs of damage from shipping or handling. Also, inspect the section of the cable where the clamp will be applied, ensuring it is clean and free from any cuts or deformities in the sheath.

- Respect the Cable’s Bend Radius: When routing the cable to the clamp, never bend it sharper than its specified minimum bend radius. Forcing a tight bend can damage optical fibers or deform coaxial cables, leading to signal degradation.

- Open the Bail and Prepare the Wedges: For a wedge-type clamp, open the bail wire. Ensure the wedges are loose and ready to accept the cable. Do not use any lubricants unless explicitly specified by the manufacturer, as this can impair gripping performance.

- Insert the Cable Correctly: Place the cable into the clamp’s channel between the wedges. Pay attention to any directional arrows on the clamp. Ensure the cable is seated properly and extends a short distance past the end of the clamp body.

- Apply Initial Tension and Seat the Wedges: Pull the cable by hand to apply initial tension. You should see the wedges begin to engage and move into the clamp body. This initial seating is crucial for the self-tensioning mechanism to work correctly.

- Attach to the Support Bracket: With the clamp now loosely holding the cable, hook the bail onto the pole bracket, pigtail hook, or other support hardware. Ensure the connection is secure.

- Tension the Cable to Final Sag: Proceed with tensioning the cable span to the correct sag level as per your engineering specifications. As the tension increases, the wedges in the anchoring clamp will tighten their grip, locking the cable securely in place.

- Final Inspection: Once at final tension, perform a final visual check of the clamp, the bail connection, and the cable to ensure everything is seated correctly and under no undue stress.

Frequently Asked Questions (FAQ) about the Anchoring Clamp

Here are answers to some of the most common questions we receive at EPCOM about anchoring clamps. This section aims to provide quick, clear information to help you in your planning and deployment.

What is the difference between an anchoring clamp and a suspension clamp?

An anchoring clamp (or dead-end clamp) is designed to terminate a cable and hold its full mechanical tension. It is used at the start and end of a cable run, and at any point where the line direction changes significantly. A suspension clamp, on the other hand, is designed to simply support the weight of the cable on in-line, tangent poles. It allows the cable to move slightly, which helps to balance tension along the entire line.

Can I reuse an anchoring clamp?

Generally, it is not recommended to reuse wedge-type anchoring clamps. The process of tensioning and then releasing a clamp can cause slight deformation in the plastic wedges, which might compromise its gripping ability on a second installation. Given their low cost relative to the cost of a network failure, it is always best practice to use a new clamp for every installation. For heavy-duty bolted strain clamps, reuse may be possible if they are thoroughly inspected for wear and fatigue, but replacement is still the safest policy.

How do I know what size anchoring clamp to use?

You must refer to two specifications: the outer diameter of your cable and the maximum tension it will be under. The anchoring clamp you choose must list your cable’s diameter within its acceptable range and have a Minimum Breaking Load (MBL) that is well above your calculated maximum line tension (including a safety factor).

Does weather affect the performance of an anchoring clamp?

Yes, and they are designed to handle it. High-quality anchoring clamps from EPCOM are made from materials that can withstand a wide range of temperatures, from arctic cold to desert heat. The UV-stabilized materials prevent sunlight from making the plastic brittle. The self-adjusting nature of the wedge mechanism helps to maintain a secure grip as the cable expands and contracts with temperature changes. Furthermore, the use of corrosion-resistant materials like stainless and galvanized steel ensures performance in wet or salty conditions. For more information about how materials react in different environments, resources from organizations like the National Association of Corrosion Engineers (NACE) can be very insightful.

Why is my anchoring clamp slipping?

Clamp slippage is almost always due to one of three reasons: 1) The clamp is the wrong size for the cable. 2) The cable sheath was contaminated with oil, grease, or an unapproved lubricant. 3) The clamp is a low-quality product that is not properly designed or manufactured. Always ensure you are using the correct size clamp from a reputable manufacturer like EPCOM on a clean cable to prevent this issue.

Your Trusted Partner for Anchoring Clamps and Pole Line Hardware

The anchoring clamp is a small but mighty hero in the world of aerial networks. Its ability to reliably manage immense mechanical forces is fundamental to keeping our world connected and powered. From the efficiency of a tool-free wedge clamp in an FTTx drop to the brute strength of a bolted strain clamp on a transmission line, choosing the right hardware is a decision of paramount importance.

At EPCOM, we have built our reputation on providing pole line hardware that network operators can trust without question. Our rigorous design process, premium material selection, and exhaustive testing protocols ensure that every anchoring clamp we sell delivers uncompromising performance and longevity. We encourage you to explore our product range and leverage our expertise for your next project. By partnering with EPCOM, you are not just buying a component; you are investing in the long-term reliability and integrity of your network.

Contact us today to discuss your specific anchoring clamp requirements and discover how EPCOM can provide the secure foundation your infrastructure deserves.