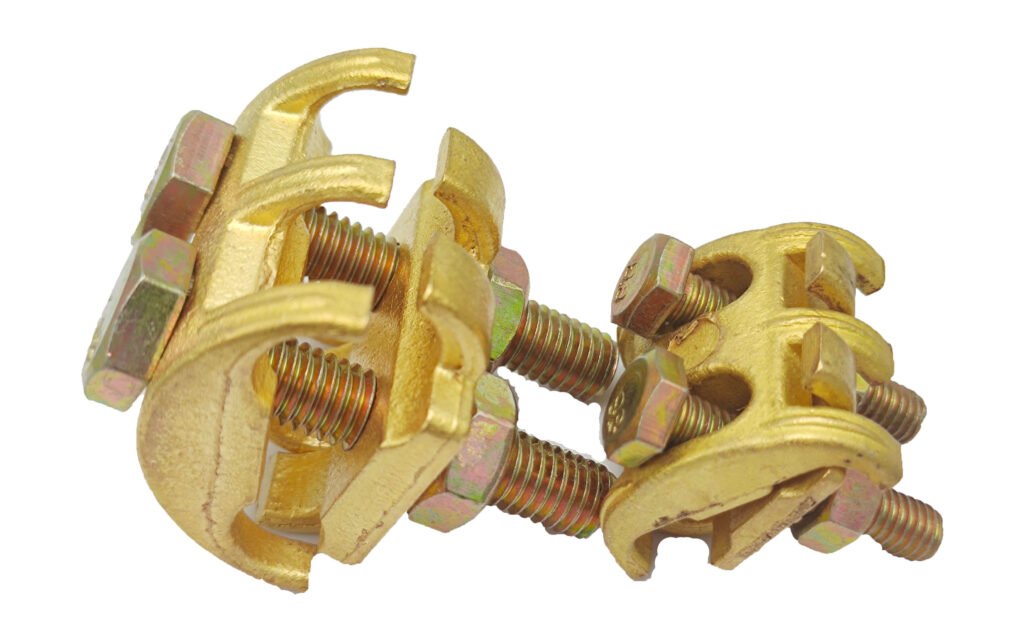

Brass Parallel Groove Connector: Power Solutions

Brass Parallel Groove Connector technology stands as the backbone of modern electrical distribution, ensuring stability where it matters most. In the intricate web of overhead power lines, the integrity of every connection point dictates the reliability of the entire grid. Engineers and utility providers constantly seek components that offer not just conductivity, but longevity against harsh environmental factors. Whether you are managing a municipal grid or a private industrial network, understanding the mechanics of these connectors is vital.

Electricity demands respect. It also demands precision. The transition from copper to aluminum conductors, or simply joining two copper lines, presents unique metallurgical challenges. This is where the specific engineering of groove connectors becomes essential. They are not merely fasteners; they are conductive bridges designed to withstand thermal cycling and mechanical stress over decades. At EPCOM, we recognize that quality cannot be compromised when safety is on the line.

This comprehensive resource explores the technical superiority, installation nuances, and strategic advantages of using high-grade brass connectors. We will delve deep into material science, compare alternatives, and outline why choosing the right fitting saves costs in the long run.

The Evolution of the Brass Parallel Groove Connector

Historically, connecting overhead conductors was a crude process. Early methods often resulted in high resistance joints. These poor connections led to overheating and eventual line failure. The introduction of the Brass Parallel Groove Connector revolutionized this specific aspect of electrical engineering. By utilizing the unique properties of brass—an alloy primarily of copper and zinc—engineers achieved a balance of strength and conductivity.

Brass offers excellent resistance to corrosion. This is particularly crucial in coastal or industrial areas where airborne salts and chemicals can rapidly degrade softer metals. Furthermore, the “parallel groove” design ensures a large contact surface area. A larger surface area equates to lower electrical resistance. Lower resistance means less heat generation and higher efficiency for the utility provider.

Modern iterations of these connectors have evolved further. They now incorporate specific groove profiles that bite through oxide layers on conductors. This ensures a metal-to-metal contact that remains stable even as the wire expands and contracts with daily temperature shifts. This evolution marks a significant leap from the simple twisted wire connections of the past.

Why a Brass Parallel Groove Connector Prevents Failure

Failure in overhead lines is rarely sudden. It is usually a cumulative process. A poor connection creates a “hot spot.” Over time, this heat anneals the wire, making it brittle. Eventually, the line snaps under wind load or ice weight. A high-quality Brass Parallel Groove Connector mitigates this risk entirely.

The mechanical design of the connector maintains constant pressure on the conductor. This is often referred to as “spring action” in engineering terms. Even if the wire creeps or flows cold over time, the clamping force remains sufficient to maintain conductivity. This reliability is why major utility companies specify brass for their critical copper network segments.

Moreover, the galvanic compatibility of brass with copper conductors eliminates the risk of galvanic corrosion. When dissimilar metals touch in the presence of moisture, one will corrode the other. Using brass on copper lines is the chemically correct choice, ensuring the joint lasts as long as the conductor itself.

Complementary Fittings for Overhead Lines

While the groove connector is essential for splicing and tapping, a robust power network relies on a suite of harmonized components. A holistic approach to line construction involves selecting the right anchor, suspension, and piercing elements. EPCOM provides a complete ecosystem of these solutions.

For instance, when establishing a branch line without stripping insulation, the TTD Insulation Piercing Connector is the industry standard. It complements the groove connector by offering a sealed, waterproof option for insulated bundles, ensuring that safety is maintained even during live-line work.

In terms of physical support, the conductor must be suspended carefully to avoid abrasion. The XGU Suspension Clamp is designed to hold the cable gently yet firmly. It reduces static stress at the support point, which helps in prolonging the lifespan of the transmission line, working in tandem with the electrical efficiency of our brass connectors.

Furthermore, managing the mechanical tension of the line is critical. A PA500 Tension Clamp is excellent for lower voltage or communication cables, ensuring they do not sag dangerously. For heavier duty requirements on the dead-end poles, the PA2000 Dead End Anchoring Clamp provides the ultimate holding strength. These mechanical anchors ensure that the electrical connections made by the groove connectors are not subjected to physical strain.

Technical Specifications of the Brass Parallel Groove Connector

Understanding the numbers behind the hardware is essential for procurement and engineering validation. Below is a detailed breakdown of the typical specifications found in high-grade EPCOM connectors. These metrics ensure compliance with international safety standards.

| Feature | Specification Standard | Benefit |

|---|---|---|

| Material Composition | High-strength Brass (CuZn40Pb2) | Superior corrosion resistance and strength. |

| Surface Treatment | Tin-plated or Plain | Prevents oxidation; tin allows Al-Cu transition. |

| Bolt Tensile Strength | 8.8 Grade Hot Dip Galvanized | High torque resistance during installation. |

| Conductivity | > 25% IACS | Ensures minimal voltage drop across the joint. |

| Standards Compliance | IEC 61238-1 | Global certification for electrical safety. |

These specifications highlight why generic connectors often fail. They lack the precise alloy composition required to resist stress corrosion cracking. EPCOM ensures every unit meets these rigorous standards before leaving the factory floor.

Installation Guide for Brass Parallel Groove Connector

Even the best hardware can fail if installed incorrectly. The procedure for installing a Brass Parallel Groove Connector is precise. It requires attention to detail to ensure the electrical path is established correctly. This section outlines the best practices endorsed by field engineers globally.

Firstly, conductor preparation is paramount. The wire surface must be thoroughly cleaned. Over time, copper develops a patina, and aluminum develops oxide. These layers are insulators. Using a wire brush to expose bright metal is a non-negotiable step. Once cleaned, a conductive grease is often applied to prevent immediate re-oxidation.

Secondly, the placement of the connector matters. The conductors should sit flush within the grooves. If the wire is misaligned, the pressure plate will not sit flat. This creates a point contact rather than a surface contact. Point contacts lead to high resistance and heat.

Torque Settings for Brass Parallel Groove Connector

The tightening of the bolts is the most critical phase. Under-tightening leads to a loose connection that can arc and spark. Over-tightening can strip the threads or crush the conductor strands, reducing their mechanical strength. Using a calibrated torque wrench is highly recommended.

Manufacturers provide specific torque values, usually measured in Newton-meters (Nm). Adhering to these values ensures the Brass Parallel Groove Connector exerts the “spring” force mentioned earlier. It is also good practice to re-tighten the bolts after a few weeks of service, as the initial settlement of the strands can result in a slight loss of pressure.

Comparative Analysis: Conductivity and Durability

To truly appreciate the value of brass, one must compare it to alternative materials used in the industry, such as galvanized steel or aluminum alloys. While steel is strong, its electrical conductivity is poor. Aluminum is conductive but mechanically softer and prone to “cold flow.”

Brass sits in the optimal middle ground. It possesses the mechanical rigidity to hold a clamp shape under stress, yet retains a significant portion of copper’s conductive properties. This balance is visualized in the chart below, comparing relative suitability for connection interfaces.

Figure 1: Comparative analysis of material performance in harsh utility environments.

As illustrated, while aluminum serves well for standard transmission, the Brass Parallel Groove Connector offers the premium tier of performance, particularly regarding resistance to environmental degradation. This longevity justifies the investment for critical infrastructure.

Environmental Impact and Sustainability

In the modern era, sustainability is a key metric for any project. Utilities are under pressure to reduce their carbon footprint and waste. Brass fittings contribute positively to this goal. Because they are extremely durable, they need replacement far less frequently than inferior alternatives. This reduces the manufacturing demand and the logistics emissions associated with maintenance trips.

Furthermore, brass is highly recyclable. At the end of a line’s lifecycle, the connectors can be melted down and reformed without a significant loss of material properties. This circular economy approach aligns with the environmental goals of major international bodies like the International Electrotechnical Commission (IEC).

EPCOM is committed to sustainable manufacturing practices. By producing long-lasting components, we reduce the aggregate waste in the electrical sector. Choosing a high-quality connector is, therefore, an environmentally responsible decision.

Common Challenges in Overhead Line Connections

Field technicians often report specific issues that plague distribution networks. Understanding these challenges highlights why the Brass Parallel Groove Connector is the preferred solution. One major issue is thermal expansion. Lines heat up during the day and under load, then cool at night. This cycle causes the metal to expand and contract.

Rigid connectors that cannot accommodate this movement eventually loosen. Once loose, air enters the joint, leading to oxidation. The groove design in our brass connectors allows for a certain degree of elasticity. This accommodates the thermal breathing of the conductor without losing electrical contact.

Another challenge is vibration. Wind induces aeolian vibration in power lines. This high-frequency shaking can unscrew bolts over time. The geometry of EPCOM’s connectors, combined with high-grade locking washers or galvanized steel bolts, provides resistance against this vibrational loosening. This is critical for maintaining grid stability during storms.

Safety Standards and Compliance

Safety is non-negotiable. Every Brass Parallel Groove Connector utilized in a public grid must meet stringent safety criteria. The Institute of Electrical and Electronics Engineers (IEEE) sets forth guidelines that dictate how these components must perform under fault conditions.

A short circuit can send massive currents through a line for a split second. The connector must be able to carry this fault current without melting or exploding. EPCOM connectors are tested to withstand these surge currents, ensuring that the connector is never the weak link in the safety chain. This compliance protects not just the grid, but the people living and working below it.

The EPCOM Advantage

The market is flooded with generic fittings. However, consistency is rare. EPCOM distinguishes itself through rigorous quality control. We do not just sell a Brass Parallel Groove Connector; we provide a certified assurance of quality. Our manufacturing process involves spectral analysis of the raw brass alloy to ensure the zinc and copper ratios are exact.

We also focus on the user experience. Our connectors are designed to be installer-friendly. Features like captive bolts prevent parts from falling to the ground during installation atop a pole. Smooth chamfered edges prevent damage to the conductor insulation or the lineman’s gloves. These subtle design choices reflect our deep understanding of the field environment.

Our logistics and support network ensures that whether you need a single batch for a repair or thousands for a new grid rollout, we deliver on time. This reliability has made us a trusted partner for utility contractors worldwide.

Conclusion

The integrity of an electrical network is defined by its smallest components. The Brass Parallel Groove Connector is a small device with a massive responsibility. It bridges the gap between power generation and consumption. By choosing a high-quality brass solution, utilities ensure safety, efficiency, and durability.

From the robust design that bites through oxidation to the high-grade alloy that resists corrosion, every aspect of the EPCOM connector is engineered for performance. When paired with our other solutions, such as the PA500 Tension Clamp or the versatile TTD Insulation Piercing Connector, you build a grid that is ready for the future.

Don’t leave your connections to chance. Invest in the reliability of EPCOM brass connectors and secure your power lines against the elements and time. Excellence in connectivity is not just our promise; it is our standard.