The Essential Role of an Optical Fiber Cleaver

An Optical Fiber Cleaver is one of the most fundamental and indispensable tools in the field of telecommunications. While it may seem like a simple cutting device, its function is incredibly precise and critical for the performance of any fiber optic network. The primary purpose of this tool is not merely to cut a fiber, but to create a perfectly flat, mirror-like end-face that is exactly perpendicular to the fiber’s axis. This precision is the bedrock upon which reliable, high-speed data transmission is built. Without a high-quality cleave, subsequent steps like fusion splicing or connectorization are doomed to fail, leading to significant signal loss, poor network performance, and costly troubleshooting. This article delves deep into the world of the optical fiber cleaver, exploring its mechanics, the different types available, how to select the right one for your needs, and the best practices for its use and maintenance, ensuring your network infrastructure is built on a foundation of precision from the very start.

What Exactly is an Optical Fiber Cleaver?

At its core, an optical fiber cleaver is a specialized mechanical tool designed to perform one task with exceptional accuracy: breaking an optical fiber in a controlled manner. Unlike using a pair of scissors or a simple blade, which would shatter the glass and create an unusable, jagged edge, a cleaver uses a sophisticated process often referred to as the “scribe and break” or “score and snap” method. This technique is meticulously engineered to exploit the physical properties of silica glass, the material from which optical fibers are made. The process ensures that the resulting fiber end-face is smooth and clean, free of defects like chips, cracks, or angled surfaces that would otherwise disrupt the path of light, causing it to scatter or reflect and ultimately degrade the signal.

The Core Function of a High-Precision Optical Fiber Cleaver

The magic of a high-precision optical fiber cleaver lies in its controlled application of stress. The process begins when a very sharp, hard blade, typically made of diamond or tungsten carbide, creates a minuscule scratch or “scribe” on the surface of the fiber’s glass cladding. This scribe is the critical first step, as it introduces a tiny, controlled flaw. Once this flaw is introduced, the tool applies precise tension to the fiber, usually by bending it over an anvil with a specific radius. This tension concentrates stress at the tip of the scribe, causing the flaw to propagate cleanly and evenly across the entire fiber diameter. The result is a break that is almost perfectly flat and perpendicular to the fiber axis, typically with an angle of less than 0.5 degrees. This level of precision is impossible to achieve by hand and is absolutely essential for minimizing signal loss in fiber optic connections.

Why a Simple Knife Isn’t Enough

To understand the importance of a proper cleaving tool, it’s helpful to consider the alternative. Attempting to cut an optical fiber with a standard blade or knife would introduce immense, uncontrolled stress. This results in a shattered or fractured end-face, full of imperfections known as “hackle,” “mist,” and “lips.” These defects act as obstacles for the light signal traveling through the fiber core. When light encounters these jagged surfaces, it scatters in multiple directions, leading to a significant loss of signal strength, a phenomenon known as insertion loss. Furthermore, an angled or imperfect end-face can cause light to reflect backward toward its source, creating back reflection. This reflected signal can destabilize laser light sources and introduce noise into the data stream, corrupting the transmitted information. A professional optical fiber cleaver prevents these issues by ensuring the fiber end-face is as close to a perfect mirror as possible.

The Critical Impact of Cleave Quality on Network Performance

The quality of a fiber cleave has a direct and measurable impact on the health of a communications network. Every connection point, whether it’s a permanent splice or a demountable connector, is a potential point of failure. A poor cleave is often the root cause of these failures. For instance, in fusion splicing, two fiber ends are melted together to form a continuous connection. If the end-faces are not perfectly flat and clean, air bubbles and other imperfections can get trapped in the splice point, creating a weak link that causes high signal loss. Similarly, in a mechanical connector, the two fiber ends are precisely aligned and held in close proximity. A poorly cleaved fiber will have a gap or an angular misalignment, leading to both high insertion loss and high back reflection. In a modern network with dozens or even hundreds of such connections, these small losses accumulate, severely degrading the overall signal quality and limiting the network’s reach and bandwidth.

Exploring the Main Types of Optical Fiber Cleavers

While all optical fiber cleavers operate on the same basic principle, they come in various designs, each suited for different applications, skill levels, and budgets. They can be broadly categorized into two main groups: basic, handheld scribes and high-precision desktop cleavers. The choice between them depends entirely on the requirements of the job, with professional and critical network applications demanding the use of high-precision models.

Pen-Style and Scribe Cleavers (Entry-Level)

Scribe or pen-style cleavers are the simplest and least expensive cleaving tools available. They typically consist of a pen-shaped handle with a small, wedge-shaped diamond or carbide tip. The user manually scratches the fiber surface and then pulls the fiber to break it. While these tools are very portable and cheap, they are highly dependent on the skill and technique of the operator. It is extremely difficult to achieve a consistent, low-angle cleave with a scribe. As a result, they are generally reserved for hobbyist use or for temporary, non-critical connections where performance is not a major concern. For any professional telecommunications work, these tools are considered inadequate.

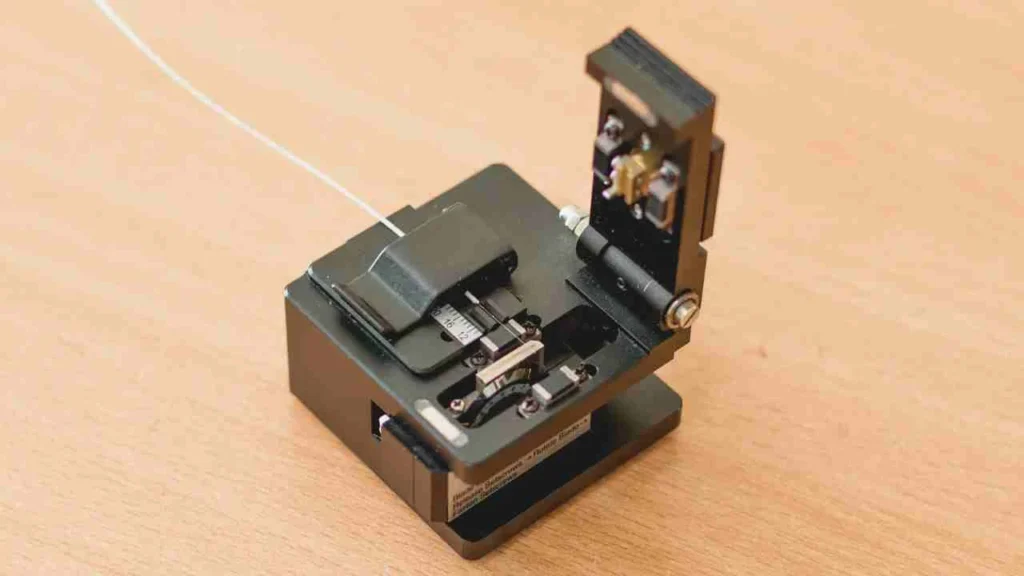

Desktop / High-Precision Optical Fiber Cleavers (Professional Standard)

High-precision desktop cleavers represent the industry standard for all professional fiber optic work. These devices automate the scribing and tensioning process, removing user variability and ensuring a high degree of consistency and accuracy. The fiber is securely placed in a holder within the tool, and the cleaving action is performed by closing a lid or pressing a lever. This single action controls the blade pressure, scribe depth, and tension, resulting in a perfect cleave nearly every time. These cleavers are essential for preparing fibers for fusion splicing and for installing high-performance connectors. They are further divided based on the type of fiber they can handle.

Single Fiber Cleavers

As the name suggests, single fiber cleavers are designed to cleave one fiber at a time. They are the most common type of high-precision cleaver and are used extensively by field technicians for network installation, maintenance, and repair. They feature precision V-grooves and clamps to hold a single 125µm fiber securely in place during the cleaving process. High-quality models, such as those offered by EPCOM, often include features like automatic blade rotation and a scrap collector bin to safely store the dangerous fiber offcuts.

Ribbon Fiber Cleavers

Ribbon fiber cleavers are more specialized tools designed for high-density applications where multiple fibers are bundled together in a ribbon cable. These cleavers can precisely cleave all fibers in a ribbon (which can contain 4, 8, 12, or even more fibers) in a single operation. This capability is crucial in environments like data centers and telecommunications exchanges where speed and efficiency are paramount. Preparing fibers for termination with multi-fiber connectors, which are used in high-performance MPO/MTP Patch Cords, requires the use of these advanced ribbon cleavers to ensure all fiber end-faces are perfectly coplanar.

Key Features to Consider When Choosing an Optical Fiber Cleaver

Selecting the right optical fiber cleaver involves balancing performance, durability, and cost. For professionals who depend on their tools daily, investing in a high-quality device is non-negotiable. Several key features distinguish a superior cleaver from a mediocre one, and understanding them is crucial for making an informed decision.

Cleave Angle and Consistency

The single most important specification of any cleaver is the typical cleave angle it produces. For fusion splicing and high-performance connectors, the cleave angle must be consistently less than 0.5 degrees. A premium cleaver will deliver this performance reliably over thousands of cleaves. Consistency is just as important as the angle itself. A tool that produces a good cleave only intermittently is unreliable and will lead to wasted time and materials. Look for manufacturers’ specifications that guarantee a high success rate of low-angle cleaves.

Blade Life and Material

The cleaver’s blade is a consumable component, but a good one should last for a very long time. Blade life is typically measured in the total number of cleaves it can perform. High-quality blades are often made of tungsten carbide and are mounted on a rotating wheel with multiple positions (e.g., 16 or 24). Each position can perform a set number of cleaves (e.g., 2,000-3,000) before it becomes dull. A blade with 16 positions that each last for 3,000 cleaves will have a total lifespan of 48,000 cleaves. A longer blade life means a lower cost of ownership over time. Some advanced models even feature automatic blade rotation, which advances the blade to a new position after a set number of cleaves, ensuring optimal performance and removing the need for manual tracking.

The Role of an Automated Optical Fiber Cleaver

An automated optical fiber cleaver takes precision and ease of use to the next level. These devices often combine multiple steps into a single action. For example, a “one-step” cleaver might automatically close the clamps, cleave the fiber, and deposit the scrap fiber into a collection bin, all by simply closing the lid. This level of automation significantly reduces the chance of human error, leading to more consistent results, especially for less experienced technicians. It also speeds up the workflow, which can be a major advantage in large-scale fiber deployment projects where hundreds of cleaves need to be performed daily.

The Proper Process for Cleaving Fiber Optic Cable

Using a high-precision optical fiber cleaver is a straightforward process, but it requires a methodical approach to ensure a perfect result every time. Following these steps is crucial for success.

- Preparation: Before you begin, make sure you have all the necessary tools and supplies at hand. This includes fiber optic strippers appropriate for the fiber you are working with, lint-free wipes, and at least 99% pure isopropyl alcohol. Work in a clean, well-lit area.

- Stripping the Fiber: Carefully use the fiber strippers to remove the outer protective layers (buffer and coating) from the end of the fiber, exposing the glass cladding. Be sure to strip the correct length as specified by the instructions for your splicer or connector. Use smooth, steady pressure to avoid nicking or scratching the glass.

- Cleaning the Fiber: This is a critical step. Moisten a lint-free wipe with isopropyl alcohol and gently wipe the stripped fiber from the buffer towards the end, rotating the fiber as you wipe. Use a new, clean section of the wipe for each pass. For a more streamlined and reliable cleaning process, many technicians prefer a dedicated tool like the Fiber Optic Cassette Cleaner, which provides a fresh cleaning surface every time and avoids contamination.

- Placing the Fiber in the Cleaver: Open the lid of the cleaver and carefully place the cleaned fiber into the V-groove. Ensure the fiber is straight and sits flat. Align the edge of the buffer coating with the appropriate length marking on the cleaver’s ruler to achieve the desired cleave length. Close the fiber clamps securely.

- Performing the Cleave: With the fiber secured, close the cleaver lid and press the cleaving lever or button in a single, smooth motion. You may hear a faint “snap” as the fiber is cleaved.

- Inspection: Immediately after cleaving, the fiber end should be inspected. Most modern fusion splicers have a built-in inspection function that can analyze the cleave angle and detect any defects. If a dedicated inspection microscope is available, use it to verify that the end-face is clean, flat, and free of any imperfections before proceeding with splicing or connectorization.

Maintaining Your High-Precision Optical Fiber Cleaver

Like any precision instrument, an optical fiber cleaver requires regular maintenance to continue performing at its best. A well-maintained cleaver will provide reliable service for years, while a neglected one can quickly become a source of problems. The two main aspects of maintenance are cleaning and blade management.

Regular Cleaning Procedures

Dust and debris are the enemies of a good cleave. Small particles of dirt or glass shards can accumulate in the cleaver’s V-grooves and on the rubber clamping pads. This debris can prevent the fiber from sitting straight or being clamped properly, leading to bad cleaves. After each work session, use a can of compressed air to blow out any loose debris. Then, use a cotton swab lightly dampened with isopropyl alcohol to carefully clean the V-grooves and clamping surfaces. Also, remember to regularly empty the fiber scrap collection bin to prevent it from overflowing.

Blade Rotation and Replacement

Over time, the spot on the blade used for scribing will become dull. When you start experiencing a decline in cleave quality, such as consistently high cleave angles or jagged end-faces, it is likely time to rotate the blade to a new, sharp position. The procedure for blade rotation varies between models, so consult your cleaver’s user manual. It typically involves loosening a set screw, turning the blade wheel to the next numbered position, and retightening the screw. Once all positions on the blade have been used, the entire blade must be replaced.

Comparing Optical Fiber Cleaver Technologies

To better understand the options available, the table below provides a comparison between the main types of fiber cleaving tools. It clearly highlights why high-precision cleavers are the standard for any professional application where network performance and reliability are important.

| Feature | Scribe/Pen Cleaver | High-Precision Single Fiber Cleaver | High-Precision Ribbon Cleaver |

|---|---|---|---|

| Cleave Quality | Poor to Fair | Excellent | Excellent |

| Consistency | Very Low | Very High | Very High |

| Typical Angle | > 2 degrees | < 0.5 degrees | < 0.5 degrees |

| Skill Required | Very High | Low | Low |

| Best Application | Hobbyist, Non-critical | Field Installation, Splicing, Repair | Data Centers, High-Density Splicing |

| Cost | Very Low | Moderate | High |

Visualizing Cleave Success Rate

The difference in performance is stark when visualized. The chart below illustrates the typical success rate for achieving a cleave with an angle under 1 degree, which is a common requirement for many applications. It clearly shows why professionals rely exclusively on high-precision tools for their work.

The EPCOM Advantage in Fiber Optic Tools

At EPCOM, we understand that professionals in the telecommunications industry require tools that are not only precise but also rugged, reliable, and easy to use. Our commitment is to provide high-quality equipment that empowers technicians to build and maintain robust fiber optic networks with confidence. Our range of optical fiber cleavers and companion tools is carefully curated to meet the demanding standards of the modern digital infrastructure. We believe that a network is only as strong as its weakest link, which is why we focus on providing tools that ensure every connection point is as close to perfect as possible. From high-precision single fiber cleavers to a full suite of cleaning supplies, EPCOM is your trusted partner for building the networks of tomorrow.

Frequently Asked Questions about Optical Fiber Cleavers

What is the average lifespan of an optical fiber cleaver blade?

The lifespan of a blade is determined by the total number of cleaves it can perform. This is calculated by multiplying the number of blade positions by the number of cleaves per position. A typical high-quality blade might have 16 positions, with each position rated for 3,000 cleaves, resulting in a total life of 48,000 cleaves. This provides a very low cost per cleave and ensures the tool can be used for a long time before the blade needs replacement.

Can I use any optical fiber cleaver with my fusion splicer?

For the most part, yes. Most high-precision cleavers are standalone tools that can be used with any brand of fusion splicer. They produce a cleave of a certain quality and length, which are the important factors. However, some manufacturers sell kits where the cleaver and splicer are designed to work together seamlessly, sometimes by sharing compatible fiber holders that can be moved directly from the cleaver to the splicer, which can improve workflow efficiency.

How often should I clean my optical fiber cleaver?

Best practice dictates that you should perform a quick cleaning after every work session. This involves blowing out any dust with compressed air and emptying the scrap bin. A more thorough cleaning of the V-grooves and clamping pads with isopropyl alcohol should be done daily if the tool is in constant use, or weekly for more moderate use. Keeping the tool clean is the single most effective way to ensure its long-term performance.

Why is my cleave angle suddenly bad?

A sudden decline in cleave quality usually points to one of three issues. First, and most commonly, the cleaver is dirty. Clean the clamping pads and V-grooves thoroughly. Second, the current position on the blade has become dull and needs to be rotated. Third, if the tool has been dropped or subjected to a hard impact, its alignment may have been compromised, in which case it may require professional servicing or recalibration.

What is the purpose of a fiber scrap collector?

The small offcuts of cleaved fiber are extremely sharp and dangerous. They are like tiny glass needles that can easily penetrate the skin and are very difficult to see and remove. A fiber scrap collector is a safety feature that automatically catches and stores these hazardous shards in a secure container, preventing them from falling onto the work surface or floor and ensuring a safe working environment for the technician.

Conclusion: The Foundation of a Reliable Network

The optical fiber cleaver is far more than a simple cutting tool; it is a precision instrument that lays the groundwork for every successful splice and connection in a fiber optic network. The quality of the cleave directly influences signal loss, data integrity, and overall network reliability. Investing in a high-quality, well-maintained cleaver minimizes installation errors, reduces troubleshooting time, and ultimately lowers the total cost of network ownership. Whether you are building a new data center, expanding a telecom network, or repairing a critical link, the journey to a high-performance network begins with a single, perfect cleave. Explore EPCOM’s range of professional-grade fiber optic tools to ensure your network is built on an unshakeable foundation of precision and quality.

In addition to cleavers, remember that a complete fiber optic toolkit includes high-quality cleaning supplies. For high-volume work, a Refillable Cleaner Cassette is an economical and environmentally friendly choice, ensuring you always have a clean surface ready for every fiber end-face.