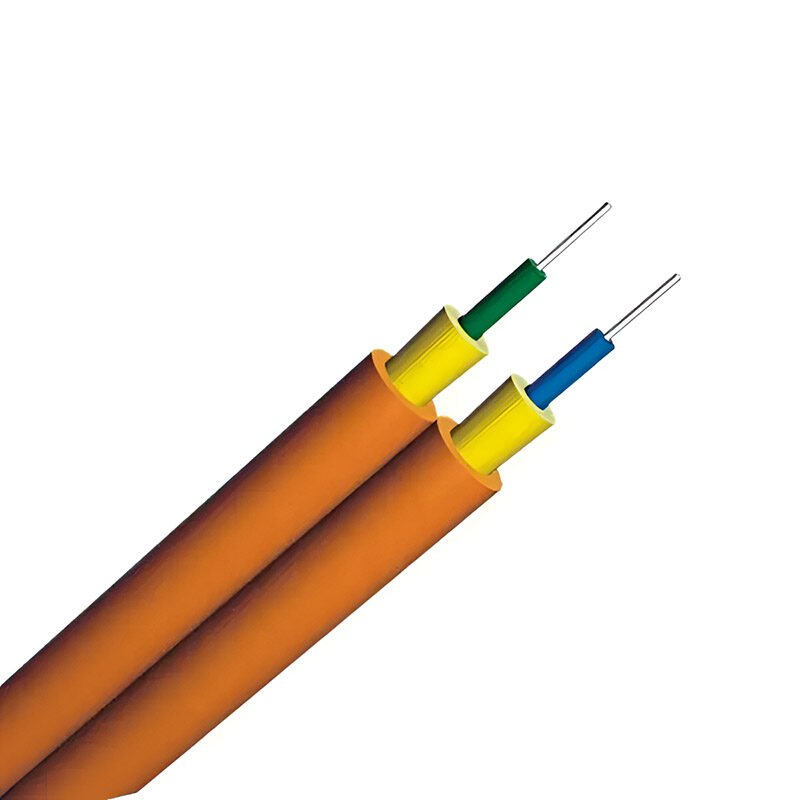

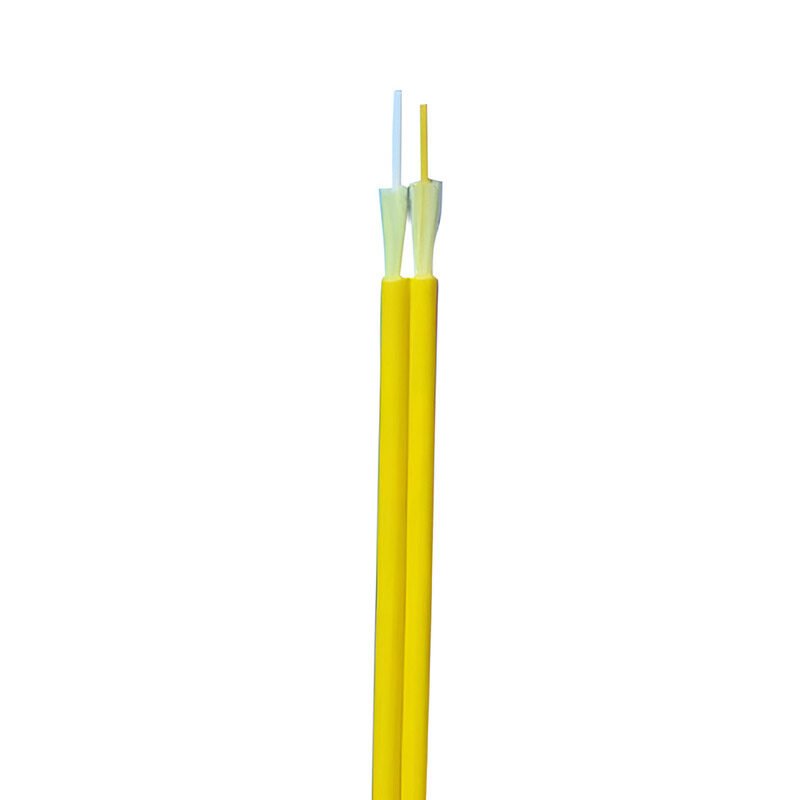

Durable Indoor GJFJBV Fiber Optic Cable

This premium indoor cable solution utilizes advanced fiber optic technology to deliver exceptional signal clarity and bandwidth, ideal for data centers, office buildings, and even future-proofing your home network. We’re referring to the GJFJBV Fiber Optic Cable, a high-performance option for data transmission applications.

- High-performance indoor interconnect solution

- Features LSZH (Low Smoke Zero Halogen) outer jacket

- Enhanced durability with Aramid Yarn strength members

- Available in Single-Mode and Multi-Mode fiber types

- Zipcord design for easy separation and termination

Description

The GJFJBV Fiber Optic Cable from EPCOM represents a pinnacle in indoor optical communication solutions. Engineered for reliability and high performance, this cable is specifically designed as a zipcord interconnect, making it an ideal choice for a multitude of indoor applications. Its robust construction ensures longevity, while its design prioritizes ease of installation and superior signal integrity. Whether for data centers, local area networks (LANs), or connecting telecommunication devices, the GJFJBV series delivers consistent and dependable performance. EPCOM is committed to providing high-quality optical fiber products that meet the rigorous demands of modern communication networks.

Understanding EPCOM’s GJFJBV Fiber Optic Cable

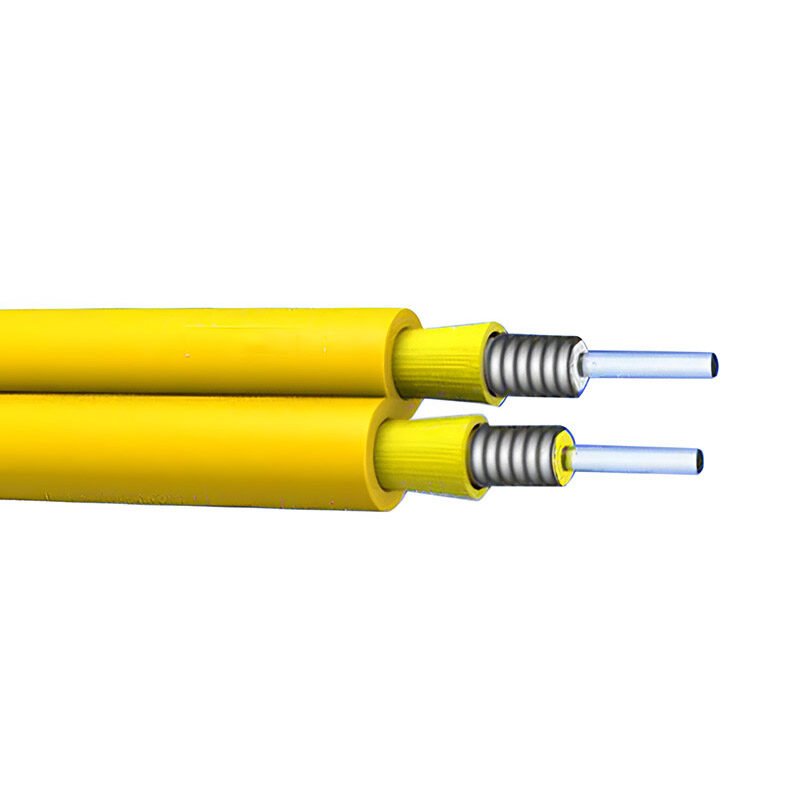

EPCOM’s GJFJBV Fiber Optic Cable is meticulously crafted to provide optimal performance for indoor environments. The “GJFJBV” designation typically indicates a tight-buffered duplex (two-fiber) construction, often in a zipcord (figure-8) configuration for easy separation of individual fiber units. This design is crucial for applications requiring discrete connections, such as patching or direct equipment links.

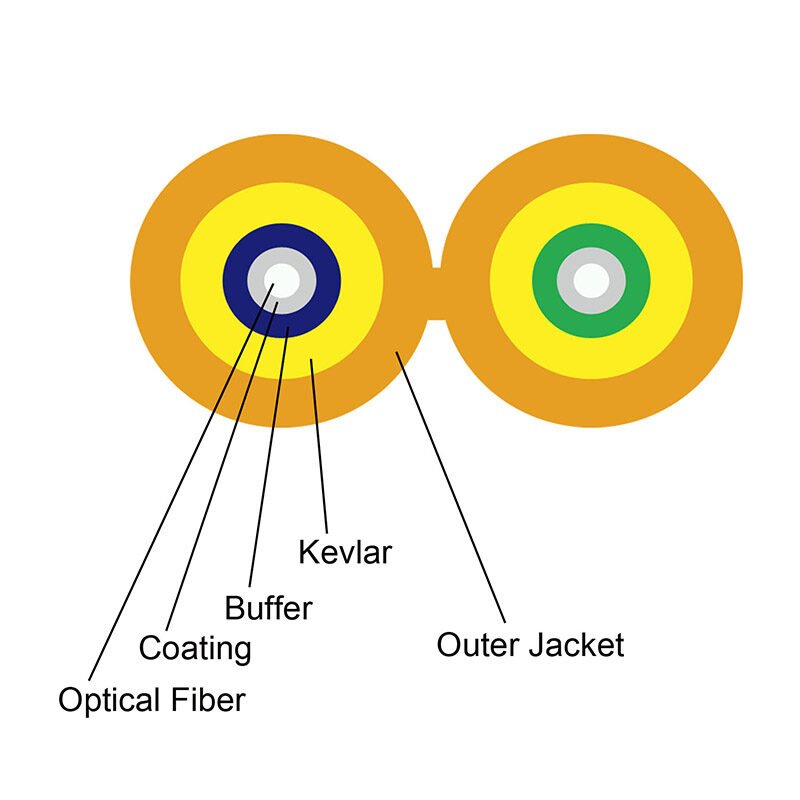

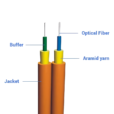

Core Structure and Materials

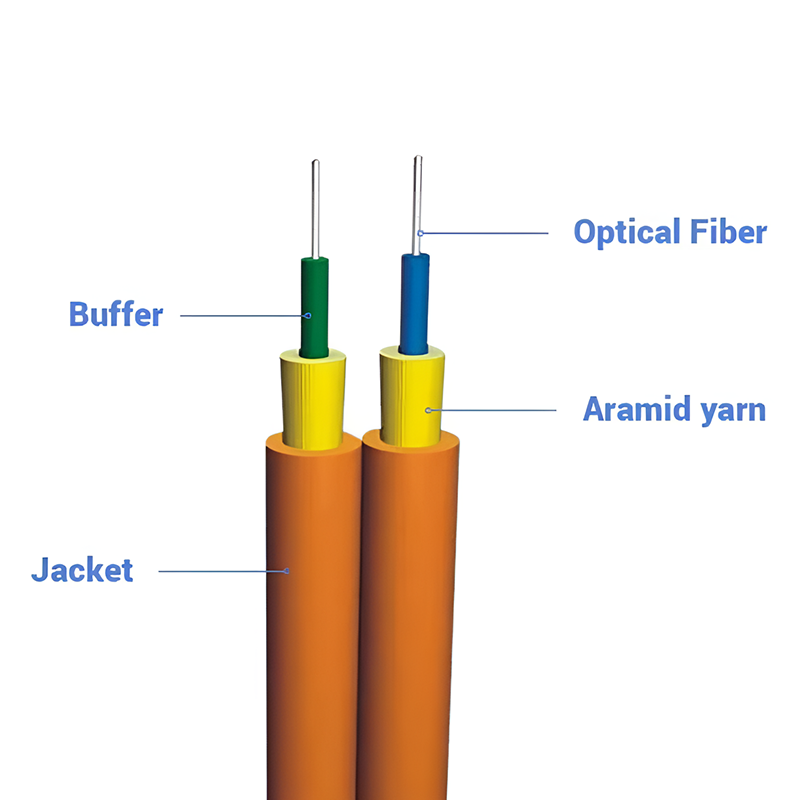

The internal structure of the GJFJBV cable is key to its performance and durability. Each optical fiber is protected by multiple layers:

- Optical Fiber Core: The central part of the cable, responsible for light transmission. EPCOM offers various fiber types, including bend-insensitive single-mode (e.g., G.657.A2) and multi-mode options.

- Coating: A primary protective layer applied directly to the glass fiber.

- Tight Buffer: A secondary polymer layer, typically 900µm, extruded over the coated fiber. This provides additional mechanical protection and allows for easier connectorization.

- Aramid Yarn: High-tensile strength members surrounding the buffered fibers. Aramid yarn provides excellent tensile strength during installation and protects the fibers from pulling forces.

- Outer Jacket: The outermost protective sheath, typically made from Low Smoke Zero Halogen (LSZH) material for indoor GJFJBV Fiber Optic Cable variants. LSZH jackets are flame-retardant and produce minimal smoke and no toxic halogen compounds when exposed to fire, enhancing safety in confined spaces.

The zipcord design allows the two simplex units to be easily separated by hand, simplifying the termination process for duplex connectors or individual simplex connectors.

Advanced Fiber Types in GJFJBV Fiber Optic Cable

EPCOM’s GJFJBV Fiber Optic Cable can be configured with various industry-standard fiber types to meet diverse application needs. These include:

- Single-Mode Fibers (SMF): Typically G.652.D for general applications or G.657 series (A1, A2, B3) for enhanced bend performance, crucial in tight installation spaces common for indoor cables. The G.657.A2 fiber, for instance, allows for smaller bend radii without significant signal loss, making it highly suitable for patch cords and interconnects made from GJFJBV Fiber Optic Cable.

- Multi-Mode Fibers (MMF): OM1, OM2, OM3, OM4, and OM5 options are available for shorter-reach applications within buildings and data centers. These fibers are characterized by their core diameters and bandwidth capabilities, supporting various data rates and distances.

The choice of fiber type depends on the specific requirements of the network, including transmission distance, bandwidth, and the equipment being connected. EPCOM ensures that all fibers used in its GJFJBV Fiber Optic Cable products meet stringent quality and performance standards.

Versatile Applications of GJFJBV Fiber Optic Cable

The inherent design of the GJFJBV Fiber Optic Cable makes it exceptionally versatile for a wide range of indoor networking scenarios. Its duplex zipcord configuration is particularly advantageous for applications requiring simultaneous two-way communication. The ease of handling and termination further broadens its applicability across different environments.

Ideal Use Cases for GJFJBV Indoor Cabling

The primary application area for GJFJBV Fiber Optic Cable is indoor environments where flexibility, ease of termination, and flame retardancy are important. Common uses include:

- Patch Cords and Jumper Cables: GJFJBV cables are extensively used to manufacture high-quality duplex patch cords for connecting network equipment within racks, data centers, and telecommunication closets.

- Workstation Connections (Fiber to the Desk): For providing high-bandwidth connectivity directly to user workstations in office environments.

- Interconnects within Equipment: Used for internal wiring within communication devices, servers, and switching hardware.

- Building Backbone Cabling: In smaller installations, it can serve as part of the building’s backbone infrastructure, connecting distribution points.

- LAN and Data Center Applications: Essential for establishing reliable links between servers, switches, storage area networks (SANs), and other critical data center components. The high bandwidth capacity of the GJFJBV Fiber Optic Cable supports the growing data demands in these facilities.

Interconnecting Communication Equipment

In modern telecommunication rooms and data centers, the GJFJBV Fiber Optic Cable is instrumental in creating reliable links. It facilitates connections between optical line terminals (OLTs), optical network units (ONUs), routers, switches, and media converters. The zipcord design allows for straightforward duplex connections, ensuring efficient data flow for both transmission and reception paths. Its compatibility with standard fiber optic connectors further enhances its utility in these settings.

Key Features and Benefits of This Cable Solution

EPCOM’s GJFJBV Fiber Optic Cable is not just a means of transmission but a comprehensive solution offering numerous advantages that contribute to a robust and efficient network infrastructure. These features are designed to address the practical challenges of indoor installations and the performance expectations of modern optical networks.

Enhanced Durability and Flexibility

Durability is paramount for any cabling solution. The GJFJBV Fiber Optic Cable incorporates aramid yarn as a strength member, providing significant tensile strength to withstand the rigors of installation without damaging the delicate optical fibers within. This makes the cable resilient during pulling through conduits or cable trays. Furthermore, the tight buffer construction offers an additional layer of protection to individual fibers, making them less susceptible to micro-bending and physical stress. The flexibility of the cable, especially when G.657 bend-insensitive fibers are used, allows for installation in space-constrained areas and around tight corners, which is common in equipment racks and office environments.

Superior Optical Transmission Quality with GJFJBV

The ultimate measure of a GJFJBV Fiber Optic Cable is its ability to transmit optical signals with minimal loss and distortion. EPCOM utilizes high-grade optical fibers that exhibit low attenuation and dispersion characteristics. This ensures that data can be transmitted reliably over the intended distances, maintaining signal integrity for high-bandwidth applications. The precision manufacturing process minimizes geometric imperfections in the fiber, contributing to consistent performance. When combined with proper termination and cleaning practices, this cable provides a clear and stable path for optical signals, supporting everything from internet access to high-speed data transfer and video streaming.

Detailed GJFJBV Fiber Optic Cable Specifications

The following table outlines typical specifications for EPCOM’s GJFJBV Fiber Optic Cable. Please note that specific parameters can be customized based on your unique requirements. Contact EPCOM for detailed datasheets and customization options.

| Parameter | Specification |

|---|---|

| Cable Type | GJFJBV (Duplex Zipcord Tight Buffer) |

| Fiber Type Options | Single-Mode (G.652.D, G.657.A1, G.657.A2, G.657.B3), Multi-Mode (OM1, OM2, OM3, OM4, OM5) |

| Number of Fibers | 2 (Duplex) |

| Buffer Diameter | 0.9mm ± 0.05mm per fiber |

| Strength Member | Aramid Yarn |

| Jacket Material | LSZH (Low Smoke Zero Halogen) |

| Jacket Color | Yellow (SM), Orange (MM OM1/OM2), Aqua (MM OM3), Erika Violet (MM OM4), Lime Green (MM OM5) – Customizable |

| Cable Dimensions (Nominal) | e.g., (1.6-3.0mm) x (3.4-6.2mm) – Varies with fiber count and jacket thickness |

| Attenuation (SM G.657.A2) | ≤ 0.35 dB/km @ 1310nm, ≤ 0.22 dB/km @ 1550nm |

| Operating Temperature | -20°C to +70°C |

| Installation Temperature | -5°C to +50°C |

| Minimum Bend Radius (Installation) | 20 x Cable Diameter |

| Minimum Bend Radius (Operation) | 10 x Cable Diameter (G.657.A2 allows for tighter bends) |

| Compliance | RoHS, IEC, ITU-T standards |

Essential Accessories for Optimal Performance

To fully leverage the capabilities of your GJFJBV Fiber Optic Cable and ensure a reliable, long-lasting installation, EPCOM recommends using high-quality compatible accessories. These components play a crucial role in termination, protection, and maintenance of your optical network.

Terminating Your Cable

Proper termination is critical for minimizing signal loss and ensuring a stable connection. The GJFJBV Fiber Optic Cable, with its tight-buffered fibers, is designed for easy connectorization. For quick and reliable field terminations, EPCOM suggests using our Square Type SC Fast Connectors. These connectors reduce installation time and do not require specialized polishing tools, making them ideal for indoor GJFJBV Fiber Optic Cable applications. Other connector types (LC, ST, FC) are also compatible, depending on your equipment interface.

Protecting and Organizing Connections

Once terminated, fiber optic connections need to be housed and protected. EPCOM offers a range of solutions, such as our 24-Cores Termination Box for Fiber Optics. These enclosures provide a secure environment for splices and connectors, protecting them from dust, physical damage, and environmental factors. Proper organization within these boxes also simplifies future maintenance and troubleshooting for your GJFJBV Fiber Optic Cable network.

Maintaining Signal Integrity with GJFJBV Fiber Optic Cable

Contamination is a leading cause of failure in fiber optic networks. Dust, oils, and other debris on connector end-faces can significantly degrade signal quality or block transmission entirely. Therefore, regular cleaning is essential. EPCOM strongly recommends using a One-Click Cleaner before every mating of connectors associated with your GJFJBV Fiber Optic Cable. These specialized tools are designed to effectively remove contaminants without damaging the delicate fiber end-face.

Installation and Maintenance Best Practices

Proper installation and diligent maintenance are crucial for maximizing the lifespan and performance of your GJFJBV Fiber Optic Cable infrastructure. Adhering to industry best practices will help prevent issues and ensure network reliability.

Handling and Installing GJFJBV Fiber Optic Cable

When installing GJFJBV Fiber Optic Cable, it’s important to observe the specified minimum bend radius to avoid causing attenuation or fiber damage. Avoid excessive pulling tension; use appropriate tools and techniques if pulling through conduits. The LSZH jacket provides good protection for indoor environments, but care should be taken to avoid sharp edges or crushing forces during and after installation. For comprehensive guidance on Fiber Optic Technology and installation, consult resources from organizations like The Fiber Optic Association (FOA).

During termination, ensure a clean working environment. Strip the cable and fibers according to the connector manufacturer’s instructions. As previously mentioned, cleaning connector end-faces before mating is a non-negotiable step for achieving optimal performance with any GJFJBV Fiber Optic Cable installation.

Regularly inspect patch panels and visible GJFJBV Fiber Optic Cable runs for any signs of damage, excessive bending, or stress. Test the network periodically with an Optical Loss Test Set (OLTS) or an OTDR to verify performance and identify any potential degradation before it impacts service. Keep connectors covered with dust caps when not in use to prevent contamination.

Why Choose EPCOM for Your Optical Fiber Needs?

EPCOM is dedicated to providing superior quality GJFJBV Fiber Optic Cable and a comprehensive range of fiber optic solutions. Our commitment extends beyond products to include expert support and a focus on customer satisfaction. We understand the critical role that reliable connectivity plays in today’s world, and our products are designed and manufactured to meet the highest industry standards. By choosing EPCOM, you are partnering with a company that prioritizes innovation, quality control, and responsive service, ensuring that your network infrastructure built with GJFJBV Fiber Optic Cable is robust, scalable, and future-proof.

For more information on our GJFJBV Fiber Optic Cable or to discuss your specific project requirements, please contact EPCOM today. Our team of experts is ready to assist you in selecting the ideal fiber optic solutions for your needs.