High-Strength Stay Plate for Grid Reliability

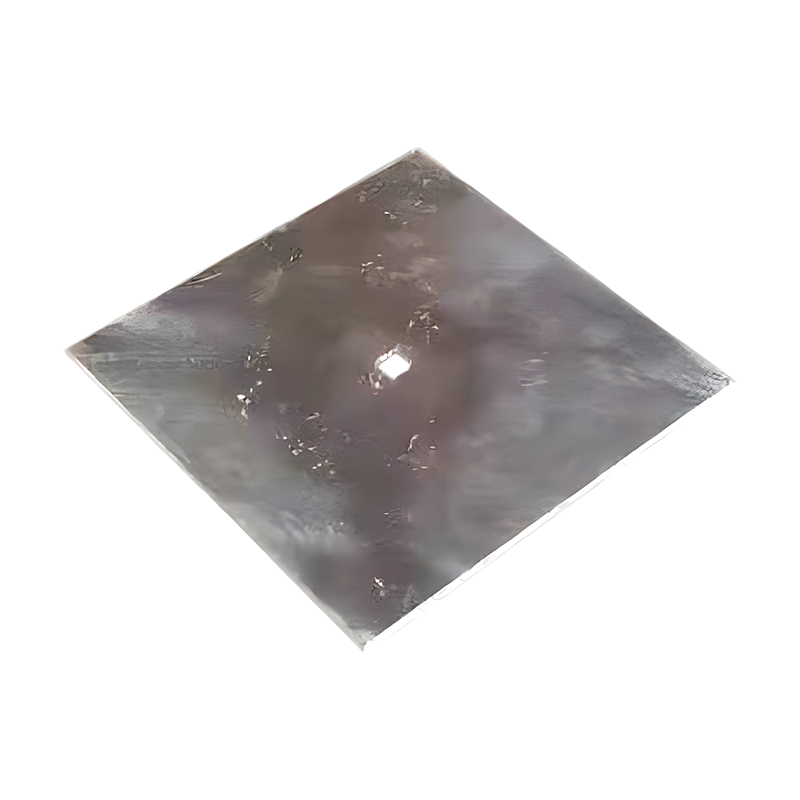

A Stay Plate is a flat, rectangular piece of stainless steel that is used to secure and reinforce various structures. It is commonly used in construction, manufacturing, and other industrial applications. Stay plates are known for their durability, strength, and resistance to corrosion. They are also easy to install and maintain.

- Superior Load Distribution: Engineered shape maximizes soil resistance and anchoring power.

- Extreme Durability: Fabricated from high-tensile structural steel to withstand immense forces.

- Maximum Corrosion Protection: Fully hot-dip galvanized finish ensures decades of reliable service.

- Versatile Sizing: Wide range of dimensions and thicknesses to match specific load requirements.

- Precision Engineering: Features a clean, central hole compatible with all standard stay rod diameters.

Description

A Stay Plate is a critical component in the assembly of stay systems, providing the foundational anchor for utility poles, transmission towers, and telecommunication masts. This component, also known as an anchor plate or guy plate, is specifically engineered to be buried in the ground. Its primary function is to effectively distribute the high-tensile load from the stay wire (or guy wire) over a large area of soil. This distribution prevents the anchor rod from pulling through the earth, thereby ensuring the stability and long-term integrity of the entire pole-line structure. At EPCOM, we prioritize grid reliability, and our stay plates are the first line of defense against structural failure.

Understanding the Function of a Stay Plate

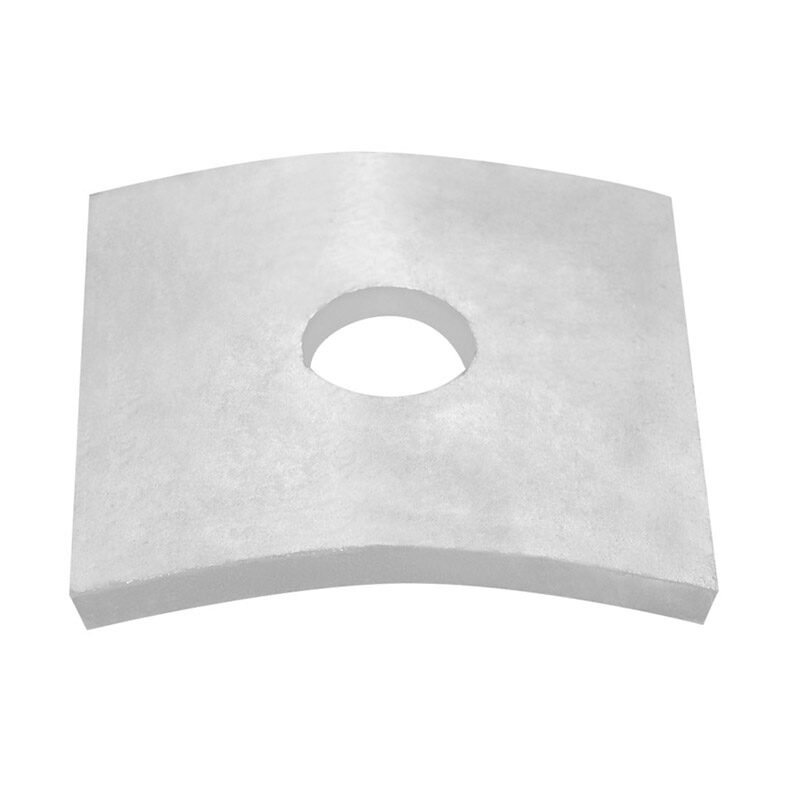

In essence, the stay plate functions as a deadman anchor. It is the subterranean element of a guy assembly. The plate is connected to a stay rod (also called an anchor rod), which extends from the burial depth up towards the ground surface. This rod is then connected to the stay wire, which runs to the pole, counteracting lateral forces from wind, ice, or conductor tension.

The engineering principle is based on passive earth pressure. The large surface area of the stay plate engages a significant volume of soil. When tensile force is applied via the stay wire, the plate attempts to pull upward, but it is resisted by the weight and shear strength of the soil cone above it. This mechanism creates a stable and incredibly strong anchoring point. Without a correctly sized and installed stay plate, the anchor rod would have minimal resistance and would pull out under load, leading to catastrophic pole failure. This makes the component foundational to the structural integrity of overhead lines, especially in areas with poor soil conditions or high-wind exposure.

EPCOM’s High-Quality Manufacturing Process

EPCOM’s stay plates are manufactured from high-strength structural steel, such as Q235 or Q345, selected for its excellent mechanical properties and robustness. However, the most critical stage of our manufacturing process is the corrosion protection. Because these components are designed for direct and permanent burial, they must be able to resist soil-based corrosion for decades.

To achieve this, every EPCOM stay plate undergoes a process of hot-dip galvanization. This involves rigorously cleaning the fabricated steel plate and then immersing it in a bath of molten zinc. This process creates a series of zinc-iron alloy layers, topped by a pure zinc layer, which are metallurgically bonded to the steel. This finish is far superior to paint or plating; it is highly resistant to abrasion during installation and provides sacrificial cathodic protection against corrosion. Our galvanization process complies with rigorous international standards such as ASTM A153, ensuring a maximum service life for your infrastructure.

Key Features of Our Stay Plates

Our anchor plates are engineered to deliver unmatched performance and longevity. Key features include:

- Superior Load Distribution: Engineered square or rectangular shapes designed to maximize soil resistance and anchoring power.

- Extreme Durability: Fabricated from high-tensile structural steel to withstand immense and sustained tensile forces without deformation.

- Maximum Corrosion Protection: Fully hot-dip galvanized finish ensures decades of reliable service, even in aggressive soil environments.

- Versatile Sizing: We offer a wide range of plate dimensions and thicknesses to precisely match specific load requirements and geotechnical conditions.

- Precision Engineering: Features a clean, central hole compatible with all standard stay rod diameters, ensuring a secure and simple connection.

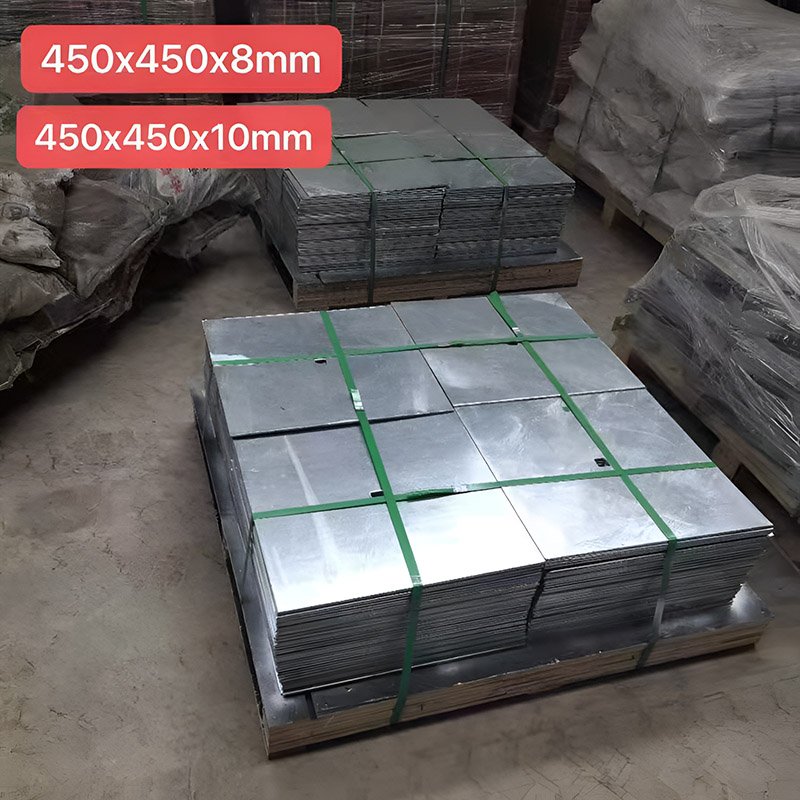

Technical Specifications

EPCOM provides a comprehensive range of anchor plates to suit diverse project needs. While specifications can be customized to meet your exact requirements, the table below outlines our standard product range.

| Parameter | Specification |

|---|---|

| Material | High-Strength Carbon Steel (e.g., Q235, Q345) |

| Finish | Hot-Dip Galvanized (HDG) |

| Galvanization Standard | Conforms to BS-729, ISO 1461, or ASTM A153 |

| Dimensions (Length x Width) | 300x300mm, 400x400mm, 500x500mm, 600x600mm (Custom sizes available) |

| Thickness (T) | 6mm, 8mm, 10mm, 12mm, 16mm |

| Central Hole Diameter | 18mm, 20mm, 22mm, 25mm (To suit M16 to M24 stay rods) |

| Features | Flat square or rectangular plate with central hole. (Optional: Ribbed for reinforcement) |

Applications and Installation of Stay Plate

Stay plates are indispensable in any project involving guyed structures. Common applications include:

- Electrical power distribution and transmission lines.

- Telecommunication masts and mobile network towers.

- Utility poles at line terminations or sharp angles.

- Antenna, radio, and microwave towers.

Proper installation is critical for performance. The stay plate is typically installed at the bottom of an excavated pit or a hole created by an auger. The stay rod is passed through the central hole and secured (often with a square nut). The entire assembly is oriented so that the rod aligns with the angle of the stay wire. Finally, the hole must be backfilled with soil and thoroughly compacted, layer by layer, to achieve the required soil density and anchoring strength.

Ensuring Stability with the Right Stay Plate

Selecting the correct anchor plate size is an essential engineering decision. This choice is not arbitrary; it depends on a careful calculation of the maximum expected tensile load from the guy wire, which is influenced by pole height, wind loading, and conductor tension.

Furthermore, the soil’s geotechnical properties are paramount. Poor or loose soil, such as soft clay, sand, or marshland, has a low bearing capacity. In these conditions, a larger stay plate is required to distribute the same load over a wider area, preventing anchor creep or pull-out. EPCOM’s technical team is available to assist you in selecting the appropriate plate size and strength for your project’s specific geotechnical report and load calculations.

Explore Our Related Power Line Hardware

A complete and reliable stay assembly relies on multiple high-quality components working together. As your comprehensive partner, EPCOM provides the full solution for your pole-line hardware needs.

To properly insulate the conductive stay wire, explore our range of durable **Stay Insulators**. These are designed to handle extreme mechanical stress while providing the necessary electrical isolation.

For system safety and grounding, view our reliable **Optical Cable Grounding Wire**. This is essential for protecting your infrastructure and personnel from fault currents and lightning.

Additionally, to ensure secure and efficient conductor connections, our **JBTL Parallel Groove Connectors** offer excellent electrical conductivity and long-term mechanical strength.

Why Choose EPCOM?

EPCOM is not just a supplier; we are a partner in building resilient and long-lasting power and telecommunication networks. Our unwavering commitment to quality, from precise material sourcing to final galvanization, ensures that every stay plate we deliver meets or exceeds rigorous international standards. We understand that the components buried underground are the most difficult to inspect and replace, which is why we build ours to last.

Trust EPCOM for the foundational components that secure your most critical infrastructure. Contact our expert team today to discuss your project requirements, request customization, or to receive a quote for our stay plate solutions.