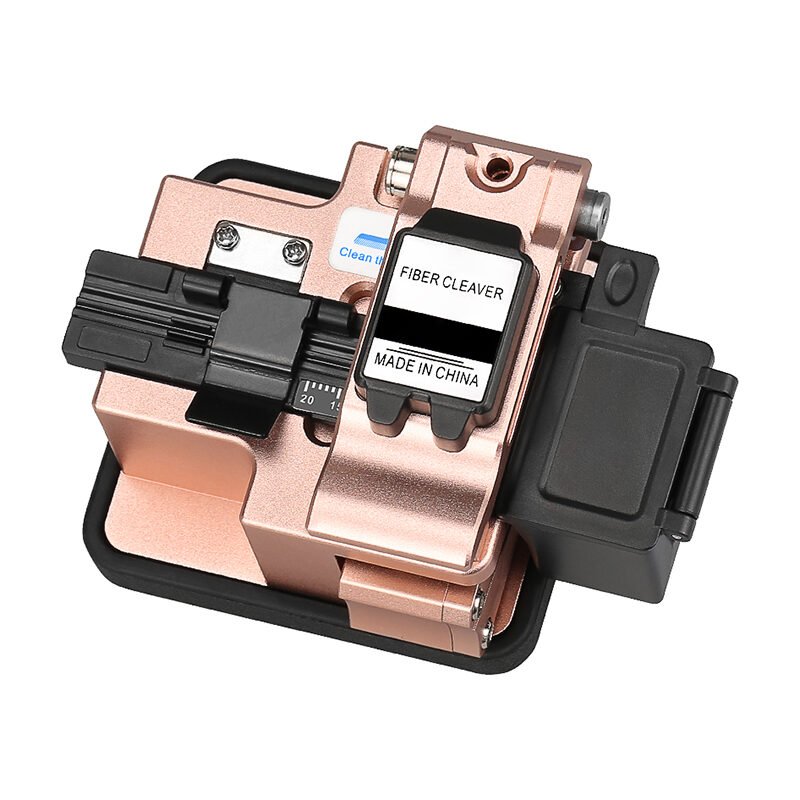

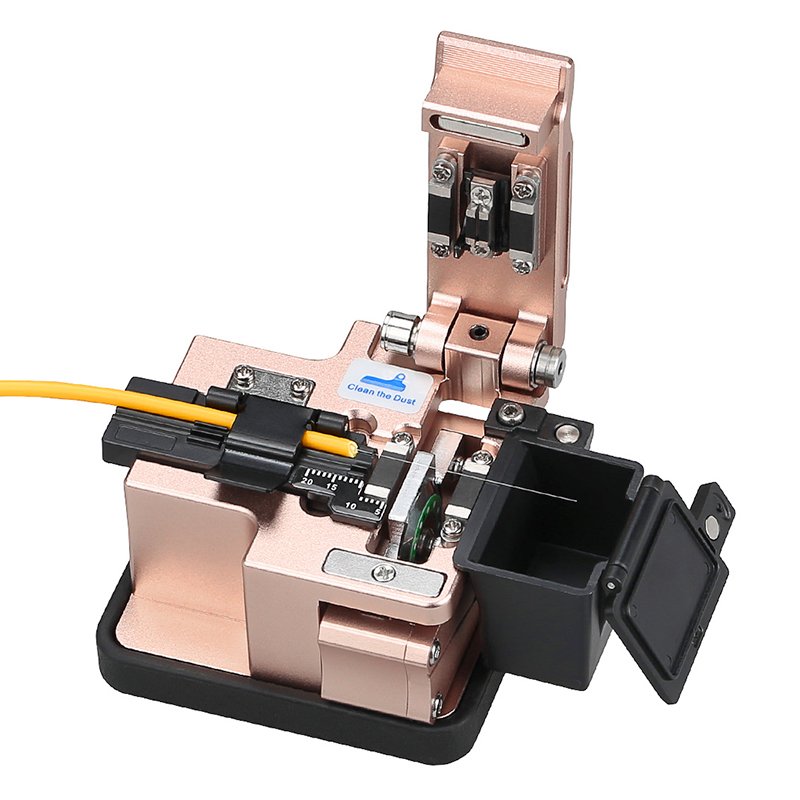

High-Precision Three-in-one Fiber Cleaver

The Fiber Cleaver is a machine used for cutting optical fibers. It is designed to cut optical fibers with high precision and accuracy. It is a versatile tool that can be used for a variety of tasks, including cutting optical fibers, repairing optical fibers, and testing optical fibers.

- High-precision tungsten steel alloy blade for clean, flat fiber end-faces.

- Versatile **Three-in-one** fiber holder for bare fiber, pigtails, and patch cords.

- Blade service life of up to 48,000 cleaves.

- Automatic blade rotation system for consistent cutting quality.

- Built-in fiber scrap collector for a safer work environment.

Description

The Three-in-one Fiber Cleaver from EPCOM is an essential tool engineered for superior performance in fiber optic network installations and maintenance. This device delivers unmatched precision, ensuring clean, flat, and perpendicular end-faces on optical fibers, which is critical for minimizing signal loss and maximizing network efficiency. Its robust and ergonomic design provides technicians with a reliable instrument for fieldwork in various environments, from data centers to FTTH rollouts. By integrating multiple functions into a single unit, this cleaver simplifies the technician’s toolkit, enhances workflow, and ultimately reduces operational time and costs. It is the cornerstone of any professional fiber optic toolkit, enabling flawless fusion splicing and connector termination.

Key Features of the Three-in-one Fiber Cleaver

Our cleaver is designed with the user in mind, combining functionality with durability. The core strength lies in its versatile 3-in-1 fiber holder, which is compatible with bare fiber (250μm), pigtails (900μm), and fiber patch cords (2.5mm), eliminating the need to switch holders for different cable types. This adaptability makes it an incredibly efficient tool for technicians working on diverse projects. The blade itself is crafted from high-density, tungsten steel alloy, offering an exceptional service life of up to 48,000 cleaves. Furthermore, the automatic blade rotation system ensures that a fresh, sharp cutting surface is used for each cleave, maintaining consistency and quality over the long term. A built-in fiber scrap collector safely stores hazardous fiber shards, promoting a safer work environment.

Wide-Ranging Applications for the Fiber Cleaver

The versatility of this high-precision tool makes it indispensable across a spectrum of applications. In the telecommunications sector, it is vital for constructing and maintaining long-haul networks and metropolitan area networks. For enterprise-level projects, data center technicians rely on it for precise connections that support high-speed data transmission. Moreover, it is a key component in Fiber-to-the-Home (FTTH) deployments, enabling the rapid and reliable installation of residential and commercial fiber connections. The consistent performance of the Three-in-one Fiber Cleaver ensures optimal signal integrity, which is fundamental for applications like high-definition video streaming, online gaming, and other bandwidth-intensive services. Its reliability directly contributes to the quality of the end-user experience.

Product Specifications

The technical specifications below detail the performance and physical characteristics of our cleaver. EPCOM is committed to transparency and quality, ensuring that our products meet the highest industry standards.

| Parameter | Value |

|---|---|

| Cutting angle | 0.5° about |

| Cutting length | 9-16mm (0.25) / 10-16mm (0.25) |

| Fiber diameter type | 125μm |

| Application fiber type | 0.25&0.9mm |

| Blade service life | About 48000 times |

| Optimal operating temperature | -40~80°C |

| Optimal storage temperature | -40~80°C |

| Dimension | 90mm(W) X 62mm(D) X 60mm(H) |

| Weight | About 339g |

Enhancing Your Toolkit with the Right Accessories

Achieving a perfect fiber optic connection requires more than just a great cleave. It is crucial to maintain a clean work environment and verify the integrity of your network. Before making a connection, always ensure the fiber end-face is pristine. For this, we highly recommend using a Fiber Optic Cassette Cleaner, which effectively removes dust, oil, and other contaminants without scratching the surface. Additionally, for creating reliable connections, you will need a high-quality fiber patch cord. After the connection is made, it is best practice to validate its performance. An Optical Fiber Tester will help you measure signal loss and identify any potential issues, ensuring the network meets performance specifications.

Why Choose EPCOM’s Three-in-one Fiber Cleaver?

At EPCOM, we are dedicated to providing high-quality solutions that empower technicians to build the next generation of communication networks. Our Three-in-one Fiber Cleaver is a testament to this commitment. It undergoes rigorous quality control processes to ensure it meets the demanding standards of the fiber optics industry. The compact and lightweight design, combined with its simple, two-step operation, minimizes the potential for human error and maximizes productivity. Investing in this tool means investing in reliability and precision. It is built to withstand the rigors of daily field use while consistently delivering the perfect cleave, every single time. Trust EPCOM to provide the tools you need to get the job done right.