The Ultimate Guide to Fiber Optic Faceplate Tech

A Fiber Optic Faceplate is a fundamental component in modern telecommunications, serving as the critical termination point that connects end-user equipment to the broader fiber optic network. As data demands surge globally, the need for robust, well-organized, and high-performance network infrastructure has never been more critical. These unassuming wall plates are the linchpin in Fiber to the Home (FTTH), enterprise networks, and data center applications, ensuring that the final link in the data chain is secure, stable, and efficient. At EPCOM, we understand that the quality of your network’s termination point directly impacts overall performance. Therefore, this comprehensive guide will delve deep into the world of the fiber optic faceplate, exploring its types, functionalities, installation processes, and the pivotal role it plays. Furthermore, we will highlight how integrating superior components can future-proof your connectivity, ensuring you are prepared for the next generation of digital innovation. This article will cover everything from the basic definition to advanced applications, providing you with the knowledge to make informed decisions for your networking needs.

What Exactly Is a Fiber Optic Faceplate?

At its core, a fiber optic faceplate, often referred to as a fiber wall plate or fiber optic socket, is a physical interface that provides a secure and organized point for terminating fiber optic cables within a building. Think of it as the final gateway through which light-speed data travels from the main network line to your personal or professional devices. Unlike traditional copper-based systems, which are susceptible to electromagnetic interference and have limited bandwidth, fiber optics transmit data using pulses of light through glass strands. This technology requires precision components to maintain signal integrity. The faceplate houses and protects the delicate fiber connections, typically containing one or more adapter ports (like SC, LC, or ST) that allow for the easy connection of patch cables. Consequently, it not only offers a neat and professional finish to a wall outlet but also safeguards the sensitive fiber ends from dust, damage, and accidental disconnection, which are common causes of network failure. Its design is crucial for maintaining the minimum bend radius of the fiber, preventing signal loss (attenuation) and ensuring optimal performance.

Defining the Modern Fiber Optic Faceplate

The modern Fiber Optic Faceplate has evolved from a simple connection point to a sophisticated component designed for versatility and ease of use. It is engineered to meet the demands of high-density environments like data centers and multi-dwelling units, as well as the aesthetic and functional requirements of residential and office settings. Materials used are typically high-impact, flame-retardant plastics like ABS, ensuring durability and safety. Key characteristics of a modern faceplate include a modular design, allowing for different types and numbers of adapters to be installed. Some feature built-in shutters to protect unused ports from contaminants, while others have angled mounts to reduce physical stress on connected cables and guide them naturally downwards. The primary function remains the same: to provide a seamless and reliable bridge between the network’s backbone cabling and the end-user’s equipment. This function is vital for creating a scalable and easily maintainable network infrastructure that can adapt to future technological advancements.

Core Components of a Fiber Optic Faceplate System

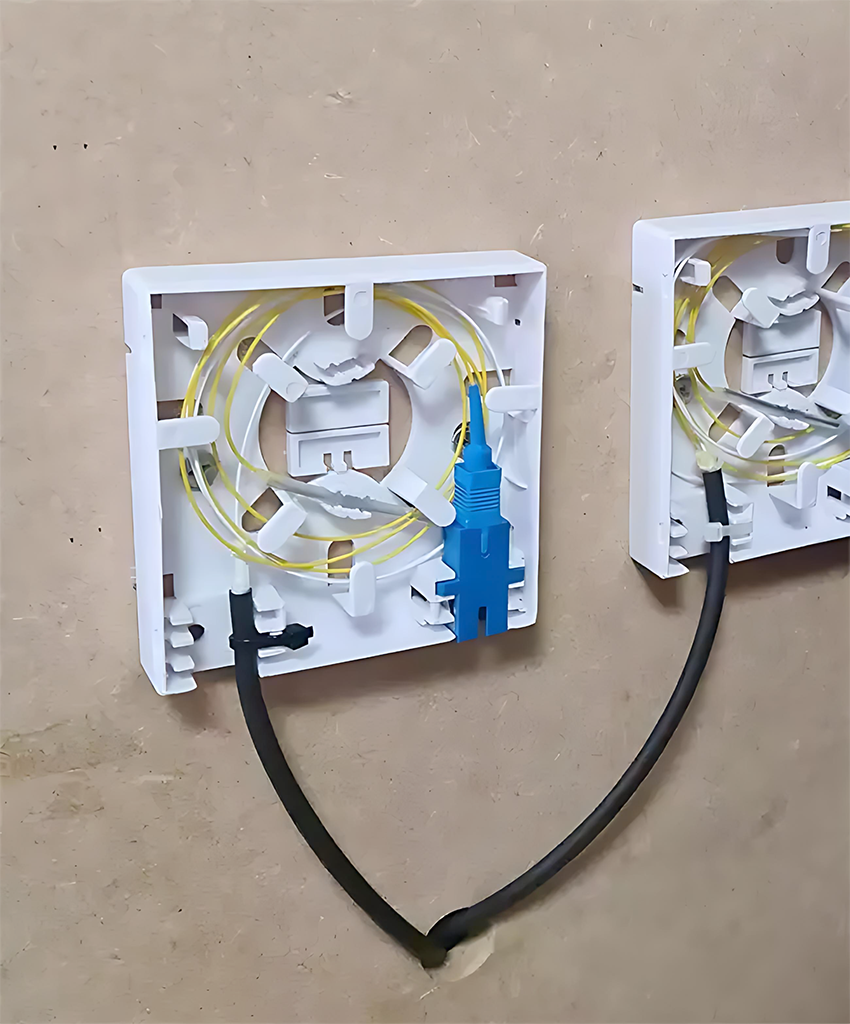

A fiber optic faceplate is part of a larger termination system, and its effectiveness depends on the quality of its surrounding components. The faceplate itself is the housing, but inside, several key parts work in unison. The most critical are the fiber optic adapters (or couplers), which precisely align the microscopic glass cores of two fiber optic connectors, enabling the light signal to pass with minimal loss. These adapters are specific to connector types, such as SC, LC, or ST. Behind the plate, there’s often a small area for slack management, allowing for a small coil of fiber to be stored safely without violating its bend radius. This slack is essential for future repairs or re-terminations. In many FTTH applications, a pigtail—a short fiber cable with a connector on one end and bare fiber on the other—is spliced to the incoming drop cable and then plugged into the back of the adapter in the faceplate. Understanding how these components interact is key to appreciating the faceplate’s role in the network’s physical layer.

The Critical Role of a High-Quality Fiber Optic Faceplate

Investing in a high-quality Fiber Optic Faceplate is not merely about aesthetics; it is a strategic decision that directly impacts network reliability, performance, and long-term operational costs. A well-designed faceplate ensures that every connection is secure and protected, minimizing the risk of signal degradation or complete failure. In a world where consistent, high-speed internet is no longer a luxury but a necessity for business operations, remote work, education, and entertainment, the stability of the physical connection point cannot be overlooked. A substandard faceplate can lead to loose connections, dust ingress, and physical damage to the fiber connectors, resulting in intermittent service, costly troubleshooting, and frustrated users. At EPCOM, we emphasize quality because we know that the physical layer is the foundation upon which the entire network’s performance is built. Therefore, a durable and well-engineered faceplate provides peace of mind and ensures that the immense potential of the fiber optic backbone is fully realized at the user’s end.

A Superior Fiber Optic Faceplate Ensures Signal Integrity

Signal integrity is the holy grail of data transmission. In fiber optics, this means preserving the strength and purity of the light signal as it travels from its source to its destination. A superior Fiber Optic Faceplate plays a crucial role in this by providing a stable and precise housing for the adapters. Precise alignment is paramount; even a microscopic misalignment between two fiber cores can cause significant insertion loss (a weakening of the signal) and back reflection (signal bouncing back towards the source), which can corrupt data. High-quality faceplates are manufactured with tight tolerances to ensure that adapters fit securely, preventing any wiggle or movement that could disrupt this alignment. Furthermore, by protecting the connector end-faces from contaminants like dust and oil, which can obstruct the light path, the faceplate acts as a guardian of signal purity. This meticulous attention to detail at the termination point is essential for maintaining the high bandwidth and low latency that fiber optics promise.

Streamlining Network Management with the Right Faceplate

Effective network management extends to the physical layer. An organized and accessible termination point simplifies installation, maintenance, and troubleshooting. The right fiber optic faceplate contributes significantly to this by providing clear labeling capabilities and easy access to connection ports. In a large-scale deployment, such as an office building or a data center, clearly marked faceplates help technicians quickly identify circuits, reducing downtime during moves, adds, and changes. The design of the faceplate can also impact the ease of installation. Features like ample room for cable management behind the plate, snap-in adapter mechanisms, and robust mounting hardware can save valuable time for installers. For network administrators, a standardized, high-quality faceplate across the entire infrastructure means predictable performance and simplified inventory management. This streamlined approach to the physical termination points is a cornerstone of an efficient and resilient network.

Exploring Different Types of Fiber Optic Faceplates

The market offers a wide array of Fiber Optic Faceplate designs, each tailored to specific applications and environments. The choice of faceplate depends on several factors, including the number of required connections, the type of connectors being used, the installation environment (residential, commercial, or industrial), and aesthetic considerations. For instance, a simple single-port faceplate might be sufficient for a standard home internet connection, while a multi-port, high-density plate is necessary for an office workstation area that requires multiple data and voice connections. EPCOM offers a diverse portfolio to meet these varying needs, from compact wall sockets to versatile multi-port faceplates. Understanding the differences between these types is crucial for network designers and installers to select the optimal solution that balances functionality, scalability, and cost-effectiveness for any given project.

Fiber Optic Faceplate Features at a Glance

To help you choose the right product, we’ve created a table that outlines the key features of different types of faceplates available at EPCOM. This comparison will assist in matching your specific requirements with the best-suited solution.

| Faceplate Type | Port Capacity | Common Connector Types | Ideal Application |

|---|---|---|---|

| 1 Port Fiber Optic Faceplate | Single Port | SC, LC | Residential FTTH, Single Workstation |

| 2 Cores Wall Mount Faceplate | Dual Port | SC, LC, ST | Offices, Multi-device Homes, Small Businesses |

| 4 Cores Fiber Optic Faceplate | Quad Port | SC, LC | Data Centers, Enterprise Networks, High-Density Areas |

| Fiber Optic Wall Socket | 1-2 Ports | SC, LC | End Termination in Villas and Residential Buildings |

Wall Mount Fiber Optic Faceplate Solutions

The most common type is the wall mount Fiber Optic Faceplate. These are designed to be installed flush-mount into a standard electrical box or surface-mount directly onto a wall. Their design prioritizes ease of installation and a clean, unobtrusive appearance. At EPCOM, our wall mount solutions, such as the 2 Cores Wall Mount Face Plate, are engineered with high-quality ABS material for durability. They often include features like a built-in fiber management spool to safely store excess fiber and a hinged or snap-on cover for easy access. These faceplates are the workhorses of FTTH and enterprise network deployments, providing a reliable and professional-looking termination point in living rooms, offices, and communication closets.

Angled vs. Flat Fiber Optic Faceplate Designs

Faceplates come in both flat and angled configurations. A flat faceplate is the traditional design, with the adapter sitting parallel to the wall surface. While perfectly functional, this design can sometimes cause patch cords to protrude awkwardly from the wall, making them vulnerable to being snagged or bent too sharply. An angled Fiber Optic Faceplate, by contrast, positions the adapter at a 45-degree angle. This directs the patch cord downwards, reducing its profile and minimizing stress on the cable and connector. This design is particularly advantageous in high-traffic areas or behind furniture, where space is tight and protecting the connection is paramount. The choice between the two often comes down to the specific installation environment and cable routing plan.

A Step-by-Step Guide to Fiber Optic Faceplate Installation

Proper installation of a Fiber Optic Faceplate is critical to achieving optimal network performance. While the process may seem straightforward, it requires care and precision to avoid damaging the delicate fiber optic cables. The following is a general guide to the installation process. It is always recommended to follow the specific instructions provided by the manufacturer and to have the installation performed by a qualified technician, especially for complex network setups. Safety should always be the top priority; tiny glass fragments from cleaved fibers can be hazardous if not handled correctly. For a detailed exploration of fiber installation safety and best practices, resources like the Fiber Optic Association (FOA) provide invaluable information.

- Prepare the Location: The first step is to choose the location for the faceplate. It should be easily accessible but also in a spot where the connecting cables will not be a tripping hazard. If installing in-wall, a low-voltage mounting bracket or junction box is typically installed first.

- Run the Cable: The main fiber optic cable is carefully routed from the distribution point to the faceplate location. It is crucial to avoid sharp bends, pulling with excessive force, or stapling the cable, as this can damage the fibers inside.

- Prepare the Fiber: At the faceplate, a sufficient length of cable is left for termination. The outer jacket is stripped back carefully to expose the buffered fibers inside. The fibers are then cleaned of any gel filling or protective coatings.

- Splice or Terminate: The fibers are then either fusion spliced to a pigtail or directly terminated with a field-installable connector. This is the most delicate step and requires specialized tools like a fiber cleaver and splicer for precision.

- Connect to the Faceplate: The terminated connector or pigtail is then plugged into the back of the adapter housed in the faceplate. Any excess fiber is carefully coiled and managed within the junction box or the faceplate’s management area.

- Mount and Test: The faceplate is then securely mounted to the wall. Once installed, the connection should be tested using an optical power meter or an Optical Time Domain Reflectometer (OTDR) to ensure that signal loss is within acceptable limits.

The Broader Ecosystem: Essential Fiber Optic Components

A Fiber Optic Faceplate is just one piece of a complex and interconnected ecosystem of components that work together to deliver high-speed data. To build a truly robust and efficient network, it is essential to use high-quality components throughout the entire channel, from the data center to the desktop. The performance of the network is only as strong as its weakest link. This is why at EPCOM, we offer a comprehensive range of fiber optic solutions designed to work seamlessly together. From high-density patch cords that form the backbone of data centers to the reliable adapters that ensure perfect alignment, every component plays a vital role. Understanding how these elements interact with the faceplate will give you a more holistic view of network design and help you build an infrastructure that is both powerful and resilient.

High-Density Connectivity with MPO/MTP Patch Cords

In environments that demand massive bandwidth and high-density connections, such as data centers and telecommunication hubs, standard connectors are often insufficient. This is where MPO/MTP (Multi-fiber Push-On/Multi-fiber Termination Push-on) technology becomes essential. An MPO/MTP Patch Cord bundles multiple fibers (typically 8, 12, or 24) into a single, compact connector. This allows for the rapid deployment of high-speed parallel optics links, such as 40G, 100G, and even 400G Ethernet. These patch cords connect high-density switches and servers, and their trunk cables are often broken out into individual connections at a patch panel, which then feeds into faceplates at the user end. The reliability of these backbone connections is critical, and using premium MPO/MTP cords ensures the entire network has the capacity to meet future demands.

The Importance of Reliable Connectors: The ST Fiber Optic Adaptor

The adapter is the heart of the faceplate, and its quality is non-negotiable. It performs the critical task of aligning two fiber connectors with sub-micron accuracy. The ST Fiber Optic Adaptor is a classic and highly reliable choice, known for its rugged, bayonet-style metal housing that provides a secure, spring-loaded connection. While newer, smaller connectors like the LC are more common in high-density applications, the ST connector remains a popular choice in industrial, military, and campus network environments due to its durability. A high-quality ST adaptor, featuring a precision ceramic alignment sleeve, ensures minimal insertion loss and consistent performance over many mating cycles. Whether it’s an ST, SC, or LC, choosing a well-made adaptor for your fiber optic faceplate is a key factor in network stability.

Safeguarding Connections with a Protection Box

In many FTTH deployments, the fiber optic cable enters the building from the outside, where it is exposed to the elements. Protecting the transition point from the outdoor-rated cable to the indoor cabling is essential. This is the role of a dedicated protection box. A device like EPCOM’s Protection Box with Adaptor is designed to be a durable, weatherproof enclosure made of robust ABS material. It typically houses the splice point where the external drop cable is joined to the indoor pigtail and provides a secure housing for an adapter. This box safeguards the delicate fiber connection from moisture, dust, and physical impact, ensuring the long-term reliability of the service drop. It is a critical first line of defense before the connection is routed indoors to the final fiber optic faceplate.

Common Applications of the Fiber Optic Faceplate

The versatility of the Fiber Optic Faceplate has led to its adoption across a vast range of industries and applications. Anywhere a high-speed, reliable, and secure data connection is required, you will likely find a fiber optic termination point. The fundamental benefits of fiber optic technology—immense bandwidth, immunity to electromagnetic interference, and enhanced security—make it the preferred choice for modern communication infrastructures. From connecting homes to the global internet to enabling the intricate operations of advanced medical equipment, the faceplate serves as the ubiquitous and essential final interface. Its role is set to expand even further as emerging technologies like the Internet of Things (IoT), 5G, and autonomous systems demand ever-faster and more reliable connectivity.

A Fiber Optic Faceplate in FTTH (Fiber to the Home)

Perhaps the most widespread application of the Fiber Optic Faceplate is in FTTH deployments. Internet service providers around the world are replacing aging copper networks with fiber to deliver gigabit-speed internet, high-definition television, and voice services to residential customers. In a typical FTTH setup, a drop cable is run from a nearby pole or underground conduit to the subscriber’s home. This cable is terminated at an external protection box, and then a smaller indoor cable is routed to a strategically placed fiber optic faceplate inside the house. The homeowner’s Optical Network Terminal (ONT), which functions as a modem, is then connected to the faceplate via a patch cord. This setup provides a dedicated, high-speed fiber link directly to the user, unlocking a world of digital possibilities.

Data Centers: The Nerve Center of the Digital World

Data centers are the backbone of the internet, and they rely heavily on fiber optics for their internal networking. The sheer volume of data being processed requires a network infrastructure that can handle massive throughput with ultra-low latency. While MPO/MTP connectors are used for high-density interconnects between racks of servers and switches, fiber optic faceplates are often used in administrative areas, network operation centers (NOCs), and at demarcation points connecting the data center to external carrier networks. The reliability and organization provided by these faceplates are crucial in such a mission-critical environment, where downtime can have significant financial and operational consequences. For more insights into how fiber optics are shaping modern data transmission, the Wikipedia page on Fiber-Optic Communication offers extensive background.

Corporate and Office Networks

In the corporate world, a reliable network is the lifeblood of productivity. Modern offices are increasingly adopting “fiber to the desktop” or “fiber to the zone” architectures to support bandwidth-intensive applications like video conferencing, cloud computing, and large data transfers. In this scenario, a Fiber Optic Faceplate is installed at each workstation or in a centralized location within a group of offices. This provides employees with a direct fiber connection, eliminating network bottlenecks and providing a level of security that copper-based LANs cannot match, as fiber optic signals are notoriously difficult to tap without being detected. This makes it an ideal solution for government, financial, and research institutions where data security is a top priority.

The Future of Connectivity and the Fiber Optic Faceplate

The future is undeniably connected, and fiber optics will be the foundational medium for this new era of communication. As technologies like 5G wireless, the Internet of Things (IoT), and artificial intelligence become more integrated into our daily lives, the demand for bandwidth will continue to grow exponentially. 5G towers require high-capacity fiber backhaul connections to deliver on their promise of high speed and low latency. Smart cities will deploy vast networks of sensors for traffic management, environmental monitoring, and public safety, all interconnected via fiber. The Fiber Optic Faceplate will continue to be the essential endpoint in this ever-expanding network, connecting smart homes, autonomous vehicles, and advanced medical devices to the global information superhighway. Its form may evolve to become smaller, smarter, and more integrated, but its fundamental role as the gateway to the network will remain.

Why Choose EPCOM for Your Fiber Optic Faceplate Needs?

When it comes to building a network that is reliable, scalable, and high-performing, the quality of your components matters. At EPCOM, we are dedicated to providing superior fiber optic solutions that meet the highest standards of quality and engineering. Our range of Fiber Optic Faceplate products is designed with both the installer and the end-user in mind. We use durable, high-grade materials to ensure longevity and robust performance. Our designs prioritize ease of installation and excellent cable management, saving you time and effort during deployment. By choosing EPCOM, you are not just buying a component; you are investing in a partnership with a company that is committed to your network’s success. We provide a comprehensive portfolio of products, from faceplates and adapters to patch cords and protection boxes, ensuring you can source a complete, high-quality solution from a single, trusted provider.

Conclusion: The Foundation of Future-Ready Networks

The Fiber Optic Faceplate, though small and often overlooked, is a powerhouse of connectivity. It is the critical juncture where the vast, high-speed world of the fiber optic network meets the end-user. Its role in protecting delicate connections, ensuring signal integrity, and providing organized access is indispensable for the performance and reliability of any modern network. From enabling seamless streaming in our homes to powering the data-intensive operations of global enterprises, the impact of this essential component is profound. As you plan your next network deployment or upgrade, remember that investing in a high-quality fiber optic faceplate from a reputable provider like EPCOM is a foundational step towards building an infrastructure that is not only powerful today but also ready for the challenges and opportunities of tomorrow. For a deeper dive into the expanding network applications driving this technology, industry resources like Fluke Networks’ blog provide excellent ongoing education.