Optical Fiber Cleaner: The Ultimate Pro’s Handbook

An Optical Fiber Cleaner is the single most important tool for maintaining the health and performance of any fiber optic network. In today’s hyper-connected world, where data speed and reliability are paramount, even a microscopic speck of dust on a fiber optic connector can bring communications to a grinding halt. This comprehensive article delves deep into the world of fiber optic cleaning, exploring why it’s non-negotiable, the different types of cleaners available, and how to use them effectively. Furthermore, we will highlight how premier tools from EPCOM create a complete ecosystem for fiber optic installation and maintenance, ensuring every connection you make is perfect from the start. Understanding the proper use of a fiber optic cleaner isn’t just a best practice; it is the cornerstone of a robust and efficient network infrastructure.

The Unseen Enemy: Why Fiber Optic Contamination is a Critical Issue

To truly appreciate the necessity of an optical fiber cleaner, one must first understand the incredible precision involved in fiber optics. A single-mode fiber core is typically only 9 micrometers in diameter—about one-tenth the width of a human hair. Light signals travel through this minuscule core, and any obstruction, no matter how small, can scatter, block, or reflect these signals. Consequently, this leads to significant performance degradation that can be incredibly difficult to troubleshoot without the right approach.

Contaminants are the invisible saboteurs of network performance. They come in many forms, including dust particles (often electrostatically attracted to the ferrule end-face), oils from human skin, residue from cleaning solvents, and moisture. When a contaminated connector is mated with another, the debris can be embedded into the fiber end-face, causing permanent damage like pits and scratches. Therefore, a proactive cleaning strategy is not just about performance; it’s also about protecting valuable network hardware from irreversible harm.

The two primary consequences of dirty connectors are insertion loss and back reflection. Insertion loss is the reduction of signal power resulting from the obstruction, weakening the signal as it passes through the connection. Back reflection, or return loss, occurs when light is reflected back towards the source. This reflected light can destabilize laser light sources and corrupt the data signal, leading to high bit error rates (BER). In analog systems, like those used for video transmission, this can cause visible picture degradation. In digital systems, it results in data loss, packet errors, and slower network speeds. Ultimately, investing in a high-quality optical fiber cleaner is one of the most cost-effective measures to prevent these costly issues.

Your Essential Toolkit: Exploring Types of Optical Fiber Cleaner

The market offers a variety of optical fiber cleaner tools, each designed for specific applications and connector types. Choosing the right one is crucial for achieving a perfect clean without damaging the delicate fiber end-face. At EPCOM, we provide a curated selection of professional-grade tools designed for reliability and ease of use. Let’s explore the most common and effective types of cleaners that every technician should have in their kit.

The Versatile One-Click Fiber Optic Cleaning Pen

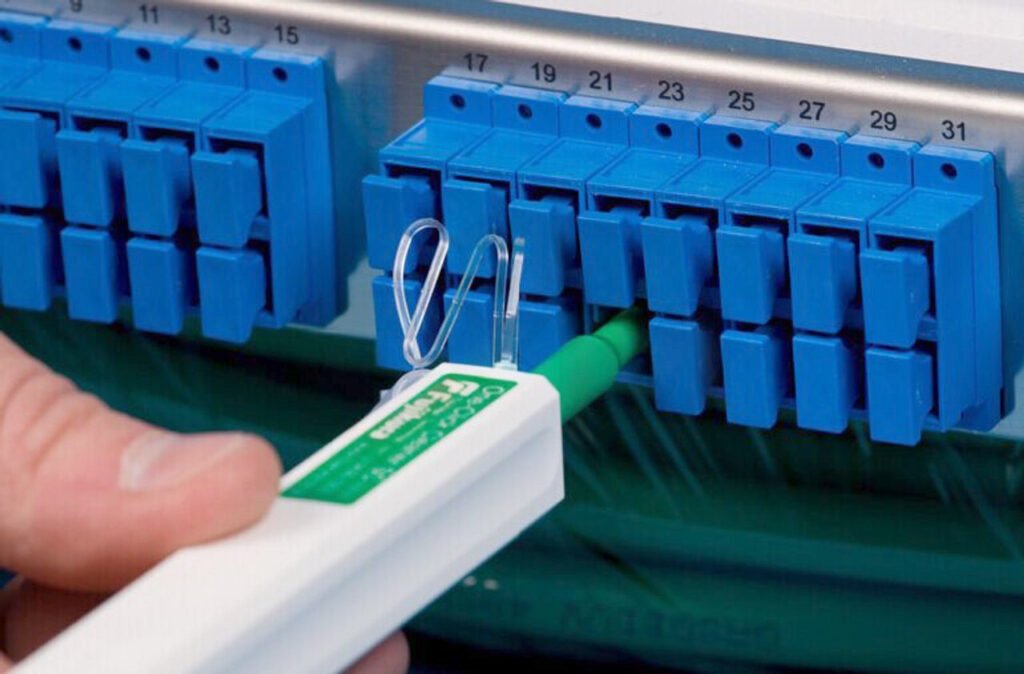

The “one-click” or “pen” style optical fiber cleaner is arguably the most popular and user-friendly tool available. Its design is brilliant in its simplicity. With a single press, a micro-woven cleaning strand is advanced and rotated against the connector end-face, effectively wiping away contaminants. This mechanism ensures that a fresh cleaning surface is used for every application, preventing cross-contamination.

These pens are designed to be used on both unmated connectors (patch cords) and connectors within bulkheads or adapters. They come in various sizes to match specific connector types, such as 2.5mm pens for SC, FC, and ST connectors, and 1.25mm pens for LC and MU connectors. Their key advantages are speed, convenience, and consistency. A technician can clean multiple ports in a fraction of the time it would take with manual methods. For instance, cleaning the ports in a high-density patch panel becomes a quick and efficient task. This makes the one-click optical fiber cleaner an indispensable tool for data center technicians, field installers, and maintenance crews.

High-Performance Cassette Optical Fiber Cleaner

For high-volume cleaning tasks, the cassette-style optical fiber cleaner is an excellent choice. This device contains a reel of high-density, lint-free cleaning cloth in a compact, hand-held case. The user simply presses the connector end-face against the exposed cloth window and swipes it in one direction. With each swipe, a lever advances the reel, exposing a fresh section of cleaning cloth. This design guarantees that contaminants are lifted and removed, not just smeared around.

Cassette cleaners provide a wide, flat cleaning surface, making them ideal for a variety of connector types, including MPO/MTP multi-fiber connectors. Many models are refillable, making them an economical and environmentally friendly option for large-scale operations. The enclosed design also protects the cleaning cloth from environmental contaminants until the moment it’s used. This type of optical fiber cleaner provides exceptional reliability and is a staple in manufacturing facilities and labs where pristine connections are required for testing and assembly.

Precision Cleaning with Fiber Optic Wipes and Solvents

While dry cleaning methods (using pens and cassettes) are effective for removing static-charged dust and light debris, more stubborn contaminants like oils, grease, or buffer gel require a “wet-to-dry” cleaning approach. This involves using a specialized, fast-evaporating fiber optic cleaning solvent with lint-free wipes. The process is meticulous: a small area of the wipe is moistened with the solvent, the connector end-face is drawn across the wet area, and then immediately drawn across a dry area of the same wipe. This “wet-to-dry” motion dissolves the contaminant and then lifts it away before the solvent can evaporate and leave a residue.

It is absolutely critical to use only purpose-made, lint-free wipes and electronic-grade solvents. Standard wipes or cloths can leave behind lint, and impure solvents like rubbing alcohol can leave a residue that impairs signal performance. When performed correctly, this method provides the most thorough clean possible and is often considered the gold standard for critical connections. It is important to follow industry best practices, such as those outlined by standards bodies like the Fiber Optic Association (FOA), to ensure the technique is effective and safe for the equipment.

The “Inspect, Clean, Inspect” Mantra: A Four-Step Process

The professional standard for handling fiber optic connectors is not just to clean them, but to follow a systematic process of inspection and verification. Simply using an optical fiber cleaner without checking your work is like working in the dark. The industry-wide best practice is “Inspect, Clean, Inspect,” a simple yet powerful mantra that guarantees a perfectly clean connection every time.

- Step 1: Inspect Before You Connect. The first rule of fiber handling is to assume that every connector is dirty, even brand-new ones right out of the bag. Dust caps can trap debris and manufacturing processes can leave behind residue. Using a professional fiber inspection scope, magnify the end-face (typically 200x or 400x) to check for any contaminants or damage. If it’s clean, you can proceed to connect. If it’s dirty, you must clean it.

- Step 2: Clean with the Right Tool. Based on the type of contaminant and connector, choose the appropriate optical fiber cleaner. For loose dust, a one-click pen or cassette cleaner is usually sufficient. For oily residue or embedded debris, a wet-to-dry cleaning with wipes and a solvent is necessary. Always follow the manufacturer’s instructions for the specific cleaning tool you are using.

- Step 3: Re-Inspect. After cleaning, you must inspect the connector end-face again with the scope. This step is non-negotiable. It verifies that the contaminant has been successfully removed and that the cleaning process itself did not introduce any new debris or cause damage. If the connector is still not clean, repeat the cleaning process, perhaps switching from a dry to a wet method.

- Step 4: Connect. Only after you have verified a clean end-face should you proceed to mate the connectors. This disciplined process eliminates contamination as a variable, making network turn-up faster and drastically reducing future troubleshooting time.

Advanced Scenarios for Your Optical Fiber Cleaner

While cleaning a standard patch cord connector is straightforward, real-world scenarios can be more complex. A skilled technician must know how to adapt their cleaning techniques for different situations. Having a versatile set of optical fiber cleaner tools is essential for tackling these challenges effectively and ensuring comprehensive network maintenance.

Maintaining Multi-Fiber Connectors with a Specialized Optical Fiber Cleaner

Multi-fiber Push-On (MPO/MTP) connectors are now standard in data centers for high-speed connectivity, such as 40G and 100G Ethernet. These connectors contain an array of fibers (12, 24, or more) in a single ferrule. A single speck of dust on one fiber can impact the entire connection. Cleaning these requires a specialized optical fiber cleaner designed for the wide surface area of the MPO ferrule. Cassette cleaners with a wide cleaning cloth are often effective, as are specialized MPO/MTP cleaning pens that are engineered to clean the entire array in one action. Due to the density of the fibers, inspection with an MPO-capable scope is even more critical than with single-fiber connectors.

An Optical Fiber Cleaner for Harsh Environments

Fiber optic networks are not confined to clean, temperature-controlled data centers. They are also deployed in challenging environments such as industrial manufacturing floors, outdoor cell towers, and military field operations. In these settings, connectors are exposed to dust, moisture, and industrial chemicals. Technicians working in these conditions need a robust optical fiber cleaner solution. This often means relying more heavily on wet-to-dry cleaning to remove stubborn industrial grime. Additionally, ruggedized cleaning kits that protect the tools and consumables from the elements are highly recommended. Keeping equipment clean in a harsh environment is a constant battle, but it is one that must be won to ensure network reliability.

Beyond Cleaning: EPCOM’s Ecosystem of Essential Fiber Tools

A pristine connection starts long before you reach for an optical fiber cleaner. It begins with proper cable preparation and termination. A successful fiber optic installation relies on an ecosystem of high-quality tools working together. At EPCOM, we understand this holistic approach and provide a complete range of tools that support every step of the process, ensuring the final connection is clean, clear, and strong.

First, consider the initial cable preparation. Before you can cleave or polish a fiber, you must access it. This requires a tool like the Flat Drop Wire Stripper. This specialized instrument is designed to safely and precisely remove the outer jacket and strength members from drop cables without nicking the delicate optical fiber within. A clean, careful strip is the foundation of a good termination. Using the wrong tool can damage the fiber, creating microscopic flaws that will compromise the connection, no matter how well you clean it later.

Next comes the most critical step in termination: cleaving the fiber. An Optical Fiber Cleaver is a high-precision tool that scores and breaks the glass fiber to create a perfectly flat end-face, perpendicular to the fiber axis. A poor cleave will result in a jagged, angled surface that cannot be properly mated, leading to massive signal loss and reflection. A high-quality cleaver from EPCOM ensures a consistently clean and precise cleave, which is the prerequisite for a low-loss connection. A well-cleaved fiber is also far easier to clean effectively with your optical fiber cleaner.

Finally, the connection is made using components like patch cords. Even a factory-terminated Fiber Patch Cord from EPCOM, manufactured and tested in a controlled environment, must be treated with care. While they arrive with protective dust caps, they should always be inspected and cleaned before their first use and as part of any ongoing maintenance. These components work together: a properly stripped cable, a precisely cleaved fiber, a high-quality connector, and a meticulous cleaning process, all contributing to a network that performs flawlessly.

Data and Performance: The Quantifiable Impact of Using an Optical Fiber Cleaner

The impact of contamination is not theoretical; it is measurable and significant. The following table illustrates the typical insertion loss values associated with common contaminants on a single-mode connector. As you can see, what might seem like a minor issue can easily push the signal loss beyond the acceptable limits for a given network link budget, as defined by standards from organizations like the Telecommunications Industry Association (TIA).

| Condition of Connector End-Face | Typical Insertion Loss (dB) | Performance Impact |

|---|---|---|

| Clean Connector | 0.1 – 0.3 dB | Excellent Performance |

| Minor Dust Particle (5µm) on Core | 0.5 – 1.5 dB | Significant Signal Degradation |

| Fingerprint Oil Smudge | 1.0 – 4.0 dB | Severe Degradation, Potential Link Failure |

| Embedded Debris from Mating Dirty | > 4.0 dB | Complete Link Failure, Permanent Damage |

Figure 1: Studies consistently show that contaminated connectors are the number one cause of network failures.

Choosing the Right Optical Fiber Cleaner with EPCOM

With a clear understanding of the importance of cleanliness and the tools available, the final step is selecting the right optical fiber cleaner for your specific needs. The choice depends on several factors:

- Connector Types: Do you primarily work with LC, SC, MPO, or other connectors? Ensure you have the correctly sized pens and adapters.

- Application Environment: Are you in a clean data center or a dusty field environment? This will influence whether dry or wet cleaning methods are more appropriate.

- Frequency of Use: For occasional use, a simple one-click pen may suffice. For high-volume work, a refillable cassette cleaner might be more economical.

At EPCOM, we provide not just the products, but the expertise to help you build the perfect cleaning and maintenance kit. Our range of optical fiber cleaner tools is selected for quality, reliability, and performance, ensuring that you can execute your work to the highest professional standards. By investing in quality tools from EPCOM, you are not just buying a cleaner; you are investing in the long-term reliability of your network.

In conclusion, the role of the optical fiber cleaner is not merely janitorial; it is fundamental to the very function of modern telecommunications. A clean connection is a reliable connection. By embracing the “Inspect, Clean, Inspect” methodology and equipping yourself with a comprehensive toolkit of high-quality strippers, cleavers, and cleaners from EPCOM, you empower yourself to build and maintain fiber optic networks that deliver the speed and stability the digital world demands. Do not let a microscopic particle be the cause of a macroscopic problem. Explore our range of telecom tools today and make every connection count.