Maximizing Networks with PLC Splitter Technology

A PLC Splitter stands as a cornerstone component in modern fiber optic networks, serving as a powerful and efficient solution for signal distribution. At its core, this device, based on Planar Lightwave Circuit (PLC) technology, is a passive optical component designed to divide a single or dual optical input into multiple output signals. This capability is absolutely fundamental for creating point-to-multipoint network architectures, which are prevalent in today’s data-driven world. Consequently, the importance of a high-quality PLC splitter cannot be overstated, particularly in the expansion of Fiber to the Home (FTTH) and Passive Optical Network (PON) systems globally. As a leading provider of robust telecommunication solutions, EPCOM is committed to delivering top-tier fiber optic components, including a comprehensive range of PLC splitters engineered for reliability, performance, and scalability.

Understanding the Fundamentals of the PLC Splitter

To fully appreciate the impact of the PLC splitter, it is essential to first understand the technology that powers it and the mechanism by which it operates. This foundational knowledge helps network engineers and technicians make informed decisions when designing, building, and maintaining sophisticated optical infrastructures. The elegance of the technology lies in its precision, stability, and compact form factor, all of which contribute to its widespread adoption.

What is Planar Lightwave Circuit (PLC) Technology?

Planar Lightwave Circuit (PLC) technology is a sophisticated manufacturing process that borrows techniques from the semiconductor industry to create highly precise optical components. The process involves depositing layers of silica glass onto a silicon or quartz substrate to form optical waveguides. These waveguides, which are microscopic channels for light, are meticulously etched and patterned using photolithography. This method allows for the creation of very precise and complex optical circuits in a compact and highly repeatable manner.

The result is a monolithic chip that can perform various optical functions, with signal splitting being the most common application. Because the entire splitter circuit is fabricated on a single, solid substrate, it is inherently stable and robust. This manufacturing precision ensures that the light is divided with exceptional uniformity and minimal loss, making the PLC splitter an incredibly reliable device. Furthermore, this technology allows for the integration of many splitters into a small physical footprint, a critical feature for high-density networking environments.

How a PLC Splitter Divides Optical Signals

The primary function of a PLC splitter is to take one or two input light signals and divide them among multiple output fibers. For instance, a 1×8 PLC splitter takes a single input signal and splits it into eight identical output signals. Similarly, a 2×64 splitter would take two inputs and distribute them across sixty-four outputs. The division of the optical power is designed to be exceptionally uniform, meaning each output port receives an equal share of the input signal’s power, minus the inherent optical loss.

You can visualize this process like a carefully engineered water distribution system. A large main pipe (the input fiber) channels water into a manifold (the PLC chip), which then precisely divides the flow into several smaller, identical pipes (the output fibers). In the case of a PLC splitter, this division happens with photons instead of water. This passive splitting process requires no external power, which significantly increases network reliability and reduces operational costs. The common split ratios include 1×2, 1×4, 1×8, 1×16, 1×32, and 1×64, providing network designers with the flexibility to serve various numbers of endpoints from a single fiber source.

Key Advantages of Using a PLC Splitter in Your Network

The adoption of PLC splitters in fiber optic networks is driven by a host of compelling advantages. These benefits translate directly into more reliable, scalable, and cost-effective network designs. For any organization looking to build or upgrade its fiber infrastructure, understanding these advantages is key to maximizing return on investment and ensuring future readiness.

High Reliability and Stability of PLC Splitter Tech

Reliability is arguably the most critical attribute of any network component. PLC splitter technology excels in this area due to its solid-state construction and passive nature. These devices have a very wide operating temperature range, typically from -40°C to 85°C, making them suitable for deployment in harsh indoor and outdoor environments. Moreover, they are insensitive to variations in wavelength, meaning they perform consistently across the entire spectrum used in telecommunications (e.g., 1260nm to 1650nm). This broad operational window ensures stable performance for various applications like standard data, video, and RFoG (Radio Frequency over Glass). The low failure rate of a PLC splitter minimizes network downtime and reduces maintenance expenses over the long term.

Compact Size for High-Density Applications

As data centers and network distribution hubs become more crowded, the physical size of components is a major consideration. PLC splitters offer a significant advantage with their compact form factor. The underlying PLC chip is incredibly small, allowing manufacturers to house splitters in various space-saving packages. Whether it’s a miniature steel tube splitter designed to fit inside a splice tray or a high-density 1U rack-mount unit that can accommodate dozens of connections, there is a PLC splitter configuration for nearly any space constraint. This compactness is vital for deploying large-scale FTTH networks where thousands of connections must be managed within limited physical space in central offices or street cabinets.

Cost-Effectiveness and Scalability with a PLC Splitter

For networks requiring a large number of splits, PLC splitters provide an exceptionally cost-effective solution. The semiconductor-like manufacturing process is highly scalable, which drives down the cost per port as the split ratio increases. While the initial investment for a high-ratio splitter exists, the cost to serve each individual endpoint becomes very low. This economic efficiency makes it feasible to build extensive passive optical networks. Additionally, PLC splitters enable easy network scalability. A network can be designed with splitters in a centralized or cascaded architecture, allowing for straightforward expansion as the subscriber base grows without requiring a complete overhaul of the existing fiber infrastructure.

PLC Splitter vs. FBT (Fused Biconical Taper) Splitter

When selecting an optical splitter, network designers typically choose between two primary technologies: PLC and FBT (Fused Biconical Taper). While both serve the same basic function of dividing an optical signal, they are based on different manufacturing processes and possess distinct characteristics. Understanding these differences is crucial for selecting the right component for a specific application. FBT is a more traditional technology that involves physically twisting, heating, and pulling two or more fibers together until they fuse. As they are pulled, the light is able to couple from one fiber core to the others.

Below is a comparative analysis to highlight the key distinctions:

| Feature | PLC Splitter | FBT Splitter |

|---|---|---|

| Manufacturing Process | Photolithographic process on a silica glass substrate (semiconductor-like). | Fusing and tapering two or more fibers together. |

| Operating Wavelength | Broadband (1260nm – 1650nm). Wavelength insensitive. | Optimized for specific wavelengths (e.g., 1310nm, 1490nm, 1550nm). Performance varies outside these windows. |

| Split Ratio Uniformity | Excellent. The signal is divided very evenly across all outputs. | Good, but generally less uniform than PLC, especially for higher split counts. |

| Available Split Ratios | Standard symmetric ratios up to 1×128 or 2×64. | Primarily lower split counts (e.g., 1×2, 1×3, 1×4). Can be customized for asymmetric ratios (e.g., 70/30). |

| Physical Size | More compact, especially for higher split counts. | Can become bulky as the split count increases. |

| Cost | More cost-effective for split counts greater than 1×4. | Typically lower cost for small split counts (1×2, 1×4). |

| Reliability | Very high due to monolithic chip design and fewer failure points. | Good, but the fused area can be a potential point of failure. |

When to Choose a PLC Splitter

A PLC splitter is the superior choice for most modern, large-scale network applications. Specifically, you should opt for a PLC splitter when:

- High Split Counts are Needed: For any application requiring more than four outputs, PLC technology is more reliable, compact, and cost-effective. It is the standard for PON and FTTH networks serving many subscribers.

- Consistent Performance is Critical: The excellent uniformity of a PLC splitter ensures that every end-user receives a signal of similar strength, simplifying network design and troubleshooting.

- Multiple Wavelengths are in Use: If your network transmits different services on different wavelengths (e.g., 1310nm for upstream data, 1490nm for downstream data, and 1550nm for video), the wavelength-insensitive nature of a PLC splitter guarantees stable performance for all services.

Deep Dive into PLC Splitter Configurations and Types

PLC splitters are not one-size-fits-all. They come in a wide variety of package types and connector options to suit different installation environments and network requirements. EPCOM offers a comprehensive portfolio of these configurations to ensure our clients have the exact component needed for their specific project, from large-scale data centers to rugged outdoor enclosures.

Exploring Different PLC Splitter Package Types

The packaging of a PLC splitter is crucial as it determines how the component is protected and integrated into the network. Each type is designed for a specific application scenario:

- Bare Fiber Splitter: This is the most basic form, consisting of the PLC chip with input and output fiber pigtails. It is extremely compact but offers no mechanical protection. It’s designed to be spliced and placed inside a protected enclosure like a splice cassette or termination box.

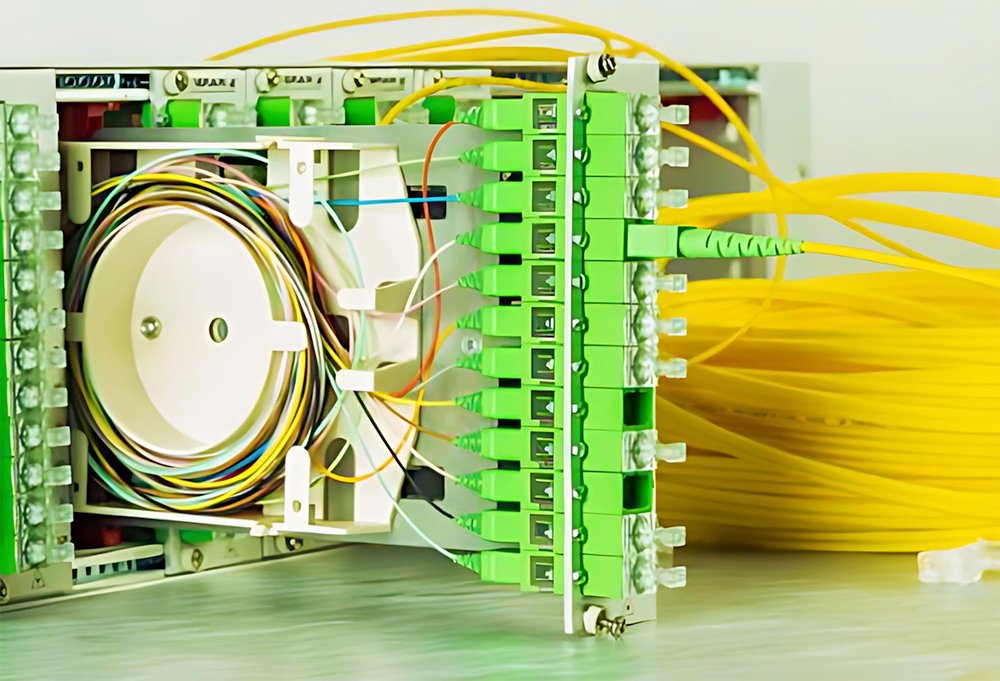

- Blockless / Mini Steel Tube Splitter: This type encloses the PLC chip and fibers in a ruggedized, small-diameter steel tube. It provides better protection than the bare fiber version and is small enough to be easily installed in fiber splice trays, wall-mount boxes, or other compact modules.

- ABS Box Splitter: This configuration houses the splitter in a durable ABS plastic box. It offers excellent protection for the inner optical components and fibers. ABS box splitters are very common and versatile, often used in standard 19-inch rack units or outdoor distribution cabinets. They typically come with pre-terminated connectors for easy plug-and-play installation.

- Rack-Mount Splitter: Designed for seamless integration into data center and central office racks, these splitters are housed in a standard 19-inch metal enclosure (typically 1U or 2U high). They provide a clean, organized, and high-density solution for managing a large number of splits in a centralized location.

- LGX Cassette Splitter: The LGX (Light Guide Cross-connect) module is a standardized, modular cassette format. An LGX PLC splitter can be easily snapped into an LGX-compatible patch panel or chassis. This modularity allows for flexible and scalable network designs, making it simple to add or change splitters as needed.

Understanding PLC Splitter Connector Types

The connectors on the ends of the splitter’s fibers are what allow it to be linked to the rest of the network. The choice of connector depends on the equipment and patch panels being used. An excellent resource for understanding the nuances of different connectors is the Fiber Optic Association’s online reference guide. Common types include:

- SC (Subscriber Connector): A widely used push-pull connector known for its good performance and ease of use. Its square shape allows for dense mounting.

- LC (Lucent Connector): A small form-factor connector that is very popular in high-density applications like data centers. It uses a latching mechanism and is roughly half the size of an SC connector.

- FC (Ferrule Connector): A threaded connector that provides a very secure and vibration-resistant connection. It is often used in testing equipment and single-mode applications requiring high precision.

- ST (Straight Tip): This connector uses a bayonet-style mount for a secure connection. While older, it is still found in some legacy multimode networks and industrial applications. To integrate components with this connector type, an ST Fiber Optic Adaptor is often required to mate two ST cables or connect an ST cable to a device with a different interface. Adaptors play a crucial role in ensuring interoperability within a diverse fiber optic infrastructure.

The Role of the PLC Splitter in Modern Networks

The PLC splitter is not just a component; it is an enabler of the network architectures that define modern connectivity. From delivering high-speed internet to homes to enabling next-generation mobile services, its role is both fundamental and expanding.

PLC Splitters in Passive Optical Networks (PON)

A Passive Optical Network (PON) is a telecommunications network architecture that brings fiber optic cabling and signals all or most of the way to the end user. It is called “passive” because the ODN (Optical Distribution Network) between the service provider’s central office and the user’s premises contains no active electronic components. The PLC splitter is the heart of the ODN.

In a typical PON, a high-capacity fiber line runs from the provider’s Optical Line Terminal (OLT). A PLC splitter then takes this single signal and divides it to serve multiple Optical Network Units (ONUs) or Optical Network Terminals (ONTs) located at or near subscriber locations. This point-to-multipoint topology, enabled by the splitter, drastically reduces the amount of fiber and central office equipment required compared to a point-to-point architecture. Standards like GPON (Gigabit PON) and EPON (Ethernet PON), which are detailed under the IEEE 802.3 Ethernet in the First Mile standard, heavily rely on the efficiency and reliability of PLC splitters.

Essential for Fiber to the Home (FTTH) Deployments

Fiber to the Home (FTTH) is the gold standard for residential and business internet connectivity, offering unparalleled speed and bandwidth. The economic and logistical feasibility of large-scale FTTH deployments hinges on the use of PON and, by extension, PLC splitters. By allowing a single feeder fiber from the central office to be split to serve up to 64 or even 128 homes, providers can significantly reduce the cost and complexity of installation. This shared infrastructure model is what has made the global expansion of fiber broadband possible, bringing gigabit speeds to millions of users.

Visualizing PLC Splitter Performance: Insertion Loss

One of the most critical performance metrics for a PLC splitter is its insertion loss, which measures the amount of signal power lost as the light passes through the device. The theoretical loss increases as the split ratio goes up, simply because the input power is being divided among more outputs. The chart below illustrates the typical maximum insertion loss values (in decibels, dB) for common PLC splitter ratios, as specified by industry standards. Lower values are always better.

How to Select the Right PLC Splitter for Your Needs

Choosing the correct PLC splitter requires a careful evaluation of several factors, from network topology to performance requirements and the physical environment. Making the right choice upfront ensures optimal performance and minimizes the need for costly future modifications.

Evaluating Key Performance Parameters of a PLC Splitter

Beyond the split ratio, several optical parameters define the quality and performance of a PLC splitter. It is crucial to check these specifications to ensure the component meets your network’s loss budget and performance standards:

- Insertion Loss (IL): As discussed, this is the reduction in signal power resulting from the insertion of the splitter. It is the most critical parameter and must be within the acceptable limits for the network’s power budget.

- Uniformity: This measures the maximum variation in insertion loss between all the output ports of a single splitter. A low uniformity value (e.g., < 0.6 dB) is desirable as it means all outputs receive a very similar amount of power.

- Return Loss (RL): This is a measure of the amount of light that is reflected back towards the source. A high return loss (e.g., > 55 dB) is better, as it indicates less back reflection, which can destabilize the light source and cause errors.

- Polarization Dependent Loss (PDL): This specifies the variation in insertion loss as the polarization state of the input light changes. A low PDL is important for networks carrying high-speed or analog signals that are sensitive to polarization.

- Directivity: This measures the amount of light that is sent to an incorrect output port. High directivity is important to prevent crosstalk between channels.

Installation and Best Practices for PLC Splitters

Proper installation and handling are paramount to realizing the full performance and lifespan of a PLC splitter. Even the highest-quality component can underperform if not installed correctly. Adhering to best practices protects the network investment and ensures long-term reliability.

Integration into Network Infrastructure

The physical placement and protection of the splitter are critical. In many field applications, the splitter and its associated splices must be housed in a secure enclosure. A component like EPCOM’s Protection Box with Adaptor is designed specifically for this purpose. These boxes shield the sensitive optical components from moisture, dust, and physical impact, which are common threats in outdoor or industrial environments. Ensuring the splitter is securely mounted within such an enclosure prevents stress on the fibers and connectors, which is a common cause of signal degradation and failure.

Testing and Troubleshooting Common PLC Splitter Issues

After installation, testing is required to verify performance. An Optical Power Meter (OPM) and Optical Light Source (OLS) are used to measure the actual insertion loss of each port and confirm it aligns with the expected values. For more advanced diagnostics, an Optical Time-Domain Reflectometer (OTDR) can be used to pinpoint the location of faults like bad splices, tight bends, or dirty connectors. The most frequent problems are often the simplest to solve: ensuring all connectors are perfectly clean before mating is the single most important step in preventing high loss and poor performance.

The Future of Optical Splitting and PLC Technology

The demand for bandwidth continues to grow exponentially, driven by trends like 5G, the Internet of Things (IoT), and cloud computing. PLC splitter technology is evolving to meet these challenges, ensuring it remains a critical enabler of next-generation networks.

Supporting Next-Generation Networks (5G, IoT)

5G wireless networks require a dense fiber backhaul infrastructure to connect the massive number of small cells. PLC splitters are ideal for distributing the fiber connections to these cells from a central point. Similarly, as the IoT connects billions of devices, the need for robust, high-capacity networks will grow. PLC splitters provide the scalable and cost-effective fiber foundation needed to support this massive connectivity. As these networks become more complex, managing the physical fiber layer becomes more challenging. High-density cabling solutions are essential. This is where products like the MPO/MTP Patch Cord become invaluable. These multi-fiber connectors can handle 12, 24, or more fibers in a single interface, dramatically simplifying the process of connecting high-capacity equipment that is fed by the outputs of PLC splitters, thereby saving space and reducing installation time.

Why Choose EPCOM for Your PLC Splitter Needs?

In conclusion, the PLC splitter is an indispensable component in the architecture of modern optical networks. Its ability to reliably and efficiently distribute optical signals is the foundation upon which FTTH, PON, and 5G networks are built. With superior uniformity, broad wavelength performance, and a compact design, PLC technology offers a scalable and cost-effective solution for meeting the world’s ever-increasing bandwidth demands.

At EPCOM, we understand the critical role that every single component plays in the overall health and performance of your network. That is why we offer a meticulously engineered and tested range of PLC splitters, alongside a complete ecosystem of fiber optic solutions, from protective enclosures to high-density patch cords and precision adaptors. Our commitment to quality ensures that when you choose EPCOM, you are building a network that is not only powerful today but also ready for the challenges of tomorrow.

Contact EPCOM’s team of experts today to discuss your specific network requirements and discover how our high-performance PLC splitters can form the reliable backbone of your fiber optic infrastructure.