Robust Power Enclosures: Safety Solutions

Power Enclosures are essential components in nearly every electrical system, providing critical protection for sensitive equipment and ensuring the safety of personnel. These enclosures, also known as electrical cabinets or boxes, house a variety of electrical and electronic components, shielding them from environmental factors, accidental contact, and unauthorized access. As technology advances and electrical systems become more complex, the demand for high-quality, durable, and application-specific power enclosures continues to grow. Consequently, understanding their features, types, and applications is paramount for engineers, technicians, and project managers alike. EPCOM is dedicated to providing robust solutions that meet these evolving needs, safeguarding your valuable assets and ensuring operational integrity.

Understanding the Core Role of Power Enclosures

The fundamental purpose of power enclosures extends beyond simple housing. They are integral to system reliability, longevity, and safety. Without adequate protection, electrical components are vulnerable to dust, moisture, corrosive substances, extreme temperatures, and physical impact, all of which can lead to malfunctions, premature failure, and hazardous conditions. Therefore, selecting the correct type of power enclosure is a critical decision in the design and implementation of any electrical installation.

What Defines Modern Power Enclosures?

Modern power enclosures are sophisticated products engineered to meet stringent standards and diverse operational requirements. They are characterized by several key attributes, including their material composition, protection ratings (such as NEMA and IP), thermal management capabilities, security features, and ease of access for maintenance. Furthermore, today’s enclosures often need to accommodate advanced electronics, communication interfaces, and customized internal layouts. The design philosophy emphasizes not just protection, but also functionality and adaptability to specific industrial, commercial, or residential contexts. For instance, an industrial power enclosure might prioritize ruggedness and resistance to harsh chemicals, while a telecommunications enclosure might focus on thermal management and modularity.

The Critical Importance of Secure Power Enclosures in Today’s Infrastructure

In an increasingly connected world, the security of electrical and electronic systems is paramount. Secure power enclosures play a vital role in protecting critical infrastructure from tampering, vandalism, and environmental threats. This is particularly important in sectors such as energy distribution, telecommunications, transportation, and public utilities. Features like robust locking mechanisms, reinforced construction, and ingress protection are crucial. Moreover, ensuring that these enclosures prevent unauthorized access helps maintain operational continuity and protects sensitive data or control systems housed within. The reliability of countless services often depends on the integrity of these protective housings.

Key Terminology Associated with Power Enclosures

Navigating the world of power enclosures involves understanding some specific terminology. “Ingress Protection (IP) ratings,” for example, define the level of protection against solids and liquids. “NEMA ratings,” commonly used in North America, specify protection against various environmental conditions like water, dust, oil, and corrosive agents. Other terms include “thermal management,” referring to the enclosure’s ability to dissipate heat; “form factor,” describing its size and shape; and “material specifications,” detailing the type of metal or plastic used. Familiarity with these terms helps in making informed decisions when selecting the appropriate electrical power enclosures for any given application.

Diverse Types of Power Enclosures and Their Applications

Power enclosures come in a vast array of types, each designed to suit specific environments and operational demands. The selection process hinges on understanding these different categories and matching them to the application’s unique requirements. From general-purpose boxes to highly specialized, environmentally sealed units, the right choice ensures optimal performance and longevity of the housed components.

General Purpose Power Enclosures

General purpose power enclosures are designed for indoor use in environments where unusual service conditions do not exist. They primarily offer protection against accidental contact with live parts and may provide some defense against falling dirt. These are often found in commercial buildings, light industrial settings, and residential applications where the primary concern is basic safety and component organization. While not intended for harsh environments, they serve a crucial role in a wide range of standard electrical installations.

Weatherproof and Outdoor Power Enclosures

When electrical equipment needs to be installed outdoors or in environments exposed to the elements, weatherproof and outdoor power enclosures are indispensable. These enclosures are specifically designed to resist rain, sleet, snow, windblown dust, and sometimes even temporary submersion. Their construction often involves robust materials like stainless steel, aluminum, or UV-resistant polycarbonate. Effective sealing, corrosion resistance, and appropriate NEMA or IP ratings are hallmarks of reliable outdoor power enclosures, making them suitable for applications like telecommunications, renewable energy installations, and external industrial controls.

Industrial Control Panel Power Enclosures

Industrial settings often present demanding conditions, including exposure to dust, oil, coolants, and vibrations. Industrial control panel power enclosures are built to withstand these rigors while securely housing motor starters, PLCs, drives, and other control components. They typically feature robust construction, secure latching systems, and may incorporate provisions for cooling or heating to maintain optimal operating temperatures for the enclosed electronics. The safety and efficiency of manufacturing processes heavily rely on the integrity of these specialized power enclosures.

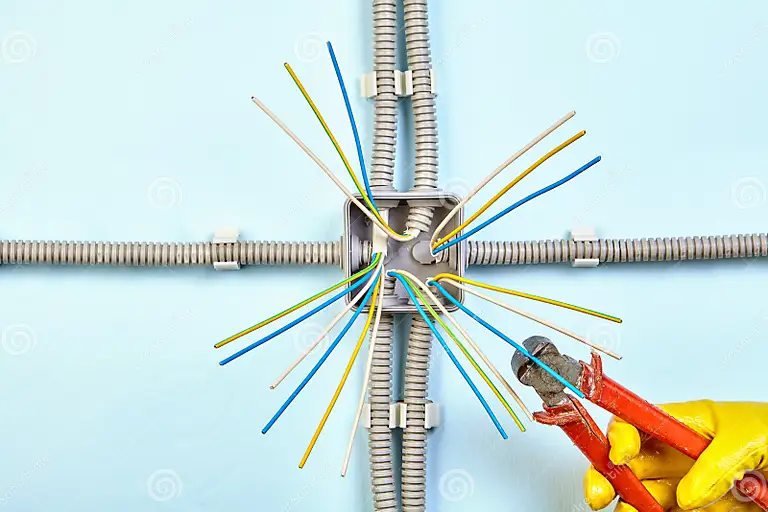

Junction Box Power Enclosures: A Closer Look

Junction boxes are a common type of power enclosure, primarily used to house wiring connections. They protect these connections from environmental factors and prevent accidental contact. A critical subset of these is the waterproof junction box, designed for wet or damp locations. EPCOM offers high-quality Waterproof Junction Box solutions that provide excellent protection against moisture ingress, making them ideal for outdoor installations, washdown areas, or any application where water exposure is a concern. These junction box power enclosures ensure the safety and reliability of electrical circuits in challenging environments.

Specialized Power Enclosures for Unique Environments

Beyond the common types, there are numerous specialized power enclosures designed for unique or extreme environments. These include hazardous location enclosures (for explosive atmospheres), EMI/RFI shielded enclosures (to prevent electromagnetic interference), and hygienic enclosures (for food processing or pharmaceutical applications). These highly specialized units often require specific certifications and are engineered with materials and design features tailored to their intended use, demonstrating the versatility and adaptability of power enclosure technology.

Key Considerations When Selecting Power Enclosures

Choosing the right power enclosure is a critical step that impacts the safety, reliability, and lifespan of your electrical and electronic equipment. A systematic approach, considering various factors, will lead to an optimal selection. It’s not merely about finding a box; it’s about finding a protective environment tailored to the components and the operational setting.

Material Matters: Choosing the Right Build for Your Power Enclosures

The material of a power enclosure significantly influences its durability, weight, cost, and resistance to environmental factors. Common choices include metals like steel, stainless steel, and aluminum, and non-metallic options such as polycarbonate and fiberglass.

Metal Power Enclosures (Steel, Stainless Steel, Aluminum)

Steel enclosures, often powder-coated for corrosion resistance, are a common and cost-effective choice for general-purpose indoor applications. Stainless steel offers superior corrosion resistance, making it ideal for harsh industrial environments, food processing, and outdoor installations, particularly in marine or chemical-laden atmospheres. Aluminum power enclosures provide a good balance of strength, light weight, and natural corrosion resistance, often favored for outdoor and portable applications. Understanding the properties of sheet metal is crucial when evaluating these options.

Non-Metallic Power Enclosures (Polycarbonate, Fiberglass)

Non-metallic power enclosures, such as those made from polycarbonate or fiberglass, offer excellent resistance to corrosion and chemicals, are lightweight, and can be more cost-effective for certain applications. Polycarbonate is known for its high impact strength and UV stability, making it suitable for outdoor use. Fiberglass enclosures are extremely durable and can withstand harsh chemical exposures and wide temperature ranges. These materials also offer good electrical insulation properties.

Understanding NEMA and IP Ratings for Power Enclosures

NEMA (National Electrical Manufacturers Association) and IP (Ingress Protection) ratings are standards that define the level of protection an enclosure provides against environmental factors. Understanding these ratings is crucial for selecting an enclosure that will adequately protect its contents. NEMA ratings, predominantly used in North America, classify enclosures based on their ability to protect against dust, dirt, water, oil, and coolants. For example, a NEMA 1 enclosure is for general indoor use, while a NEMA 4X enclosure offers protection against corrosion and hose-directed water. You can find more information from NEMA directly. IP ratings, an international standard from the IEC, use a two-digit system: the first digit indicates protection against solid objects (dust), and the second against liquids (water). For instance, an IP67 rated enclosure is dust-tight and can withstand temporary immersion in water. Choosing the correct NEMA or IP rated power enclosures ensures equipment survivability.

Security Features for Protecting Sensitive Equipment within Power Enclosures

Security is a major concern, especially for outdoor power enclosures or those housing critical control systems. Features to look for include robust locking mechanisms (key locks, pad-lockable handles, multi-point latching systems), concealed hinges, and reinforced construction to prevent unauthorized access, vandalism, or theft. Some advanced power enclosures may also incorporate intrusion detection sensors. The level of security required will depend on the value and sensitivity of the enclosed equipment and the installation environment.

Thermal Management: Ventilation and Cooling for Power Enclosures

Electronic components generate heat, and excessive temperatures can lead to performance degradation and premature failure. Effective thermal management within power enclosures is therefore essential. This can be achieved through various means, including passive ventilation (louvers, vents), forced air cooling (fans and filters), heat exchangers, or even air conditioning units for high heat load applications. The choice of thermal management solution depends on the amount of heat generated by the enclosed equipment, the ambient temperature, and the enclosure’s NEMA/IP rating, as ventilation can sometimes compromise ingress protection if not designed properly.

Size, Mounting, and Accessibility of Power Enclosures

The physical dimensions of the power enclosure must be adequate to house all components comfortably, with sufficient space for wiring, future expansion, and airflow. Consider the overall footprint and depth. Mounting options are also important – enclosures can be wall-mounted, pole-mounted, floor-standing, or free-standing. The chosen mounting method should be appropriate for the location and ensure stability. Finally, accessibility for installation, maintenance, and troubleshooting is key. Features like removable doors, gland plates for cable entry, and well-organized internal layouts facilitate easier servicing of the equipment within the power enclosures.

EPCOM’s Premier Solutions for Electrical Needs

At EPCOM, we understand the critical role that reliable electrical components play in the safety and efficiency of any project. We are committed to providing high-quality products that meet diverse application requirements, from basic wiring accessories to specialized distribution systems. Our focus is on delivering solutions that offer durability, performance, and peace of mind.

Introducing EPCOM: Your Partner in Reliable Electrical Components

EPCOM stands as a trusted provider of a wide range of electrical solutions, including innovative power enclosures and essential accessories. Our mission is to empower our clients with products that not only meet industry standards but also exceed expectations in terms of quality and functionality. We believe in building long-term partnerships by offering dependable products and responsive customer support. Whether you are working on a small residential project or a large-scale industrial installation, EPCOM has the components to help you succeed.

Essential Wiring Accessories: American Standard Switches and Sockets

Proper wiring is fundamental to any electrical system, and the quality of switches and sockets directly impacts safety and usability. EPCOM offers a comprehensive range of American Standard Switch and Socket products designed for reliability and ease of installation. These components are manufactured to meet rigorous quality standards, ensuring safe and consistent performance. While not power enclosures themselves, these accessories are often used in conjunction with or are wired to systems protected by enclosures, forming an integral part of the overall electrical infrastructure.

Robust Protection with EPCOM’s Waterproof Junction Box

As previously highlighted, protecting electrical connections in wet or demanding environments is crucial. EPCOM’s Waterproof Junction Box series offers superior protection against moisture, dust, and impact. These junction box power enclosures are engineered for durability, featuring high-quality seals and robust construction. They are an ideal choice for outdoor lighting, marine applications, agricultural settings, and industrial washdown areas, ensuring that your wiring remains secure and operational even in challenging conditions. Choosing EPCOM’s waterproof solutions means investing in long-term reliability.

Efficient Power Distribution: The Grid-Connected Distribution Box by EPCOM

For applications requiring organized and safe distribution of power, EPCOM provides solutions like the Grid-Connected Distribution Box. These units are a specialized type of power enclosure designed to house circuit breakers, terminals, and other distribution components. They facilitate the safe and efficient management of electrical power from a source (like the grid or a generator) to various loads. Such distribution boxes are essential in residential, commercial, and industrial settings for ensuring that power is distributed in a controlled and protected manner, often forming a key part of a larger system of power enclosures and electrical infrastructure.

Why Custom Power Enclosures from EPCOM Make a Difference

While standard enclosures meet many needs, some projects require tailored solutions. EPCOM understands that off-the-shelf products may not always be the perfect fit. We work with clients to provide custom power enclosures designed to specific dimensions, material requirements, internal layouts, and with pre-installed accessories or cutouts. This collaborative approach ensures that you receive an enclosure perfectly suited to your application, optimizing space, functionality, and protection. Custom power enclosures can lead to more efficient installations and better long-term performance.

Installation Best Practices for Power Enclosures

Proper installation is as crucial as selecting the right power enclosure. A correctly installed enclosure ensures optimal protection for the equipment, maintains its specified NEMA/IP rating, and guarantees the safety of personnel. Following best practices during installation will prevent future problems and maximize the enclosure’s lifespan.

Site Assessment and Preparation for Power Enclosure Installation

Before installing any power enclosure, a thorough site assessment is necessary. Consider the environmental conditions (temperature, humidity, exposure to chemicals or dust), available space, and accessibility for future maintenance. The mounting surface must be structurally sound and capable of supporting the weight of the enclosure and its contents. Ensure the location complies with all relevant electrical codes and safety regulations, such as those outlined by OSHA for electrical safety. Preparation might include clearing the area, preparing the mounting surface, and planning cable routes.

Ensuring Secure Mounting and Grounding of Power Enclosures

The power enclosure must be securely mounted according to the manufacturer’s instructions using appropriate hardware. Whether it’s wall-mounted, floor-standing, or pole-mounted, stability is key to preventing damage and ensuring safety. Crucially, proper grounding (earthing) of metallic power enclosures is mandatory to protect against electrical shock hazards. This involves connecting the enclosure to the system’s grounding conductor, providing a safe path for fault currents. Always verify grounding continuity after installation.

Cable Management within Power Enclosures

Effective cable management inside and outside the power enclosure is vital for organization, safety, and performance. Use appropriate cable glands, conduits, or entry ports that maintain the enclosure’s IP rating. Inside, route cables neatly, avoiding sharp bends or stress on connections. Use cable ties, ducting, or DIN rails to organize wiring and components. Good cable management not only improves aesthetics but also facilitates airflow, simplifies troubleshooting, and reduces the risk of accidental disconnections or short circuits within the power enclosures.

Adherence to Electrical Codes and Safety Standards

All installation work involving power enclosures must strictly adhere to local, national, and international electrical codes and safety standards (e.g., NEC, IEC). This includes regulations regarding wiring methods, clearances, grounding, and labeling. Using certified components and having qualified personnel perform the installation are essential steps. Non-compliance can lead to safety hazards, equipment damage, and legal liabilities. Regularly updating knowledge on these standards is important for anyone involved in installing power enclosures.

Maintaining Your Power Enclosures for Longevity

Once installed, power enclosures require periodic maintenance to ensure they continue to provide the necessary protection and function as intended. A proactive maintenance schedule can prevent costly downtime, extend the life of the enclosed equipment, and maintain safety standards. The type and frequency of maintenance will depend on the enclosure type and the operating environment.

Regular Inspection Checklists for Power Enclosures

Implementing a regular inspection checklist is a good practice for maintaining power enclosures. This checklist should include:

- Visual inspection for physical damage (dents, cracks, corrosion).

- Checking the integrity of seals and gaskets around doors and cable entries.

- Verifying that locks and latches are functioning correctly.

- Inspecting for signs of water ingress or condensation.

- Checking for loose connections or signs of overheating on internal components.

- Ensuring vents or filters (if present) are clean and unobstructed.

- Confirming that grounding connections are secure.

Keeping records of these inspections helps track the condition of your power enclosures over time.

Cleaning and Environmental Protection for Outdoor Power Enclosures

Outdoor power enclosures are particularly susceptible to dirt, debris, and biological growth (e.g., mold, algae). Regular cleaning according to the manufacturer’s recommendations is important. Use appropriate cleaning agents that do not damage the enclosure material or its finish. For enclosures in corrosive environments, check for any signs of material degradation and address them promptly. Ensuring drainage holes are clear and that the surrounding area is free from vegetation or obstructions that could trap moisture will enhance the longevity of outdoor power enclosures.

Component Upgrades and Retrofitting within Existing Power Enclosures

Over time, the equipment housed within a power enclosure may need to be upgraded, or new components may need to be added. When retrofitting, it’s crucial to ensure that the modifications do not compromise the enclosure’s integrity or its NEMA/IP rating. This might involve drilling new entry points (which must be properly sealed) or adding new mounting hardware. Always consider the thermal impact of new components and ensure that the enclosure’s cooling capacity is still adequate. If significant changes are made, it’s wise to re-verify the overall safety and compliance of the modified power enclosures.

Comparing Common Power Enclosure Materials

Choosing the right material is fundamental when selecting power enclosures. The table below offers a comparison of common materials used by EPCOM and other manufacturers, highlighting their key characteristics to aid in your decision-making process.

| Material | Corrosion Resistance | Impact Strength | Weight | Typical Applications |

|---|---|---|---|---|

| Painted Carbon Steel | Fair (depends on coating) | Good | Heavy | General indoor industrial |

| Stainless Steel (304/316) | Excellent | Very Good | Heavy | Food & beverage, chemical, marine, outdoor |

| Aluminum | Good | Fair to Good | Light | Outdoor, portable equipment, corrosive environments |

| Polycarbonate | Excellent | Excellent (high impact) | Very Light | Outdoor, corrosive environments, electrical insulation |

| Fiberglass Reinforced Polyester | Excellent | Good | Light | Harsh chemical environments, wide temperature ranges |

The Future of Power Enclosure Technology

The field of power enclosure technology is not static. As industries evolve and new challenges emerge, enclosures are adapting with innovative features, materials, and capabilities. Several trends are shaping the future of how we protect and manage electrical and electronic systems.

Smart Power Enclosures and IoT Integration

The Internet of Things (IoT) is increasingly influencing industrial and commercial applications. Smart power enclosures are emerging, equipped with sensors to monitor internal conditions such as temperature, humidity, and unauthorized access. These enclosures can communicate data wirelessly, allowing for remote monitoring and predictive maintenance. This integration enhances system reliability, reduces the need for manual inspections, and enables quicker responses to potential issues, making power enclosures an active part of a connected infrastructure.

Sustainable Materials and Manufacturing in Power Enclosures

Environmental concerns are driving a shift towards more sustainable practices in manufacturing. For power enclosures, this means exploring the use of recycled materials, developing more energy-efficient manufacturing processes, and designing enclosures for easier disassembly and recycling at the end of their life. The development of bio-based polymers and advanced composites also holds promise for reducing the environmental footprint of future power enclosures without compromising performance or durability.

Enhanced Durability and Resilience in Next-Generation Power Enclosures

As critical infrastructure becomes more reliant on uninterrupted power and control, the demand for even more durable and resilient power enclosures is growing. This includes developing materials and designs that can withstand extreme weather events, higher impact forces, and more aggressive corrosive agents. Advanced coatings, new alloy formulations, and innovative structural designs are contributing to next-generation power enclosures that offer superior protection in the most demanding conditions, ensuring system survivability and operational continuity.

Why Trust EPCOM for Your Power Enclosures and Components?

Choosing a supplier for critical components like power enclosures is a decision that impacts the safety, reliability, and efficiency of your operations. EPCOM is dedicated to being more than just a supplier; we aim to be a trusted partner in your success by offering quality products, expert support, and a commitment to meeting your specific needs.

Commitment to Quality and Durability in EPCOM Products

At EPCOM, quality is not an afterthought; it is a core principle. Our power enclosures and electrical components are manufactured using high-grade materials and undergo rigorous testing to ensure they meet or exceed industry standards. We understand that durability is key to long-term performance, especially in challenging environments. This commitment means that when you choose EPCOM, you are investing in products designed to last, providing reliable protection and operational stability for your valuable equipment.

Expert Support and Custom Solutions for Your Power Enclosure Needs

We recognize that every project has unique requirements. Our team of knowledgeable professionals is available to provide expert advice and support, helping you select the most appropriate standard power enclosures for your application. Furthermore, for specialized needs, EPCOM offers custom design and manufacturing services. We collaborate closely with clients to develop tailored power enclosures that precisely match their specifications, from dimensions and materials to cutouts and pre-installed accessories. This flexibility ensures you get the optimal solution, not just an adequate one.

EPCOM’s Vision for Safe and Efficient Power Management

EPCOM’s vision extends beyond simply selling products. We aim to contribute to safer and more efficient power management across all sectors. By providing robust and reliable power enclosures, including specialized solutions like our Waterproof Junction Box and Grid-Connected Distribution Box, and essential accessories such as American Standard Switches and Sockets, we help our customers protect their investments, ensure personnel safety, and optimize their electrical systems. We are continuously exploring new technologies and innovative designs to enhance our offerings and address the evolving challenges of modern electrical infrastructure.

Exploring Applications: Where Power Enclosures Shine

The versatility of power enclosures means they are found in an astonishingly wide range of applications. Their fundamental role in protecting electrical and electronic equipment makes them indispensable across numerous industries and settings, each with its own set of challenges and requirements for these protective housings.

Power Enclosures in Industrial Automation and Manufacturing

In the demanding environment of industrial automation and manufacturing, power enclosures are critical for protecting sensitive control systems, PLCs, VFDs, and robotic controllers. These settings often involve dust, debris, moisture, chemical exposure, and significant temperature fluctuations. Industrial power enclosures must provide robust physical protection, often with high NEMA/IP ratings, and sometimes require specialized cooling or heating to maintain optimal operating conditions for the electronics within, ensuring uninterrupted production and worker safety.

Telecommunications and Data Centers: The Need for Reliable Power Enclosures

The telecommunications industry and data centers rely heavily on sophisticated electronic equipment that must operate continuously. Power enclosures in these sectors house servers, routers, switches, and power distribution units. Key considerations include thermal management (to dissipate the significant heat generated), security (to protect valuable equipment and data), and organized cable management. Outdoor power enclosures are also widely used for cellular sites and remote communication hubs, requiring weather resistance and often climate control.

Renewable Energy Systems and their Specialized Power Enclosures

The renewable energy sector, including solar and wind power generation, extensively uses power enclosures. In solar installations, combiner boxes (a type of power enclosure) aggregate power from multiple solar panel strings. Inverters and control systems also require robust protection, often in outdoor environments exposed to harsh weather. These specialized power enclosures must be UV resistant, weatherproof, and capable of handling varying temperatures, ensuring the longevity and efficiency of green energy systems.

Commercial Buildings and Infrastructure Utilizing Power Enclosures

Commercial buildings, from office complexes to shopping malls and hospitals, rely on a vast network of electrical systems. Power enclosures are used to house electrical distribution panels, fire alarm controls, security system components, and HVAC controls. These applications typically require enclosures that meet building codes, provide safety for occupants, and blend aesthetically with the surroundings. Ensuring easy access for maintenance while preventing unauthorized tampering is also a key function of power enclosures in these settings.

Residential Uses of Power Enclosures for Safety and Organization

Even in residential settings, power enclosures play a vital role. Circuit breaker panels are the most common example, protecting the home’s electrical wiring. Outdoor junction boxes, weatherproof enclosures for pool pumps or landscape lighting controls, and even small enclosures for smart home hubs contribute to safety and organization. While typically less demanding than industrial applications, residential power enclosures must still provide reliable protection against accidental contact and environmental factors where applicable.

Deep Dive into Power Enclosure Standards and Certifications

Standards and certifications are foundational to ensuring the safety, reliability, and interoperability of power enclosures. They provide a common language for manufacturers and users, defining levels of protection and performance criteria. Understanding these standards is crucial for selecting compliant and appropriate enclosures for any given application.

Navigating NEMA Standards for Power Enclosures in North America

In North America, the National Electrical Manufacturers Association (NEMA) provides a widely recognized system for rating power enclosures. NEMA standards define types of enclosures based on their ability to protect against specific environmental conditions. For example, NEMA 1 is for general indoor use, NEMA 3R for outdoor use protecting against rain and sleet, NEMA 4X for washdown and corrosive environments, and NEMA 12 for indoor industrial use protecting against dust and dripping liquids. Selecting the correct NEMA type is essential for ensuring the longevity of the equipment housed within the power enclosures and personnel safety.

Understanding IEC IP Codes for Global Power Enclosure Protection

The International Electrotechnical Commission (IEC) publishes the IP (Ingress Protection) rating system, which is used internationally (including Europe and Asia) to classify the degree of protection provided by enclosures against the intrusion of solid objects (including dust) and liquids (water). The IP code consists of two digits: the first digit (0-6) indicates protection against solids, and the second digit (0-9) indicates protection against liquids. For example, IP65 means the enclosure is dust-tight and protected against water jets. Many global power enclosures will carry an IP rating.

Other Relevant Certifications for Specialized Power Enclosures (e.g., UL, ATEX)

Beyond NEMA and IP ratings, other certifications may be required for specialized power enclosures. UL (Underwriters Laboratories) certification indicates that an enclosure has been tested to meet specific safety standards, often required in the US and Canada. For power enclosures intended for use in hazardous locations (e.g., where flammable gases or dusts may be present), certifications like ATEX (for Europe) or IECEx (international) are critical. These certifications ensure the enclosure is designed and manufactured to prevent ignition in potentially explosive atmospheres. Always verify the required certifications for your specific application and jurisdiction.

Customization: Tailoring Power Enclosures to Your Specific Needs

While a wide array of standard power enclosures is available, many applications benefit from or outright require customization. Tailoring an enclosure to precise specifications can enhance functionality, optimize space, improve thermal performance, and simplify installation and maintenance. EPCOM is equipped to assist with these unique requirements.

The Benefits of Custom-Designed Power Enclosures

Custom-designed power enclosures offer several advantages over standard off-the-shelf solutions. They can be built to exact dimensional requirements, ensuring a perfect fit for the available space and the components to be housed. Material selection can be optimized for specific environmental challenges. Internal layouts, including mounting panels, DIN rails, and brackets, can be pre-configured to streamline component installation. Furthermore, custom power enclosures can incorporate unique branding elements, specific paint colors, or specialized access and security features, leading to a more integrated and efficient final assembly.

Common Customizations for Power Enclosures: Size, Cutouts, and Finishes

Some of the most common customizations for power enclosures include modifications to size (height, width, depth), the addition of precise cutouts for human-machine interfaces (HMIs), switches, connectors, and cable entry points. Different finishes and paint colors can be specified for aesthetic reasons or to provide additional environmental protection. Other modifications might involve reinforced mounting points, specific types of hinges and latches, or the integration of viewing windows. These tailored adjustments ensure the power enclosures perfectly serve their intended purpose.

Working with EPCOM for Your Custom Power Enclosure Project

EPCOM understands that unique challenges require unique solutions. Our team is experienced in collaborating with clients to develop custom power enclosures that meet their exact needs. From initial concept and design through to manufacturing and delivery, we provide expert guidance and support. We can work from your drawings or help you develop the specifications for your ideal custom power enclosure. By choosing EPCOM for your custom project, you gain a partner committed to delivering a high-quality, purpose-built solution that enhances your system’s performance and reliability.

Addressing Challenges in Power Enclosure Selection and Deployment

Selecting and deploying power enclosures effectively involves navigating several potential challenges. From harsh environmental conditions to thermal management and long-term reliability concerns, a thoughtful approach is needed to ensure the chosen enclosure performs optimally throughout its service life.

Overcoming Environmental Challenges with Robust Power Enclosures

Environmental factors such as extreme temperatures, humidity, corrosive atmospheres, dust, and water ingress pose significant threats to electrical equipment. Choosing robust power enclosures with appropriate material selection (e.g., stainless steel, GRP) and high NEMA/IP ratings is the first line of defense. For instance, in marine environments or chemical plants, power enclosures made from 316 stainless steel or specialized polymers offer superior corrosion resistance. Proper sealing and gasketing are critical to maintaining the integrity of these protective power enclosures.

Managing Heat Dissipation in High-Density Power Enclosures

As electronic components become more powerful and compact, managing heat dissipation within power enclosures becomes increasingly critical. High-density installations can generate significant thermal loads, leading to overheating if not addressed. Solutions range from passive ventilation and strategically placed vents to active cooling methods like fans, heat exchangers, or even enclosure air conditioners. Thermal modeling and careful planning are essential when designing or selecting power enclosures for high-density applications to ensure reliable operation of the sensitive electronics inside.

Ensuring Long-Term Reliability and Reducing Maintenance for Power Enclosures

The goal for any power enclosure is long-term reliability with minimal maintenance. This is achieved through careful initial selection, proper installation, and proactive, albeit ideally infrequent, maintenance. Choosing high-quality materials, durable finishes, and robust hardware (hinges, latches) contributes to longevity. Designing for ease of access can simplify inspections and any necessary service. While some environments necessitate more frequent checks, a well-chosen and correctly installed power enclosure should provide years of trouble-free service, safeguarding the critical systems within.

For all your power enclosure requirements and associated electrical components, trust EPCOM to deliver quality, reliability, and expert support. We are committed to helping you find the perfect solutions to protect your investments and ensure operational excellence.