The Ultimate Guide to a Drop Wire Clamp for FTTH

A Drop Wire Clamp is an essential component in modern telecommunications, acting as the silent guardian of your connectivity. Specifically, in the era of Fiber-to-the-Home (FTTH) networks, the proper management and securing of delicate fiber optic cables are paramount. This is where the drop wire clamp, also known as a drop cable clamp, demonstrates its indispensable value. Consequently, understanding its function, types, and installation is crucial for network reliability. As a leading supplier, EPCOM provides a comprehensive range of solutions designed to meet the rigorous demands of today’s high-speed communication infrastructure. This guide will explore every facet of this critical hardware, ensuring you can make informed decisions for your network deployment.

What Exactly is a Telecom Drop Wire Clamp?

At its core, a telecom drop wire clamp is a small yet powerful device designed to anchor and support a telephone or fiber optic drop wire at the subscriber’s premises. Think of it as the final anchor point that connects the main overhead or underground service line to a building. Furthermore, its primary function is to manage the tension of the drop cable, preventing it from sagging, snapping, or suffering damage due to environmental factors like wind, ice, or rain. Without a reliable drop wire clamp, the integrity of the connection would be compromised, leading to signal loss and service interruptions. Therefore, it is not just a piece of hardware but a critical element for ensuring service continuity and protecting the significant investment made in fiber optic infrastructure.

The Critical Role of the Drop Wire Clamp in FTTH

In FTTH networks, the “drop” portion of the cable is particularly vulnerable. This is the cable that runs from a local distribution point to the end-user’s home or office. Unlike the heavily armored backbone cables, drop cables are lighter and less protected. The role of an FTTH drop wire clamp is therefore magnified.

Firstly, it provides mechanical support. Fiber optic glass is inherently fragile, and excessive tension can cause micro-bends or even fractures, leading to significant signal attenuation. A properly installed fiber optic drop wire clamp secures the cable’s strength member (often aramid yarn or a steel wire), ensuring that all tension is placed on this member, not the delicate optical fibers within.

Secondly, it ensures proper bend radius. The clamp is designed to guide the cable without creating sharp bends that could impede the light signal. Maintaining the minimum bend radius is a fundamental rule in fiber optic installation.

Lastly, it guarantees long-term reliability. By holding the cable securely in place, the clamp prevents the subtle but persistent damage caused by wind-induced vibration and cable movement. In short, this small component is a linchpin for the physical layer security and long-term performance of any FTTH connection.

Types of Drop Wire Clamps Available at EPCOM

Choosing the correct type of drop wire clamp is essential for a successful and durable installation. The selection depends on the cable type, the environmental conditions, and the specific application. EPCOM offers a diverse portfolio to cater to every need. Here, we delve into the most common types and their uses.

P-Type Drop Wire Clamp: Simplicity and Reliability

The P-type drop wire clamp, often called a “wedge clamp,” is one of the most widely used designs for flat telephone and fiber optic cables. Its name comes from its “P” shape. It consists of a perforated shim and a wedge, all housed within a stainless steel or galvanized steel body.

The installation is straightforward: the cable is placed inside the clamp, and as tension is applied to the flexible wire bail, the wedge tightens against the shim, securely gripping the cable. This self-tightening mechanism is highly effective, as the grip strength increases with the load. P-clamps are celebrated for their tool-free installation and are an excellent choice for last-mile FTTH connections involving flat drop cables.

S-Type Drop Wire Clamp: Versatility and Strength

The S-type drop wire clamp is another popular variant, recognized for its fixed, non-removable design and high strength. It is often used in more demanding applications or where a more permanent fixing is desired. The “S” hook design allows for easy attachment to various fixtures, such as pole brackets and building attachments.

This type of aerial drop wire clamp is engineered to provide a secure grip without damaging the cable’s jacket or internal fibers. It’s a testament to how specialized hardware can offer both robustness and protection simultaneously, making it a favorite among telecom technicians for its dependability in diverse field conditions.

Material Matters: Stainless Steel vs. Plastic Drop Wire Clamps

The material of a drop wire clamp directly impacts its lifespan and performance, especially in harsh environments.

- Stainless Steel Drop Wire Clamps: These are the gold standard for durability. Stainless steel offers excellent resistance to corrosion from salt spray (in coastal areas), industrial pollutants, and UV radiation. They provide superior mechanical strength and are ideal for long-term deployments where reliability is non-negotiable. EPCOM’s stainless steel variants ensure that your installation will withstand the test of time.

- Plastic/Nylon Drop Wire Clamps: High-quality, UV-stabilized plastic clamps offer a lightweight and cost-effective alternative. They are dielectric, meaning they do not conduct electricity, which can be an important safety feature in certain situations. While not as robust as their steel counterparts, they are perfectly suitable for many standard residential installations where extreme weather conditions are not a primary concern.

How to Choose the Right Drop Wire Clamp for Your Project

Making the right choice involves a few key considerations. A systematic approach ensures you select a clamp that provides security and longevity.

- Identify Your Cable Type: Is it a flat drop cable, a round drop cable, or a figure-8 cable? The clamp’s design must match the cable’s profile for a secure grip. Using a clamp for a flat cable on a round one will result in slippage and potential damage.

- Assess the Environment: Is the installation near the coast? In an area with high winds or heavy icing? For corrosive or extreme weather environments, a stainless steel drop wire clamp is the superior choice. In milder, inland areas, a high-grade plastic clamp may suffice.

- Consider the Span Length and Tension: For longer spans between the pole and the house, a higher-strength clamp is necessary to handle the increased tension. Always check the clamp’s specified load-bearing capacity.

- Ease of Installation: For large-scale deployments, the speed and ease of installation can significantly impact labor costs. Tool-free designs like the P-type clamp can offer considerable advantages in such scenarios.

Comparison of Drop Wire Clamp Features

To simplify the decision-making process, here is a comparative table of common drop wire clamp types.

| Feature | P-Type Clamp | S-Type Clamp | Plastic Clamp |

|---|---|---|---|

| Primary Cable Type | Flat Cables | Flat or Round Cables | Flat or Round Cables |

| Primary Material | Stainless/Galvanized Steel | Stainless/Galvanized Steel | UV-Stabilized Plastic |

| Installation | Tool-free, wedge system | Requires simple hand tools | Tool-free or simple tools |

| Corrosion Resistance | High to Very High | High to Very High | Excellent (non-metallic) |

| Best For | Rapid FTTH rollouts, flat cables | High-tension applications | Standard residential, coastal areas |

A Step-by-Step Installation Guide for a Drop Wire Clamp

Proper installation is just as important as selecting the right hardware. A poorly installed drop wire clamp can negate the benefits of a high-quality product. Below is a general guide for a typical installation. However, always adhere to local regulations and company-specific practices.

Essential Tools and Preparation for the Job

Before you begin, gather the necessary tools. A typical setup includes a ladder, safety glasses, gloves, and lineman’s pliers. For fiber optic cables, you will also need specialized tools to prepare the cable. This includes stripping the outer jacket and isolating the strength member. For clean and precise cuts of the tough aramid yarn (Kevlar) used as a strength member, nothing beats a pair of dedicated scissors. EPCOM offers high-quality Fibre Optic Kevlar Scissors designed for this exact purpose, ensuring a clean preparation without damaging the fibers.

The Installation Process: Securing the Drop Wire Clamp

- Prepare the Cable: Following the clamp manufacturer’s instructions, strip back a section of the cable’s outer jacket to expose the metallic or non-metallic strength member. Be precise to avoid any nicks on the fibers.

- Insert the Cable: Open the clamp (if it’s a P-type) and insert the drop cable. Ensure it is seated correctly within the clamp’s channel. The strength member should be positioned to take the load.

- Secure the Clamp: For a P-type clamp, insert the wedge and pull the bail wire. The wedge will tighten and lock the cable. For other types, follow the specific fastening mechanism. Give the cable a firm tug to confirm it’s securely gripped.

- Attach to the Support Structure: Loop the clamp’s bail wire over the attachment point, which could be a drive hook, a J-hook, or a pole bracket. Ensure the attachment is secure and rated for the expected load.

- Manage Tension and Drip Loop: Run the cable to the building, maintaining appropriate tension—not too tight, not too loose. Before entering the building, form a “drip loop.” This is a small downward loop in the cable that ensures rainwater drips off at the bottom of the loop rather than running along the cable into the building.

This process is fundamental to the guidelines set by many industry bodies. Organizations like the FTTH Council provide best practices that emphasize the importance of proper physical cable management to ensure the longevity of high-speed telecommunication networks. Adhering to these standards is a mark of professional installation.

Essential Accessories and Complementary Products

A successful installation often relies on more than just the clamp itself. EPCOM provides a full ecosystem of products to ensure a seamless and professional job from start to finish.

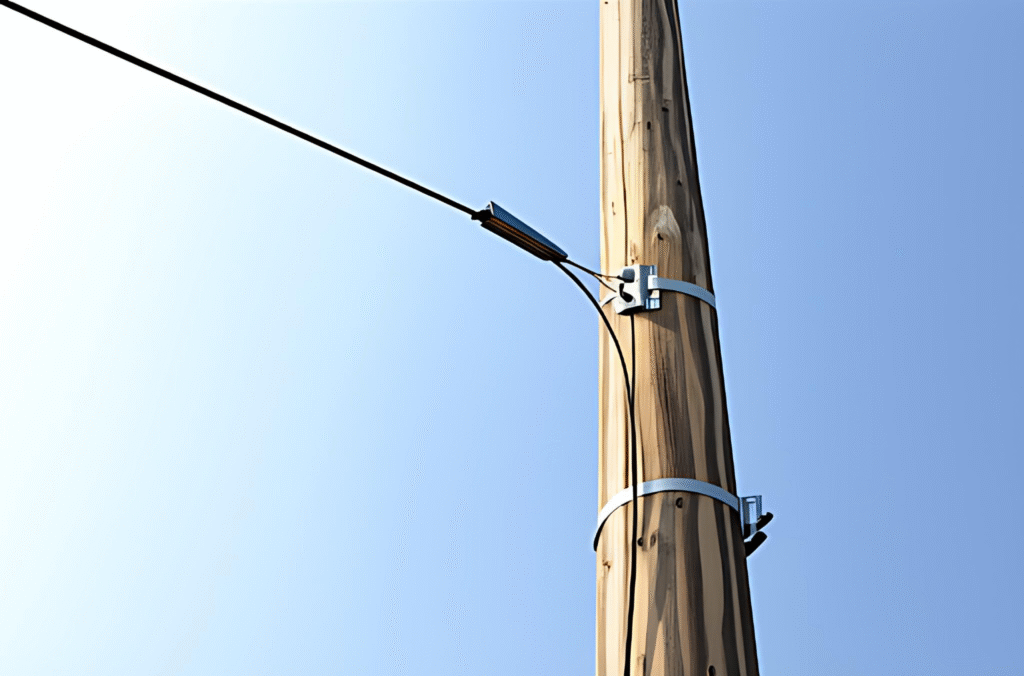

Securing Your Setup with Stainless Steel Straps

In many scenarios, especially in pole-line hardware applications, you need to bundle additional cables or secure conduits. This is where banding tools and straps become invaluable. For ultimate durability and strength, a high-quality stainless steel strap is the ideal solution. It can be used to mount hardware onto poles where drilling is not an option, providing a secure and long-lasting fixture that complements the robustness of your drop wire clamp installation.

The Heart of the Connection: Optical Fiber Fusion Splicer

While the drop wire clamp secures the cable physically, the quality of the signal depends on the connection itself. For creating permanent, low-loss connections between fiber optic cables, fusion splicing is the industry standard. An optical fiber fusion splicer is a sophisticated device that precisely aligns and fuses two fibers together using an electric arc. Investing in a reliable fusion splicer from EPCOM is crucial for any serious FTTH installer, ensuring that the connections are as strong and clear as the infrastructure holding them in place.

Why EPCOM is Your Trusted Partner for Your Drop Wire Clamp Needs

When it comes to telecom hardware, quality and reliability are not just features; they are requirements. EPCOM has established itself as a trusted partner for telecommunication professionals for several key reasons.

- Uncompromising Quality: Every drop wire clamp in our inventory is manufactured to meet or exceed stringent industry standards. We use premium materials, like high-grade stainless steel and UV-stabilized polymers, to ensure our products perform flawlessly in the field for years.

- Comprehensive Selection: We understand that no two jobs are the same. That’s why we offer a vast selection of telecom drop wire clamp models, covering different cable types, materials, and load ratings. Whatever your requirement, EPCOM has a solution.

- Technical Expertise: Our team possesses deep knowledge of telecommunications infrastructure. We don’t just sell products; we provide solutions. We can assist you in selecting the perfect hardware for your specific application, ensuring compatibility and optimal performance.

Frequently Asked Questions (FAQ) about the Drop Wire Clamp

Here are answers to some of the most common questions we receive about this critical component.

1. Can I reuse a drop wire clamp?

While it may be physically possible, it is generally not recommended. The wedge mechanism in many clamps can wear over time, and the material may have been stressed during its first installation. For guaranteed security and to prevent future service calls, it is always best practice to use a new drop wire clamp for every new installation or cable replacement.

2. What is the maximum span for an FTTH drop wire clamp?

This depends entirely on the specific clamp’s load rating and the weight/type of the cable. Typically, specifications will provide a maximum span length under certain tension conditions (e.g., NESC light, medium, or heavy loading zones). Always consult the product’s data sheet and adhere to local utility standards.

3. How do I prevent cable slippage?

Cable slippage is almost always due to using the wrong clamp for the cable type or incorrect installation. Ensure the clamp’s channel matches your cable’s profile (flat vs. round). During installation, make sure the clamp is tightened correctly and that the load is being applied to the cable’s strength member, not just the jacket.

4. Do I need a different drop wire clamp for fiber optic cable than for copper?

Yes, it’s highly advisable. While some may be rated for both, fiber optic drop cables are more sensitive to pressure and bend radius. A dedicated fiber optic drop wire clamp is designed to grip the cable securely without exerting excessive force that could cause signal loss (attenuation). They are engineered to protect the fragile fibers inside.

Conclusion: The Unseen Hero of Connectivity

The drop wire clamp may be a small and often overlooked component in the vast landscape of a telecommunications network, but its role is profoundly important. It is the final, critical link that ensures a stable and secure connection reaches the end-user. From withstanding harsh weather to protecting delicate fiber optic strands, this piece of hardware is a true unseen hero.

By choosing a high-quality drop wire clamp from a trusted supplier like EPCOM and ensuring its correct installation, you are investing in the long-term health and reliability of your network. Browse our extensive collection today or contact our expert team to find the perfect solution for your telecommunication needs.