The Ultimate Guide to MPO/MTP ODF for Data Centers

An MPO/MTP ODF (Optical Distribution Frame) is the cornerstone of modern, high-density network infrastructures, especially within data centers pushing the boundaries of speed and efficiency. As the demand for data escalates, driven by cloud computing, AI, and IoT, the need for a robust, scalable, and manageable cabling solution has never been more critical. This comprehensive guide will delve deep into the world of MPO/MTP ODFs, exploring their technology, benefits, applications, and the essential components that create a future-proof network. Furthermore, we will highlight how EPCOM’s cutting-edge solutions are empowering data centers to meet the challenges of today and the demands of tomorrow, including the transition to 400G and 800G speeds.

What Exactly Is an MPO/MTP ODF?

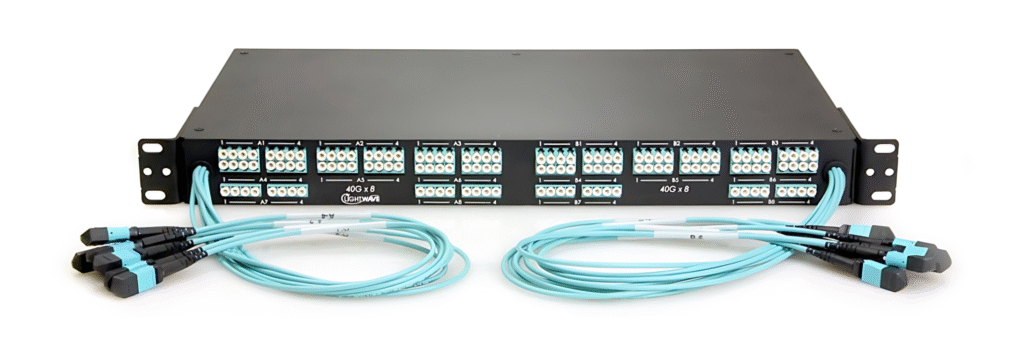

At its core, an MPO/MTP ODF is a passive network component that terminates and manages a large number of fiber optic connections in a compact space. Think of it as a central nervous system for your data center’s physical layer. The acronyms themselves stand for Multi-fiber Push-On (MPO) and Multi-fiber Termination Push-on (MTP), where MTP is a high-performance, enhanced version of the MPO connector. These connectors are the key innovation, allowing a single connector to house multiple fibers (typically 8, 12, 16, or 24). Consequently, an ODF equipped with these connectors can handle significantly more connections than traditional single-fiber (like LC or SC) ODFs, making it a high-density solution.

This density is not just about saving space; it’s about enabling a paradigm shift in network design. By consolidating connections, an MPO/MTP ODF simplifies cable management, reduces installation time, and provides a clear, scalable path for future upgrades. Instead of managing hundreds of individual patch cords, technicians can work with a smaller number of multi-fiber trunk cables, drastically reducing clutter and the potential for human error. This organized approach is fundamental for maintaining network uptime and performance in complex environments.

The Critical Need for a High-Density MPO/MTP ODF

In the digital age, data centers are the engines of the global economy. Their efficiency directly impacts business performance, research capabilities, and everyday connectivity. Traditional cabling methods, which involve single-fiber connectors, are no longer sustainable. They consume vast amounts of rack space, create a “spaghetti” of cables that obstructs airflow and complicates maintenance, and simply cannot scale to meet the bandwidth requirements of next-generation applications. This is where the benefits of a high-density MPO/MTP ODF become undeniable.

As detailed by industry leaders like FS.com, the advantages of high-density fiber solutions are multi-faceted. The first and most obvious benefit is space optimization. By housing more connections in a smaller footprint, data centers can maximize their expensive floor space. Secondly, this approach significantly enhances data throughput and bandwidth efficiency. An MPO/MTP ODF is essential for implementing parallel optics, the technology behind 40G, 100G, 400G, and even 800G Ethernet, where data is transmitted simultaneously over multiple fiber strands. Finally, the streamlined architecture of an MPO/MTP system enhances scalability, allowing networks to grow seamlessly without requiring a complete overhaul of the physical infrastructure.

EPCOM’s Advanced MPO/MTP ODF Solutions

EPCOM stands at the forefront of this technological evolution, offering a comprehensive suite of MPO/MTP ODF solutions designed for performance, reliability, and scalability. Our ODFs are engineered to provide a robust framework for managing high-density connections, facilitating everything from simple cross-connects to complex network architectures. By integrating our high-quality components, data centers can build an infrastructure that is not only powerful today but also ready for the advancements of the future.

Our product lineup, featured in our MPO/MTP ODF category, includes various configurations to meet diverse needs. From wall-mount units for smaller deployments to high-capacity rack-mount frames for large-scale data centers, EPCOM provides solutions that ensure easy access, superior cable management, and protection for critical fiber connections. These units are designed with modularity in mind, allowing for the easy addition of cassettes and adapter plates as your network expands.

The Building Blocks: Beyond the MPO/MTP ODF

An MPO/MTP ODF is the central hub, but its performance relies on a complete ecosystem of high-quality components working in harmony. Understanding these individual parts is crucial for designing and maintaining a high-performance network. These components ensure that the high-density connections established at the ODF are carried reliably throughout the data center, from server to switch.

1. The Lifeline: MPO/MTP Patch Cords

The primary carriers of data in this ecosystem are the MPO/MTP patch cords. These are not just simple cables; they are precision-engineered assemblies that bundle multiple fibers into a single, robust cable terminated with an MPO or MTP connector. An MPO/MTP Patch Cord from EPCOM is designed for superior performance, featuring low insertion loss and high return loss to ensure signal integrity. They are available in various fiber counts (8, 12, 16, 24), fiber types (singlemode, multimode OM3/OM4/OM5), and polarity configurations to support a wide range of applications, from backbone cabling to direct connections with active equipment. Using pre-terminated patch cords significantly accelerates deployment compared to field termination, a point strongly emphasized in comparisons of pre-terminated vs. field-terminated solutions.

2. The Connection Point: MPO/MTP Adaptors

Within the ODF, MPO/MTP adaptors play the critical role of aligning and connecting two MPO/MTP connectors. A precise and stable connection is vital to minimize signal loss at these junction points. The MPO/MTP Adaptor provided by EPCOM ensures a secure and perfectly aligned mating of connectors. These adaptors are designed with a specific keying orientation (key-up to key-down or key-up to key-up) to enforce correct polarity throughout the link, a critical aspect defined by the TIA-568 standard. This prevents connection mismatches that could otherwise bring down a critical network link.

3. The Guardian of Performance: MPO/MTP Cleaning Tools

A single speck of dust, invisible to the naked eye, can wreak havoc on a high-speed fiber optic connection. Contamination on a connector end-face can obstruct the light path, causing high insertion loss, bit errors, and even permanent damage to the connectors. In a multi-fiber MPO/MTP connector, the risk is amplified. This makes cleaning an indispensable part of any fiber optic maintenance routine. The MPO/MTP Cleaning Pen is an essential tool for every technician. It is specifically designed to clean the entire end-face of an MPO/MTP connector with a single, simple action, removing dust, oils, and other debris effectively. Regular use of this tool is the most cost-effective way to ensure network reliability and prevent costly downtime.

Technical Specifications and Types of MPO/MTP ODF

Not all MPO/MTP ODFs are created equal. They come in various shapes, sizes, and configurations to suit different environments and applications. Understanding these variations is key to selecting the right solution for your specific needs. The primary distinctions lie in their form factor, capacity, and the type of internal components they house.

Form Factors: Rack Mount vs. Wall Mount

The most common type of MPO/MTP ODF is the rack-mount version. These are designed to fit into standard 19-inch or 23-inch data center racks and are typically measured in rack units (U). A 1U ODF offers a compact solution, while 2U, 3U, or 4U models provide significantly higher capacity for large-scale deployments. Rack-mount ODFs often feature sliding trays or front/rear access panels to simplify the installation and maintenance of cables and cassettes.

Wall-mount MPO/MTP ODFs, on the other hand, are designed for environments where rack space is limited or unavailable, such as in telecommunications closets, industrial settings, or remote network nodes. They offer a secure and organized way to manage a smaller number of fiber connections while still providing the benefits of the MPO/MTP system.

Understanding MPO/MTP Connector Variations: 12, 16, and 24 Fibers

The MPO/MTP connector itself has evolved to support ever-increasing bandwidth needs. While the 12-fiber MPO connector has been a long-standing industry standard, newer variations are becoming prevalent:

- MPO-12: The workhorse of high-density cabling, often used for 40G (using 8 fibers) and 100G (using 8 or 10 fibers) applications. It provides a great balance of density and usability.

- MPO-16: This single-row 16-fiber connector is gaining traction for 400G applications. It aligns perfectly with the 8-lane (16-fiber) structure of many 400G transceivers (8 lanes for transmit, 8 for receive).

- MPO-24: This connector, with two rows of 12 fibers, offers the highest density. It is often used for high-density backbone (trunk) cabling, aggregating multiple 12-fiber links or providing a direct 100G connection using 20 fibers (10 transmit, 10 receive). You can learn more about these advanced connectors from resources like this article on MTP-16.

An MPO/MTP ODF from EPCOM can be configured with adapter plates that support any of these connector types, ensuring compatibility with your chosen network architecture and active equipment.

Installing and Maintaining Your MPO/MTP ODF System

Proper installation and diligent maintenance are crucial for realizing the full benefits of an MPO/MTP ODF system. While the plug-and-play nature of pre-terminated components simplifies deployment, a structured approach is still necessary to ensure long-term reliability and performance. Adhering to established data center cabling standards like TIA-942 is fundamental.

Installation Best Practices for Your MPO/MTP ODF

- Plan Your Layout: Before installing a single cable, map out your cabling pathways. A well-designed layout minimizes cable lengths, avoids potential sources of interference, and ensures that bend radius limits are respected.

- Inspect and Clean Before Connecting: This is the golden rule of fiber optics. Always inspect a connector with a fiber scope and clean it before mating it, even if it’s brand new and came with a protective cap.

- Ensure Correct Polarity: MPO/MTP systems use specific polarity methods (Method A, B, or C) to ensure that the transmitter at one end connects to the receiver at the other. Use the correct combination of trunk cables, cassettes, and patch cords to maintain the chosen polarity scheme throughout the link.

- Manage Cable Slack: Proper slack management is vital. Too much slack creates clutter and can lead to tangled, damaged cables. Too little slack puts stress on the connectors. Use horizontal and vertical cable managers within the rack to route and store slack neatly.

- Label Everything: A well-labeled infrastructure is a manageable one. Label every port on the ODF, every cable, and every cassette. This will save countless hours during troubleshooting, moves, adds, and changes (MACs).

Long-Term Maintenance

Maintenance for an MPO/MTP ODF system is primarily about cleanliness and organization. Regular visual inspections can help identify potential issues like damaged cables or improperly seated connectors. Periodically, it is wise to re-verify critical links with an Optical Loss Test Set (OLTS) or an Optical Time-Domain Reflectometer (OTDR) to ensure they are still performing within specification. And, of course, always keep a supply of cleaning tools, like the EPCOM MPO/MTP Cleaning Pen, readily available for technicians.

MPO/MTP ODF vs. Traditional ODF: A Comparison

To fully appreciate the impact of a modern MPO/MTP ODF, it’s helpful to compare it directly with a traditional ODF that uses single-fiber connectors like LC or SC. The differences in density, speed, and operational efficiency are stark.

| Feature | MPO/MTP ODF System | Traditional LC/SC ODF System |

|---|---|---|

| Connection Density | Extremely High. A 1U panel can support over 144 fibers, and some systems can go much higher. | Low to Medium. A 1U panel typically supports 48 to 96 fibers. |

| Rack Space Usage | Minimal. Maximizes connections per rack unit, saving valuable floor space. | Significant. Requires multiple rack units to achieve the same port count, increasing footprint. |

| Installation Speed | Very Fast. Pre-terminated trunk cables allow for rapid, plug-and-play deployment. | Slow. Often requires time-consuming field termination of individual connectors or splicing of pigtails. |

| Cable Management | Simplified. A single trunk cable replaces 8, 12, or 24 individual patch cords, reducing clutter. | Complex and Prone to Clutter. Managing hundreds of individual jumpers is challenging and obstructs airflow. |

| Scalability for Future Speeds | Excellent. Natively supports parallel optics required for 40G, 100G, 400G, and beyond. | Limited. Scaling to higher speeds often requires a complete and costly re-cabling of the infrastructure. |

| Human Error Risk | Lower. Factory-tested, pre-terminated components ensure consistent performance and reduce on-site errors. | Higher. Field terminations are dependent on technician skill, and managing many individual connections increases the chance of mispatching. |

Future-Proofing Your Network with an MPO/MTP ODF

Choosing an infrastructure solution is a long-term investment. The decisions made today will determine a network’s ability to adapt to the technological landscape of the next five to ten years. Adopting an MPO/MTP ODF strategy is fundamentally about future-proofing. The rate of data growth is not slowing down, and the transition from 100G to 400G is already well underway in hyperscale and cloud data centers, with 800G and 1.6T on the horizon.

These next-generation speeds rely almost exclusively on parallel optics over multi-fiber infrastructure. An MPO/MTP cabling plant, managed by a high-density ODF, is the only practical way to support this evolution. It provides a clear migration path. For instance, a 24-fiber MPO trunk cable can be used today to support twelve 10G duplex channels. Tomorrow, the same trunk cable can be repurposed to support a 100G link. In the future, it could support three 400G links using MPO-8 connectors via a breakout module. This flexibility, enabled by the modularity of the MPO/MTP ODF system, ensures that your initial investment continues to deliver value for years to come, protecting your TCO (Total Cost of Ownership).

Conclusion: The Smart Choice for Modern Data Centers

The MPO/MTP ODF is no longer a niche solution for hyperscalers; it is the definitive standard for any data center that values efficiency, scalability, and reliability. The immense benefits—from superior space optimization and simplified cable management to rapid deployment and a clear path to future network speeds—make it an indispensable component of modern network design. By consolidating connectivity into a high-density, manageable platform, the MPO/MTP ODF solves the physical layer challenges posed by the exponential growth in data traffic.

EPCOM is committed to providing the highest quality MPO/MTP ODF systems and supporting components to help you build a robust and future-proof network. From our versatile ODF frames to our precision-engineered patch cords, adaptors, and essential cleaning tools, we offer a complete ecosystem designed for performance. By choosing EPCOM, you are not just buying components; you are investing in a partnership with a leader in fiber optic technology, dedicated to helping you navigate the complexities of data center connectivity and achieve your operational goals.