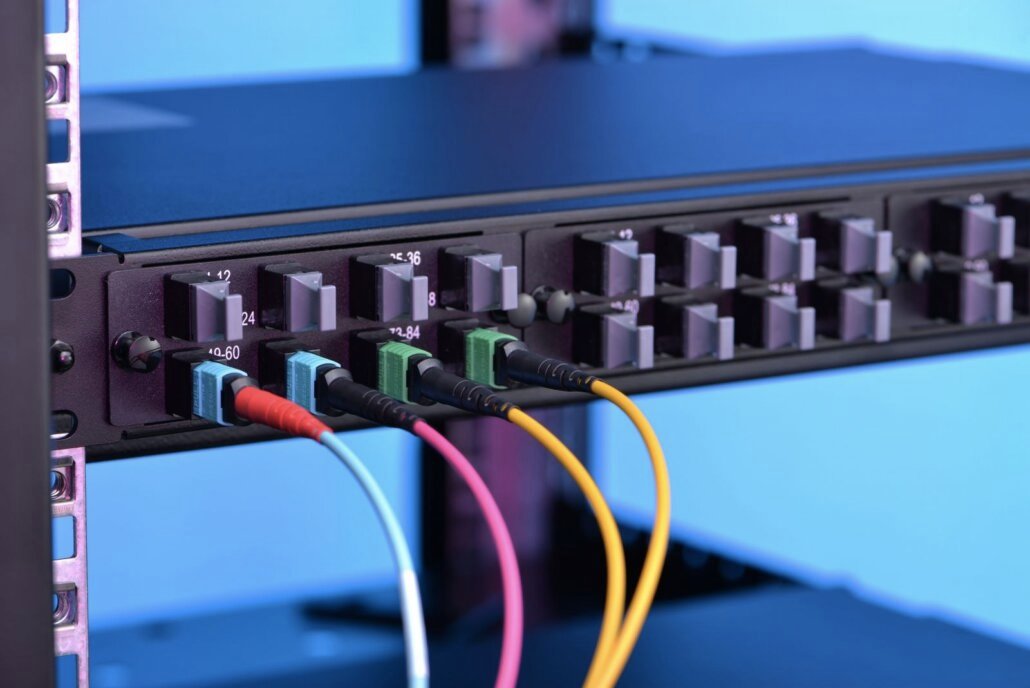

High-Density MPO/MTP Patch Cord for Data Centers

MPO/MTP Patch Cord, also known as MPO/MTP Trunk Cable, is a type of fiber optic cable that is designed to connect multiple MPO/MTP connectors together. It is a versatile and high-performance solution for a wide range of applications, including data centers, telecommunications networks, and enterprise networks.

- High-density fiber connectivity

- Multi-fiber push-on connectors (MPO/MTP)

- Supports 40G, 100G, 400G, 800G Ethernet

- Singlemode and multimode options

- Space optimization

- Rapid deployment

- Simplified cable management

- Scalable for future upgrades

- Low insertion loss

Description

MPO/MTP Patch Cord technology from EPCOM represents the forefront of high-density fiber optic cabling, designed to meet the escalating bandwidth demands of modern network infrastructures. These advanced multi-fiber assemblies are crucial components in enabling rapid deployment, superior performance, and simplified cable management in environments where space and efficiency are paramount. As data rates continue to climb, leveraging reliable MPO/MTP connectivity becomes essential for future-proofing network investments.

Understanding MPO/MTP Patch Cord

An MPO/MTP Patch Cord is a multi-fiber cable assembly terminated at either end with MPO (Multi-fiber Push-On) or MTP® (Multi-fiber Termination Push-on) connectors. The MTP® connector, a high-performance version developed by US Conec, offers enhanced mechanical and optical performance compared to the generic MPO standard but remains fully compatible and intermateable with MPO connectors. These connectors consolidate multiple fibers (typically 8, 12, 16, 24, or more) into a single interface, significantly increasing connection density compared to traditional single-fiber connectors like LC or SC.

This high-density nature makes MPO/MTP cable assemblies ideal for backbone cabling, data center interconnects, and parallel optics applications such as 40G, 100G, 400G, and even emerging 800G Ethernet transceivers. EPCOM provides robust and reliable MPO/MTP solutions tailored to diverse networking requirements.

Benefits of EPCOM’s MPO/MTP Patch Cord Solutions

Choosing EPCOM for your MPO/MTP cabling needs offers several distinct advantages:

- Space Optimization: By consolidating multiple fibers into a single connector, MPO/MTP patch cords drastically reduce the physical space required for cabling infrastructure in racks and pathways. This is particularly beneficial in crowded data centers and telecommunication rooms.

- Rapid Deployment: Pre-terminated MPO/MTP assemblies enable faster installation compared to field-terminating individual fibers. Plug-and-play functionality significantly reduces deployment time and labor costs.

- Simplified Cable Management: Fewer individual cables mean less clutter, easier routing, and improved airflow within cabinets and racks, contributing to better equipment cooling and easier maintenance access.

- Scalability and Future-Proofing: MPO/MTP infrastructure provides a clear migration path to higher data rates. Networks built with MPO/MTP backbones can easily upgrade from 10G to 40G, 100G, 400G, and beyond, often just by changing transceivers and patch cords or cassettes.

- Reliable High-Speed Performance: EPCOM’s MPO/MTP patch cords are manufactured using high-quality components and stringent testing procedures to ensure low insertion loss (IL) and high return loss (RL), critical for supporting demanding high-speed data transmission protocols.

- Cost-Effectiveness: While the initial cost per connector might seem higher, the overall cost of deploying a high-density MPO/MTP system (considering labor, pathway space, and scalability) is often lower than traditional cabling for high-bandwidth applications.

Applications for High-Density Fiber Optic Cables

MPO/MTP Patch Cords are versatile and find applications across various sectors:

- Data Centers: Core infrastructure for interconnecting servers, switches, storage area networks (SANs), and routers. Essential for Spine-Leaf architectures and high-density zones.

- Telecommunication Networks: Used in central offices, headends, and distribution points for high-capacity links.

- Enterprise Backbones: Connecting building distribution frames (BDFs) to intermediate distribution frames (IDFs) in large campus networks.

- High-Performance Computing (HPC): Facilitating high-speed, low-latency connections between computing clusters.

- Broadcasting and Content Delivery Networks (CDNs): Supporting the high bandwidth needed for video transport and distribution.

- Test and Measurement Labs: Providing flexible and high-density connectivity for optical equipment testing.

Types of MPO/MTP Patch Cords Available

EPCOM offers a comprehensive range of MPO/MTP patch cords to suit specific network designs. Key variations include:

Fiber Types (SM/MM)

- Singlemode (OS2): Typically with a yellow jacket, OS2 fiber is used for long-distance transmission and applications requiring the highest bandwidth potential, common in telecom and large data center backbones.

- Multimode (OM3, OM4, OM5): Primarily used for shorter distances within data centers and buildings.

- OM3 (Aqua jacket): Optimized for 10G Ethernet, supports 40G/100G up to 100 meters.

- OM4 (Aqua or Erika Violet jacket): Enhanced performance over OM3, supporting 40G/100G up to 150 meters.

- OM5 (Lime Green jacket): Wideband multimode fiber (WBMMF), designed to support Short Wavelength Division Multiplexing (SWDM) for increased capacity over fewer fibers, extending reach for 40G/100G/400G applications.

Understanding MPO/MTP Patch Cord Polarity

Polarity ensures that the transmitter at one end connects to the receiver at the other. The TIA-568 standard defines three methods:

- Method A (Straight-Through): Fiber 1 arrives at position 1, Fiber 2 at position 2, etc. Requires a cross-connect patch cord (A-to-A) at one end or within a cassette. Uses key-up to key-down adapters.

- Method B (Reversed/Crossed): Fiber 1 arrives at position 12, Fiber 2 at position 11, etc. Uses straight-through patch cords (B-to-B) throughout. Uses key-up to key-up adapters. This is common for direct 40/100G transceiver connections.

- Method C (Pairs Flipped): Adjacent fiber pairs are flipped (1-2 -> 2-1, 3-4 -> 4-3, etc.). Uses Type C trunks and straight-through patch cords. Uses key-up to key-down adapters.

EPCOM provides MPO/MTP patch cords configured for all standard polarity methods to ensure correct end-to-end connectivity.

Connector Gender Options

MPO/MTP connectors come in male (with guide pins) and female (without guide pins) versions. A connection always requires one male and one female connector mating. Patch cords are typically available as Female-Female (most common for patching), Male-Male (less common, sometimes used for specific equipment connections), or Male-Female (used as trunk extension cables).

Fiber Count Variations

While 12-fiber MPO/MTP connectors are the most prevalent, EPCOM also offers solutions based on:

- 8-fiber: Optimized for 40G (4x10G) and 100G (4x25G) SR4 applications, reducing unused fibers present in 12-fiber systems for these specific links.

- 16/24/32-fiber: Higher density connectors used for emerging standards like 400G/800G or ultra-high-density structured cabling.

Jacket Material Ratings

Cable jackets provide protection and must meet specific fire safety codes based on installation environment:

- LSZH (Low Smoke Zero Halogen): Emits minimal smoke and no toxic halogen compounds when exposed to fire. Required in many European regions and specific confined spaces.

- OFNP (Optical Fiber Non-conductive Plenum): Suitable for installation in plenum air spaces (e.g., above suspended ceilings) due to high fire resistance and low smoke characteristics. Highest fire rating.

- OFNR (Optical Fiber Non-conductive Riser): Suitable for vertical runs between floors in non-plenum environments. Intermediate fire rating.

Technical Specifications for MPO/MTP Patch Cords

EPCOM’s MPO/MTP patch cords meet rigorous performance criteria. Below are typical specifications:

| Parameter | Specification |

|---|---|

| Connector Type | MTP / MPO (Male/Female options) |

| Fiber Type | Singlemode (OS2 9/125µm), Multimode (OM3, OM4, OM5 50/125µm) |

| Polish Type | UPC (Multimode), APC (Singlemode, optional for Multimode) |

| Fiber Count | 8, 12, 16, 24 Fibers (Other counts available on request) |

| Insertion Loss (IL) – Typical | SM: ≤ 0.35dB (Elite/Low Loss: ≤ 0.25dB); MM: ≤ 0.25dB (Elite/Low Loss: ≤ 0.15dB) |

| Insertion Loss (IL) – Maximum | SM: ≤ 0.75dB (Elite/Low Loss: ≤ 0.35dB); MM: ≤ 0.50dB (Elite/Low Loss: ≤ 0.35dB) |

| Return Loss (RL) | SM APC: ≥ 60dB; SM UPC: ≥ 50dB; MM UPC: ≥ 30dB |

| Jacket Material | LSZH, OFNP (Plenum), OFNR (Riser) |

| Jacket Color | OS2: Yellow; OM3: Aqua; OM4: Aqua/Violet; OM5: Lime Green (Custom colors available) |

| Cable Diameter | Typically 3.0mm round cable (Microcore options available) |

| Operating Temperature | -20°C to +70°C |

| Durability | ≥ 500 matings |

| Compliance | IEC 61754-7, TIA-604-5 (FOCIS-5), RoHS Compliant |

Quality Assurance for EPCOM MPO/MTP Patch Cords

Quality is paramount at EPCOM. Our MPO/MTP patch cords undergo rigorous testing to guarantee performance and reliability:

- 100% Interferometer Testing: Verifies correct fiber end-face geometry (radius of curvature, apex offset, fiber protrusion/undercut) crucial for physical contact and low loss.

- Insertion Loss (IL) and Return Loss (RL) Testing: Each assembly is tested to ensure it meets or exceeds industry standards for optical performance. Test reports are available.

- Visual Inspection: Connectors are inspected under high magnification for scratches, defects, or contamination.

- Polarity Verification: Ensures the correct fiber mapping according to the specified polarity method (A, B, or C).

- Standards Compliance: Manufactured according to relevant IEC standards (like IEC 61754-7 for MPO connectors) and TIA/EIA standards (like TIA-604-5 FOCIS-5).

Essential Accessories for Your MPO/MTP Patch Cord Setup

To maximize the performance and longevity of your MPO/MTP infrastructure, consider these essential accessories from EPCOM:

- MPO/MTP Adaptors: These ensure precise alignment between two MPO/MTP connectors. Available in key-up to key-down (Type A/C systems) or key-up to key-up (Type B systems) configurations. Proper adapter selection is critical for maintaining polarity.

- MPO/MTP Cleaning Pens: Contamination is a major cause of network failures. Specialized click-style cleaners designed for MPO/MTP connector end-faces are vital for maintaining signal integrity before mating connectors. Regular cleaning prevents performance degradation.

- MPO/MTP Module Cassettes: These modules provide a bridge between MPO/MTP backbone cabling and traditional LC or SC equipment ports. They mount within fiber optic patch panels and break out the multi-fiber MPO/MTP connection into duplex single-fiber connections, simplifying patching and network management.

Using high-quality, compatible accessories ensures a reliable and easily manageable high-density cabling system.

Choosing the Right MPO/MTP Patch Cord

Selecting the appropriate MPO/MTP patch cord involves considering several factors:

- Application Data Rate: Determine the required speed (10G, 40G, 100G, 400G) as this influences fiber type and fiber count choices.

- Link Distance: Choose singlemode (OS2) for long reaches or the appropriate multimode grade (OM3, OM4, OM5) for shorter data center links.

- Fiber Type: Match the patch cord fiber type to the existing infrastructure or application requirements (OS2, OM3, OM4, OM5).

- Polarity Method: Ensure the patch cord polarity matches the trunk cables and equipment requirements (Type A, B, or C). Consistency is key.

- Fiber Count: Select 8, 12, 16, or 24 fibers based on the specific application (e.g., 8-fiber for 40G SR4, 12-fiber for general backbone or 100G SR10, higher counts for 400G+).

- Jacket Rating: Comply with local building codes by choosing the correct fire rating (LSZH, OFNP, OFNR).

- Connector Gender: Ensure correct male/female configuration for the connection point.

EPCOM’s technical team is available to assist you in selecting the optimal MPO/MTP patch cord configuration for your specific project needs.

Conclusion

EPCOM’s MPO/MTP Patch Cords provide a robust, scalable, and high-performance foundation for modern high-density networks. By simplifying deployment, optimizing space, and enabling seamless migration to higher speeds, our MPO/MTP solutions help organizations build reliable and future-proof network infrastructures. Trust EPCOM for quality components, rigorous testing, and expert support for all your fiber optic connectivity needs.

Contact EPCOM today to discuss your requirements or browse our extensive range of MPO/MTP products.