Fiber Optic Longitudinal Slitter: Top Solutions

Fiber Optic Longitudinal Slitter tools are essential instruments in the modern telecommunications landscape, serving as the cornerstone for efficient and safe cable management. In the rapidly evolving world of data transmission, network technicians face the constant challenge of accessing optical fibers without causing damage to the delicate glass cores inside. Whether you are working on a long-haul backbone project or a local FTTH (Fiber to the Home) installation, the precision of your stripping tools determines the quality of your connection.

For professionals in the field, time is money. However, precision is priceless. The traditional methods of using utility knives or generic wire strippers often result in fiber damage, leading to signal loss or expensive rework. This is where specialized tools from EPCOM come into play. By utilizing a dedicated slitting device, technicians can perform mid-span access on loose tube cables with surgical accuracy. This article delves deep into the mechanics, benefits, and best practices of using these tools, ensuring your toolkit is equipped for success.

What is a Fiber Optic Longitudinal Slitter?

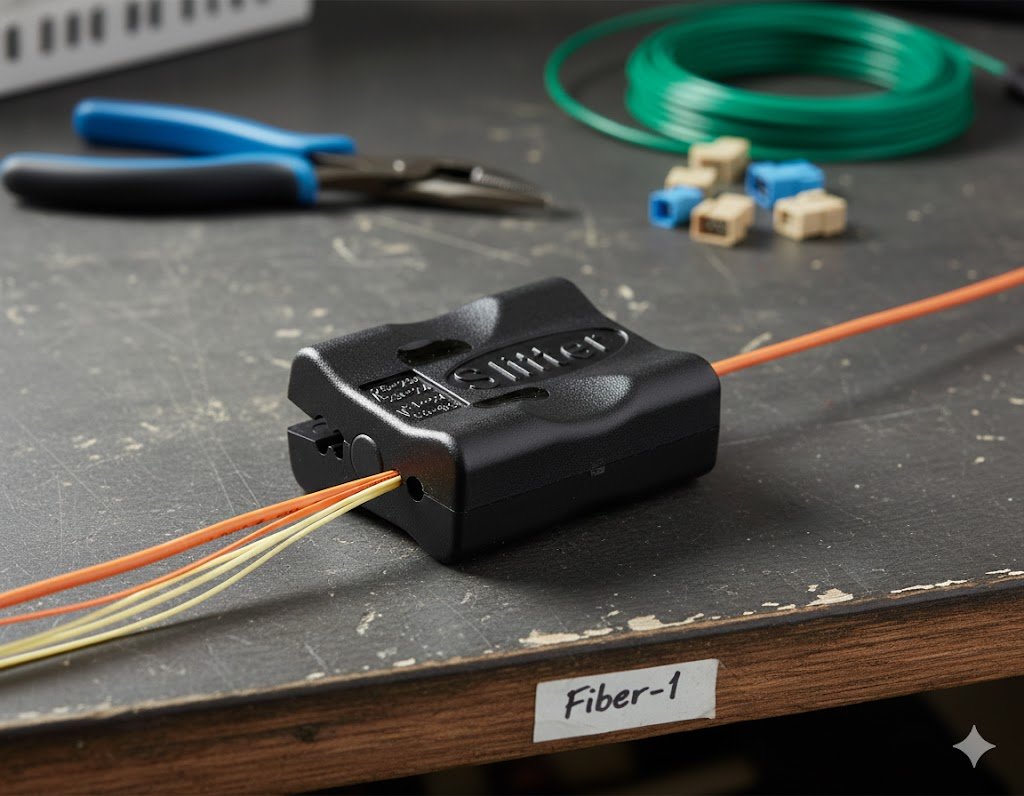

A Fiber Optic Longitudinal Slitter is a precision-engineered mechanical device designed to slit the outer jacket of fiber optic cables along their longitudinal axis. Unlike circumferential cutters, which slice around the cable, a longitudinal slitter runs parallel to the fiber. This specific action is crucial for “mid-span access,” a technique where a technician needs to access specific fibers within a cable run without cutting the entire cable.

These tools typically feature adjustable blades constructed from high-grade steel or alloys. The adjustability is a critical feature, allowing the user to set the blade depth precisely to match the jacket thickness. If the blade is too deep, it risks nicking the buffer tubes or the fibers themselves. If it is too shallow, the jacket won’t separate cleanly. Therefore, the design of a high-quality slitter focuses on depth control and stability.

Furthermore, the evolution of jacket materials—from polyethylene (PE) to Low Smoke Zero Halogen (LSZH)—demands tools that are durable enough to maintain a sharp edge. The modern slitter is not just a knife; it is a calibrated instrument. For example, when dealing with complex armored cables, standard tools fail. You need robust solutions like the 4.5-29mm Round Cable Stripper, which EPCOM offers to handle larger diameters and tougher materials effectively.

Why Use a Fiber Optic Longitudinal Slitter?

The primary reason for adopting a professional slitter is risk mitigation. Fiber optics are inherently fragile. A microscopic scratch on the glass surface can propagate into a crack over time, leading to catastrophic network failure. Manual stripping methods rely heavily on the operator’s steady hand, introducing human error. A specialized tool removes this variable.

Additionally, efficiency is a major driver. Imagine stripping 100 meters of heavy-duty cable jacket manually. It is physically exhausting and slow. With a proper tool, the process becomes seamless. You simply clamp the tool onto the cable and pull. The reduction in labor time is significant, allowing teams to complete installations faster.

Efficiency with a Fiber Optic Longitudinal Slitter

When we analyze workflow efficiency, the data is clear. Using the correct tool transforms a complex task into a routine operation. The blade geometry is designed to lift the jacket away from the core as it cuts, minimizing friction. This is particularly important for gel-filled cables where the internal friction can be high.

Moreover, versatility adds to the efficiency. Many modern tools are designed to handle a wide range of cable diameters. This means a technician doesn’t need to carry a dozen different tools up a utility pole. A single, adjustable unit can often suffice for various cable types found in a single network infrastructure.

Time Comparison (Lower is Better)

Safety Score (Higher is Better)

*Comparison of time taken to strip 3 meters of armored jacket and safety rating.

Types of Fiber Optic Longitudinal Slitter Tools

Not all cables are created equal, and neither are the tools used to strip them. Understanding the different categories of slitters is vital for selecting the right equipment for your specific job site. Generally, these tools can be categorized based on the cable structure they are designed to address.

First, we have the Buffer Tube Slitters. These are smaller precision tools designed for the thin tubes that house individual fibers. They are critical for the final stage of preparation before splicing.

Second, we have the Heavy Duty Jacket Slitters. These are robust tools meant for the outer polyethylene or PVC jackets. They often feature ratcheting mechanisms or sturdy handles to help the technician apply the necessary force to cut through thick protective layers.

To explore a comprehensive range of these specialized devices, you can visit our category page dedicated to the fiber cable slitter. Here, EPCOM provides solutions that cater to both delicate indoor riser cables and rugged outdoor armored cables.

Spotlight: The Round Cable Stripper

Among the various options available, the round cable stripper stands out for its versatility. Specifically, models capable of handling diameters from 4.5mm up to 29mm are incredibly useful for backbone infrastructure.

The mechanics of this tool allow for both circumferential (ringing) cuts and longitudinal (slitting) cuts. This dual functionality is essential. Typically, a technician will make a ring cut at the end of the section to be removed, and then a longitudinal slit to peel the jacket open like a banana.

The EPCOM 4.5-29mm Round Cable Stripper features an adjustable blade depth knob. This allows for micro-adjustments up to 3mm in depth. This level of control is necessary when moving between different manufacturers of fiber cable, as jacket thickness can vary slightly even within the same cable specification.

Features of a Premium Fiber Optic Longitudinal Slitter

What separates a generic tool from a professional grade one? It often comes down to the materials used. High-carbon steel blades retain their sharpness significantly longer than standard stainless steel. A dull blade is dangerous; it requires more force to cut, increasing the likelihood of the tool slipping and damaging the cable or injuring the user.

Ergonomics also play a vital role. Technicians often work in awkward positions—atop ladders, inside manholes, or in cramped server closets. A tool that fits comfortably in the hand and requires less grip strength reduces fatigue and the risk of Repetitive Strain Injury (RSI).

Step-by-Step: Using a Fiber Optic Longitudinal Slitter

Proper technique is just as important as the tool itself. Below is a detailed guide on how to perform a mid-span access safely.

- Preparation: Clean the cable jacket to remove dirt, grease, or gel. Debris can interfere with the blade’s path and dull the edge.

- Measurement: Mark the section of the cable where the jacket needs to be removed. Use a white marker for high visibility on black PE jackets.

- Depth Setting: Test the blade depth on a scrap piece of cable if available. If not, start with a shallow setting and increase incrementally. The goal is to cut almost through the jacket without touching the shielding or buffer tubes. Ideally, leave a thin layer of jacket that can be torn manually.

- Ring Cut: Perform a circumferential cut at the marked endpoints.

- Longitudinal Slit: Engage the longitudinal blade. Position the tool at the start mark and pull firmly and steadily towards the end mark. Maintain a consistent angle.

- Removal: Peel back the jacket. It should separate cleanly. If it requires excessive force, the blade depth may be too shallow.

Safety When Handling a Fiber Optic Longitudinal Slitter

Safety is paramount. Always wear safety glasses. While the slitter cuts the plastic, the glass fibers inside are hazardous. Fiber shards can penetrate the skin easily and are difficult to remove. Furthermore, when stripping armored cables, the metal edges can be extremely sharp.

Additionally, refer to standard industry protocols. Organizations such as the Fiber Optic Association (FOA) provide extensive guidelines on fiber optic safety standards that every technician should know.

Complementary Tools: Optical Fiber Cleavers

Once the jacket is successfully removed using your slitter, the job is not done. The exposed fibers must be prepped for splicing or termination. This involves stripping the coating, cleaning the glass, and finally, cleaving.

A slitter prepares the cable, but a cleaver prepares the glass. The quality of the cleave—the angle and smoothness of the glass end-face—directly impacts the signal loss at the splice point. Even the best stripping job is wasted if the cleave is poor. Therefore, pairing your slitter with a high-precision optical fiber cleaver is essential for a low-loss network.

Comparing Fiber Optic Longitudinal Slitter Models

To help you understand the market landscape, we have compiled a comparison of different slitter types. This table highlights the key differences between standard and advanced models.

| Feature | Standard Stripper | EPCOM Advanced Slitter |

|---|---|---|

| Blade Material | Stainless Steel | Hardened Carbon Alloy |

| Cable Capacity | Fixed Diameter | Adjustable (4.5mm – 29mm) |

| Cutting Direction | Ring Only | Longitudinal & Spiral |

| Ergonomics | Basic Handles | Anti-slip Grip Design |

| Safety Mechanism | Exposed Blade | Recessed/Guarded Blade |

Maintenance of Your Fiber Optic Longitudinal Slitter

A tool is only as good as its condition. Regular maintenance extends the life of your equipment and ensures consistent performance. The most critical component is the blade. Over time, cutting through tough PE jackets and metallic shielding will dull even the best alloys.

Check the blade visually before every use. Look for chips or rolls in the edge. If the blade is dull, do not force the tool; replace the blade immediately. EPCOM tools are designed with replaceable blades, making this a cost-effective maintenance strategy compared to buying a whole new tool.

Furthermore, keep the tool clean. Gel filling compounds used in outdoor cables are sticky and attract dust. This mixture can gum up the adjustable mechanisms, making it difficult to set the blade depth accurately. Clean the tool with Isopropyl Alcohol after working with gel-filled cables.

Troubleshooting Common Issues

If you find that the slit is uneven, check the cable guide mechanism. The cable must sit firmly in the channel for the blade to track straight. If the cable is slipping, increase the tension or double-check that you are using the correct setting for that specific cable diameter.

Industry Applications for Fiber Optic Longitudinal Slitter

The applications for these tools are vast. In the telecommunications sector, they are indispensable for deploying 5G networks, which require high-density fiber backbones. The ability to access fibers mid-span allows for flexible network architecture, enabling drops to new cell towers without severing the main line.

In the energy sector, Optical Ground Wire (OPGW) and All-Dielectric Self-Supporting (ADSS) cables are used on power lines. These cables have exceptionally thick and durable jackets to withstand environmental stress. Specialized heavy-duty slitters are required here to penetrate the outer layers without damaging the fibers that carry critical control data for the power grid.

Data centers also rely on these tools. While indoor cables are generally lighter, the sheer volume of connections means that efficiency is key. Preparing trunk cables for distribution frames requires clean cuts to maintain fire safety ratings and signal integrity. For further reading on cable specifications, the ITU-T G.652 standards offer detailed insights into the physical properties of single-mode optical fiber and cable.

Conclusion

In conclusion, the Fiber Optic Longitudinal Slitter is more than just a cutter; it is a gateway to the information superhighway. Choosing the right tool impacts the speed of installation, the safety of the technician, and the long-term reliability of the network.

EPCOM is committed to providing top-tier solutions for telecom professionals. Whether you need a versatile round cable stripper, a precision cleaver, or a comprehensive toolkit, our products are engineered to meet the rigorous demands of the field. By investing in quality tools and following best practices for maintenance and operation, you ensure that every connection you make is strong, stable, and built to last.

Equip yourself with the best. Explore the EPCOM catalog today and elevate your fiber optic installation capabilities to the next level.