SYG Terminal Clamp for Secure Electrical Connections

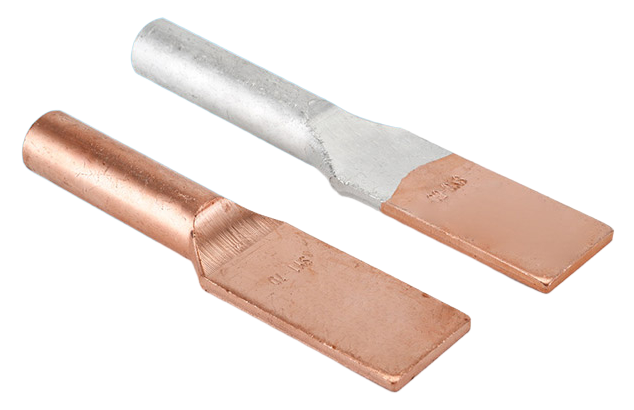

SYG Terminal Clamps are a versatile tool that can be used for a variety of purposes. They are made of high-quality copper and aluminum, and they are easy to use and install. SYG Terminal Clamps are a reliable and cost-effective way to connect wires and cables.

- Securely connects aluminum and copper conductors.

- Manufactured from high-strength, corrosion-resistant aluminum alloy.

- Features a specialized groove geometry to minimize electrical resistance.

- Pre-filled with an oxide-inhibiting compound to prevent moisture and contaminants.

- Complies with or exceeds ANSI C119.4 standards.

Description

The SYG Terminal Clamp from EPCOM is an essential component for creating secure and reliable electrical connections in a variety of demanding applications. Engineered with precision, these terminal clamps are designed to ensure optimal performance and longevity for power distribution systems. They provide a superior solution for connecting and terminating aluminum and copper conductors, effectively preventing issues like galvanic corrosion and ensuring a stable, low-resistance connection throughout the product’s lifespan. Our commitment at EPCOM is to deliver components that not only meet but exceed industry standards, providing our clients with the safety and reliability they require for their critical infrastructure projects.

Unmatched Quality and Design of the SYG Terminal Clamp

At EPCOM, we understand that the integrity of an electrical system depends on the quality of its smallest components. That is why our SYG Terminal Clamps are manufactured using high-strength, corrosion-resistant aluminum alloys. This choice of material ensures durability even in harsh environmental conditions, such as those with high humidity or exposure to industrial pollutants. The design features a specialized groove geometry that provides excellent conductor contact, minimizing electrical resistance and preventing overheating under load. This meticulous engineering makes our clamps a cornerstone for any robust electrical installation.

Core Features of the EPCOM SYG Terminal Clamp

Our terminal clamps are defined by their advanced features, which are tailored to the needs of modern electrical systems. The body of the clamp is forged from a high-conductivity aluminum alloy, which offers an excellent balance of strength and performance. For connecting to copper conductors, our bimetallic models feature a copper-lined groove, a design that is crucial for preventing the galvanic corrosion that can occur when dissimilar metals are in contact. Furthermore, the clamps are treated with an oxide-inhibiting compound that seals the connection from moisture and other contaminants, thereby ensuring a reliable, long-term electrical connection. For securing the assembly, we recommend using our high-quality stainless steel cable ties, which offer exceptional durability and strength.

Applications and Versatility

The versatility of the SYG Terminal Clamp makes it suitable for a wide range of applications. They are most commonly used in overhead and underground distribution networks, connecting tap conductors to main lines. Additionally, they are an ideal choice for substation and switchgear connections, as well as for grounding applications. The robust design allows for use with a broad spectrum of conductor sizes and types, including AAC, AAAC, and ACSR. This flexibility reduces inventory requirements for our clients and simplifies the installation process across different projects. Unlike other connectors such as insulation piercing connectors, which are designed for different use-cases, the terminal clamp provides a bolted connection that is both secure and easily inspectable.

Installation and Tooling for the SYG Terminal Clamp

Proper installation is key to the performance of any electrical connector. The SYG Terminal Clamp is designed for ease of installation. The bolts are engineered to provide the correct clamping force when tightened to the specified torque, ensuring a secure connection without damaging the conductor strands. To facilitate efficient and correct installation, EPCOM offers a range of compatible tools, including the essential stainless steel banding tool for securing related hardware. It is critical that installers follow standardized procedures to prepare the conductor surface and apply the oxide inhibitor correctly, guaranteeing a faultless and durable connection.

Technical Specifications: SYG Terminal Clamp

The following table provides detailed specifications for our range of SYG Terminal Clamps. Please note that EPCOM offers customization options to meet specific project requirements.

| Parameter | Value |

|---|---|

| Model Series | SYG |

| Material | High-Strength Aluminum Alloy (Bimetallic options available) |

| Conductor Range (Main) | 25-240 mm² |

| Conductor Range (Tap) | 16-120 mm² |

| Hardware | Galvanized Steel / Stainless Steel Bolts, Nuts, and Washers |

| Surface Treatment | Pre-filled with Oxide-Inhibiting Compound |

| Compliance | Meets or exceeds ANSI C119.4 standards |

The EPCOM Advantage in Electrical Connections

Choosing EPCOM means partnering with a company dedicated to quality and innovation. Our SYG Terminal Clamps are a testament to this philosophy. We leverage advanced manufacturing processes and stringent quality control to produce components that our customers can trust. The debate between copper and aluminum conductors is well-known in the industry, and our products are engineered to provide optimal performance with both, especially in bimetallic applications. By managing factors like thermal expansion and corrosion, our clamps ensure system integrity and reduce maintenance costs over the long term. Trust EPCOM for all your electrical connection needs, where we deliver not just products, but complete solutions engineered for excellence and reliability.

Our engineering team continuously works to enhance our product offerings, incorporating feedback from the field and advancements in material science. This process of constant improvement ensures that when you specify an EPCOM SYG Terminal Clamp, you are specifying a product that is at the forefront of connection technology. From initial design to final production, every step is monitored to ensure that we provide a product that is safe, reliable, and easy to install. We invite you to contact our technical sales team to discuss your specific requirements and learn more about how our solutions can benefit your next project.