Low-Loss Indoor GJFDBV Fiber Optic Cable

The Indoor GJFDBV Fiber Optic Cable is a high-performance cable designed for demanding indoor network applications. It offers superior transmission characteristics, exceptional durability, and easy installation, making it the ideal choice for data centers, office buildings, and home networks.

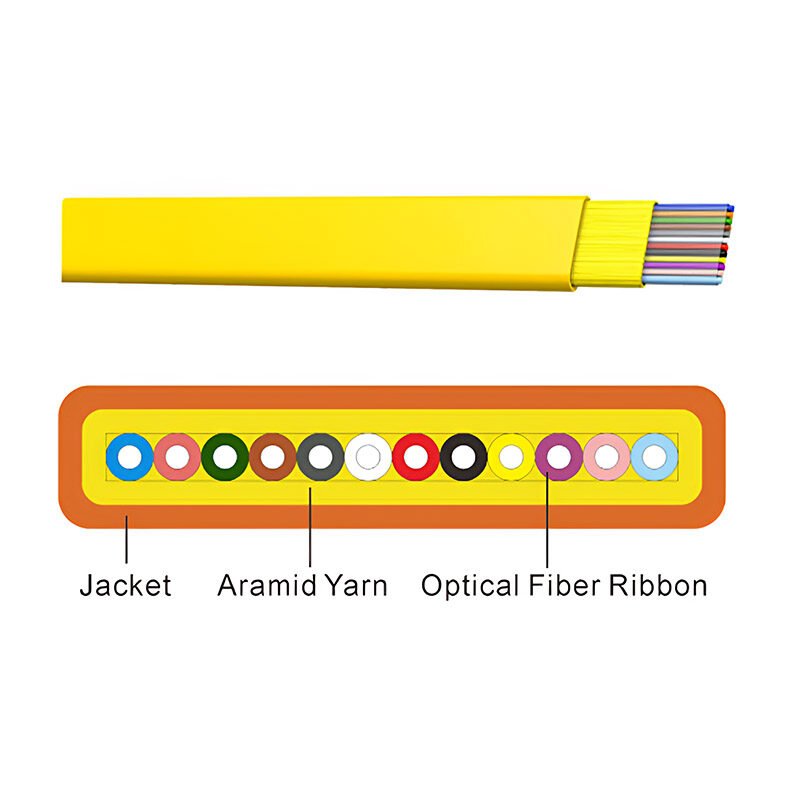

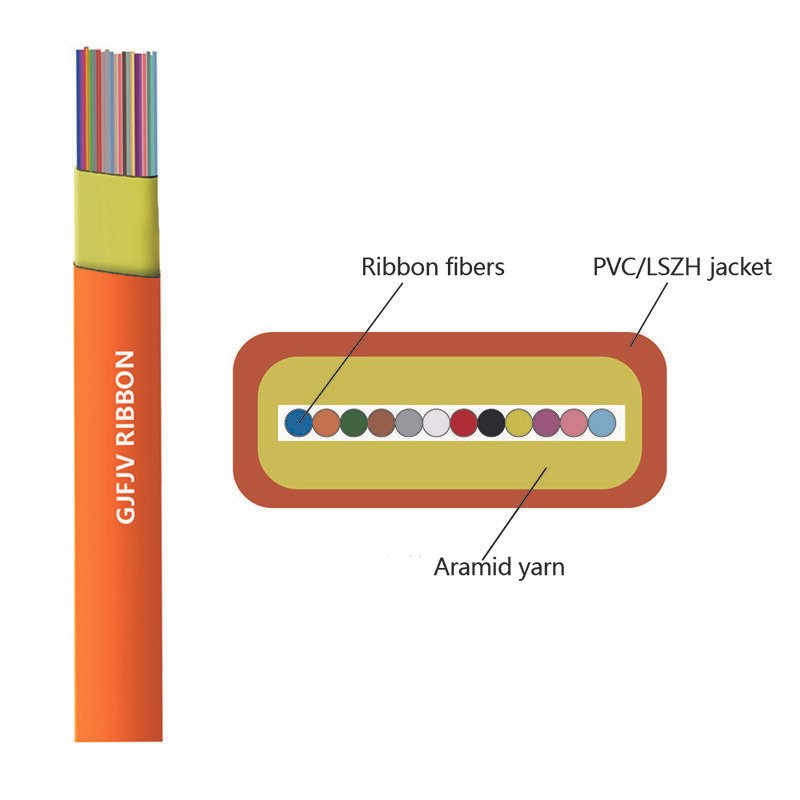

- Space-saving flat ribbon design optimizes cable management and facilitates mass fusion splicing.

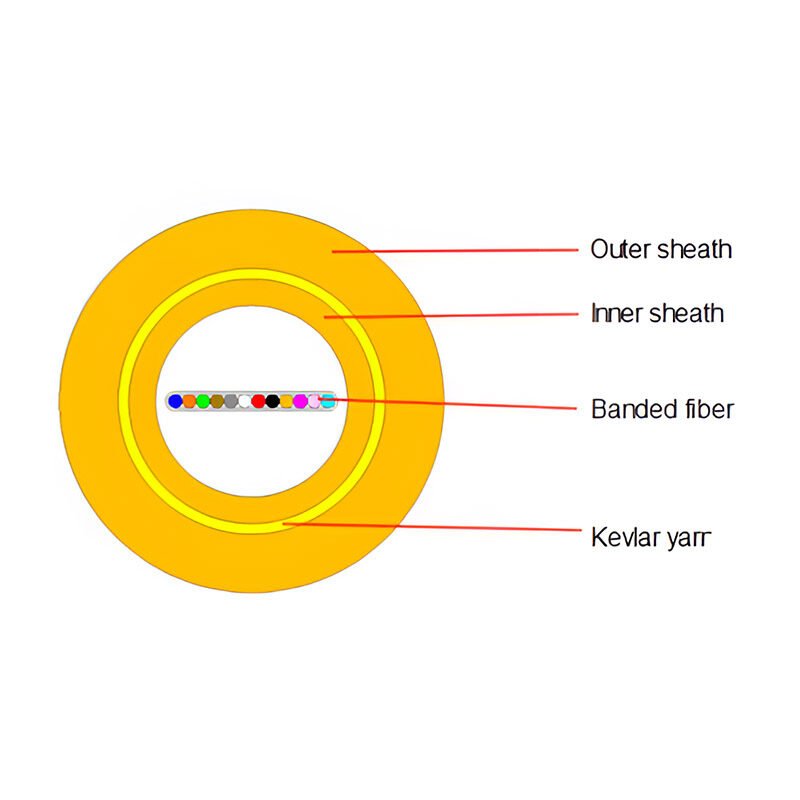

- High-modulus aramid yarn strength member provides superior tensile resistance without extra weight.

- Flame-retardant LSZH or PVC jacket ensures compliance with indoor fire safety building codes.

- Immune to electromagnetic interference for safe installation alongside electrical power conduits.

- Compatible with single-mode and multi-mode fibers for high-speed 40G and 100G Ethernet.

Description

The GJFDBV Fiber Optic Cable is a premier indoor cabling solution engineered by EPCOM to meet the rigorous demands of modern high-density data centers and telecommunication networks. As data transmission speeds continue to escalate, the need for reliable, space-efficient, and easy-to-install optical infrastructure becomes paramount. This flat ribbon optical cable is specifically designed to address these challenges, offering a superior balance of tensile strength, flexibility, and transmission efficiency.

By utilizing a flat structure design, this cable optimizes space utilization in crowded conduits and risers, making it an exceptional choice for inter-building backbones and intra-building distribution. Whether you are upgrading an existing enterprise network or deploying a new FTTX architecture, our indoor fiber solution ensures seamless connectivity and future-proof performance.

Engineering Excellence of the GJFDBV Fiber Optic Cable

The core construction of the GJFDBV Fiber Optic Cable sets it apart from conventional round cables. It features a specialized flat ribbon arrangement where high-quality optical fibers are precisely aligned. This configuration not only facilitates mass fusion splicing—significantly reducing installation time—but also enhances the cable’s ability to dissipate heat in high-load environments. The fibers are protected by a high-modulus aramid yarn strength member, which provides exceptional tensile resistance without adding unnecessary weight.

EPCOM has integrated a robust, flame-retardant jacket available in PVC or Low Smoke Zero Halogen (LSZH) materials. The LSZH sheathing is particularly critical for indoor applications, as it minimizes the release of toxic smoke and corrosive gases in the event of a fire, ensuring compliance with strict building safety codes. This meticulous engineering ensures that the cable maintains signal integrity even under mechanical stress or environmental fluctuations.

Optimizing Network Architecture with GJFDBV Fiber Optic Cable

In the landscape of structured cabling, versatility is key. The unique flat geometry of the GJFDBV Fiber Optic Cable allows for tighter bend radii and more efficient cable management within server racks and distribution frames. This is vital for network administrators looking to maximize airflow and minimize clutter in data centers.

Seamless Integration with Management Accessories

To fully leverage the performance of this optical cable, it is essential to employ high-quality termination and protection accessories. For residential or small office deployments, the cable can be effectively routed to a Protection Box with Adaptor. This integration safeguards the delicate fiber splice points from dust and physical damage while providing a clean interface for end-user connection.

Furthermore, when distributing connections to individual workstations or zones, the cable is perfectly dimensioned to terminate into a 4 Cores Fibre Optic Faceplate. This wall-mounted solution offers a neat, professional appearance and protects the fiber ends, ensuring reliable daily operation. The compatibility of our cable with these standard enclosures underscores its adaptability for diverse installation scenarios, from high-rise commercial buildings to residential complexes.

Technical Specifications

EPCOM ensures that every reel of cable meets international quality standards. Below are the detailed technical parameters designed to assist network engineers in planning their infrastructure.

| Parameter | Specification Details |

|---|---|

| Product Name | Indoor Flat Ribbon Optical Cable |

| Fiber Type | Single-mode (G.652D, G.657A) / Multi-mode (OM3, OM4) |

| Fiber Count | 4, 6, 8, 12, 24 Cores |

| Strength Member | High-Modulus Aramid Yarn |

| Sheath Material | Flame Retardant PVC or LSZH |

| Cable Dimensions (approx.) | Width: 2.5mm – 4.5mm; Height: 1.5mm – 2.5mm (Dependent on core count) |

| Tensile Strength (Long/Short Term) | 200N / 600N |

| Crush Resistance (Long/Short Term) | 300N / 1000N per 100mm |

| Bending Radius | Static: 10D; Dynamic: 20D (D = Cable Height) |

| Operating Temperature | -20°C to +60°C |

| Storage Temperature | -20°C to +60°C |

Connectivity and Termination Versatility

The flat ribbon structure of the GJFDBV Fiber Optic Cable simplifies the stripping and splicing process. Technicians can easily separate individual fibers for termination without specialized heavy tools. This cable is compatible with a wide array of industry-standard connectors. For legacy networks or specific industrial applications requiring bayonet-style locking mechanisms, the fibers can be terminated using a high-precision ST Fiber Optic Adaptor. This flexibility ensures that upgrading your network infrastructure with EPCOM cable does not require a complete overhaul of your existing hardware interfaces.

Installation and Handling Advantages

One of the primary challenges in indoor fiber deployment is navigating complex pathways without compromising the optical fiber’s physical integrity. The lightweight nature of this cable significantly reduces the load on cable trays and suspended ceilings. Unlike bulky, gel-filled outdoor cables, the dry-core design of the GJFDBV Fiber Optic Cable eliminates the need for messy cleaning solvents during preparation, speeding up the installation workflow by up to 30%.

The incorporation of aramid yarn not only provides tensile strength during the pulling phase but also adds a layer of dielectric protection. This means the cable is immune to electromagnetic interference (EMI), allowing it to be run safely alongside electrical power conduits without signal degradation. This feature is particularly beneficial in industrial settings or older buildings where cable pathway separation is difficult to achieve.

Reliability in GJFDBV Fiber Optic Cable Deployments

Reliability is the cornerstone of any EPCOM product. Our rigorous testing protocols ensure that each kilometer of cable delivers consistent attenuation performance across the entire operating temperature range. The uniform geometry of the ribbon structure guarantees low differential group delay (DGD), which is critical for supporting high-speed protocols such as 40G and 100G Ethernet.

By choosing a solution that prioritizes physical durability and optical precision, network operators can significantly reduce maintenance costs. The robust jacket resists abrasion and micro-bending losses, ensuring that the network remains active and efficient for decades. Whether used for vertical riser cabling or horizontal distribution, the stability of this cable underpins the reliability of the entire communication system.

Why Partner with EPCOM?

At EPCOM, we understand that cabling is the lifeline of your business operations. Our commitment extends beyond manufacturing; we provide comprehensive support to ensure your network architecture is optimized for performance and scalability. The GJFDBV Fiber Optic Cable represents our dedication to innovation in optical technology, combining ease of use with industrial-grade durability.

We strictly adhere to international standards such as ISO/IEC 11801 and TIA-568 to guarantee global compatibility. When you source your infrastructure components from us, you are investing in a verified, high-performance ecosystem. From the initial fiber selection to the final jacket extrusion, every step of our manufacturing process is monitored to deliver a product that exceeds expectations.

Upgrade your indoor network infrastructure today with EPCOM’s advanced cabling solutions. Experience the difference that professional-grade materials and precision engineering make in your daily data transmission and network stability.