The Ultimate Overview of Fiber Optic Fast Connector

A Fiber Optic Fast Connector is a revolutionary component in the telecommunications industry, designed to simplify the process of terminating fiber optic cables in the field. As the world’s demand for faster, more reliable data transmission skyrockets, the need for efficient network installation and maintenance has become paramount. Gone are the days when terminating fiber required complex, time-consuming procedures and expensive equipment. The advent of the fast connector, also known as a quick connector or field-installable connector, has empowered technicians to establish high-quality connections in minutes, not hours. This technology is a cornerstone of modern network deployment, especially in applications like Fiber to the Home (FTTH), data center management, and emergency network restoration. This comprehensive article delves deep into the world of the fiber optic fast connector, exploring its mechanics, advantages, types, installation processes, and critical role in shaping the future of digital connectivity. We will also highlight how EPCOM’s superior range of connectivity solutions can elevate your network infrastructure.

The Journey from Traditional Splicing to Fast Connectors

To fully appreciate the innovation of the fiber optic fast connector, it’s essential to understand the methods it was designed to improve upon. Historically, creating a permanent connection between two fiber optic cables was primarily achieved through fusion splicing. This method involves using a specialized machine, a fusion splicer, to precisely align the two fiber ends and then apply an electric arc to melt or “fuse” them together, creating a nearly seamless, permanent joint. While fusion splicing offers excellent performance with very low signal loss, it has significant drawbacks. The equipment is costly, bulky, and requires a stable, clean environment and a highly skilled operator. This makes it less than ideal for rapid field deployments, cramped spaces, or situations where only a few terminations are needed.

The alternative was traditional connectorization, which involved a multi-step process of gluing the fiber into a connector ferrule, followed by meticulous hand-polishing. This method, while not requiring a splicer, was labor-intensive, messy, and highly dependent on technician skill for a successful outcome. The inconsistency and time involved were major bottlenecks in network expansion. Recognizing these challenges, manufacturers engineered a solution that combined the ease of a mechanical connection with the performance of a factory-polished one. This innovation was the fiber optic fast connector, a pre-polished, pre-assembled connector that uses an internal mechanical splice to securely grip the field fiber, eliminating the need for epoxy, polishing, or expensive machinery.

Deconstructing the Fiber Optic Fast Connector

At its core, a fiber optic fast connector is a clever piece of engineering that houses a factory-polished fiber stub within its ceramic ferrule. This stub is precisely cleaved and polished in a controlled factory environment to ensure optimal performance. Inside the connector body, a mechanical splice mechanism and a special index-matching gel are waiting. When a technician inserts a properly prepared field fiber, the mechanical splice aligns it with the internal fiber stub. The index-matching gel fills the microscopic air gap between the two fiber ends, minimizing signal reflection (return loss) and signal attenuation (insertion loss). A simple clamping or wedging mechanism is then activated, securely locking the field fiber in place. This entire process is completed in under two minutes, providing a reliable, high-performance connection that rivals traditional methods but with a fraction of the time, cost, and complexity. This makes the technology indispensable for modern, large-scale network rollouts.

Why Technicians Prefer the Fiber Optic Fast Connector

The widespread adoption of the fiber optic fast connector is due to a compelling set of advantages that directly address the pain points of older termination methods. These benefits streamline workflow, reduce operational costs, and enhance network reliability.

- Unmatched Installation Speed: The most significant advantage is speed. A technician can complete a termination in as little as one to two minutes, drastically reducing installation time per connection point. For large projects like FTTH rollouts, this time saving translates into substantial labor cost reductions and faster project completion.

- Minimal Tooling and Investment: Unlike fusion splicing, fast connectors do not require a costly fusion splicer or an electrical power source. The essential tools are basic fiber preparation tools, such as a stripper and a high-precision cleaver. This lowers the barrier to entry for technicians and contractors.

- Simplicity and Ease of Use: The installation process is straightforward and requires minimal training. This reduces the risk of human error and ensures a high success rate, even for technicians who are new to fiber optics. The result is consistent and reliable performance across the network.

- Portability and Field Readiness: Fast connectors and their associated tools are compact and lightweight, making them perfect for fieldwork. Technicians can easily carry everything they need to perform terminations in various environments, from data center cabinets to aerial closures and customer premises.

- High Success Rate and Reusability: Most modern fiber optic fast connector designs allow for re-termination. If the initial termination does not meet performance standards (e.g., due to a poor cleave), the technician can often open the connector, remove the fiber, re-cleave it, and try again. This minimizes waste and material costs.

- Cost-Effectiveness: While the per-unit cost of a fast connector might be higher than a traditional splice-on connector, the total cost of ownership is significantly lower when factoring in the savings on labor, training, and expensive equipment.

Exploring the Types of Fiber Optic Fast Connectors

The term “fiber optic fast connector” encompasses a wide range of products designed for different applications, cable types, and performance requirements. Understanding these variations is key to selecting the right component for your network. EPCOM offers a comprehensive selection to meet diverse project needs.

Classification by Connector Interface: The Common Fiber Optic Fast Connector Formats

Fast connectors are available in all standard industry interfaces to ensure compatibility with existing hardware and network designs.

- SC (Subscriber Connector): This is one of the most popular types, especially in FTTH and CATV applications. The SC fast connector features a simple push-pull mating mechanism, making it easy to use in dense patch panels. Its square shape provides stability.

- LC (Lucent Connector): With a ferrule half the size of an SC connector, the LC fast connector allows for much higher port density. It is the dominant choice for high-bandwidth applications like data centers, central offices, and LANs.

- ST (Straight Tip): While less common in new installations, the ST fast connector is still prevalent in older enterprise networks and military applications. It uses a robust bayonet-style locking mechanism that ensures a secure connection.

- FC (Ferrule Connector): Known for its threaded, screw-on coupling, the FC fast connector provides excellent stability and vibration resistance. It’s often used in testing equipment, industrial settings, and single-mode applications where precision is critical.

Classification by Polish Type: The UPC vs. APC Fiber Optic Fast Connector

The polish of the connector’s end-face is crucial for performance, particularly for return loss, which is the amount of light reflected back toward the source.

- UPC (Ultra Physical Contact): A UPC connector has a slightly domed end-face, which ensures that the fiber cores make direct contact. This results in good performance with low insertion loss and a return loss of around -50dB. UPC connectors are typically blue and are suitable for most digital data applications.

- APC (Angled Physical Contact): An APC connector features an end-face that is polished at an 8-degree angle. This angle causes reflected light to bounce into the fiber cladding instead of back to the source. This results in outstanding return loss performance (better than -60dB). APC connectors are typically green and are the standard for RF video signal transmission (like in CATV) and passive optical networks (PON).

Crucial Note: UPC and APC connectors are not interchangeable and should never be mated together, as this can cause high loss and permanent damage to both connectors.

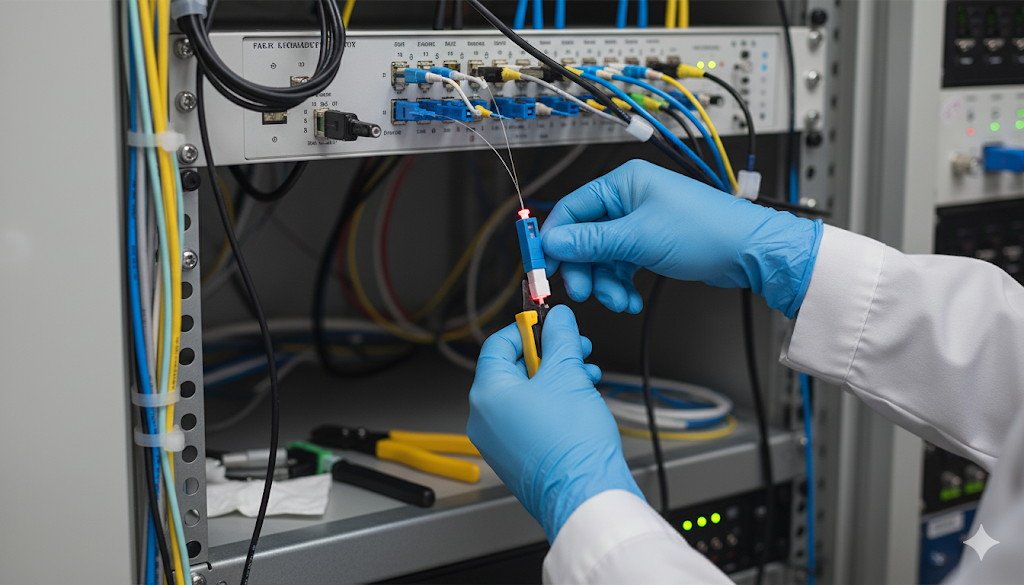

Installation of a Fiber Optic Fast Connector: A Step-by-Step Walkthrough

The simplicity of installing a fiber optic fast connector is its greatest strength. While specific steps may vary slightly between manufacturers, the fundamental process remains consistent. Here is a general guide to a successful field termination.

- Gather Your Tools and Materials: Before starting, ensure you have all the necessary items: the fiber optic fast connector, the fiber cable, a visual fault locator (VFL), lint-free wipes, isopropyl alcohol, a fiber stripper, and a high-precision fiber cleaver. The quality of your tools is paramount for a good connection.

- Prepare the Cable: Slide the connector’s screw-on boot over the cable. Then, using a reliable stripper like the 4-5-29mm Round Cable Stripper, carefully remove the outer jacket of the cable to the length specified in the connector’s instructions (usually around 45-50mm). This tool is designed to precisely cut the jacket without damaging the delicate fibers inside.

- Strip the Fiber Coating: Next, use a fiber optic stripper to remove the 250μm buffer coating and expose the 125μm cladding. Be sure to strip to the exact length indicated by the template provided with the connector. This step must be done in a single, smooth motion to avoid damaging the fiber.

- Clean the Bare Fiber: This is a critical step. Moisten a lint-free wipe with 99% isopropyl alcohol and gently wipe the bare fiber to remove any debris or coating residue. A clean fiber is essential for a low-loss connection.

- Cleave the Fiber: Place the cleaned fiber into a high-precision cleaver. The cleaver will score and break the glass fiber to create a perfectly flat end-face that is perpendicular to the fiber axis. The quality of the cleave is the single most important factor in achieving good performance. An ideal cleave angle should be less than 0.5 degrees.

- Insert the Fiber into the Connector: Carefully insert the cleaved fiber into the back of the fiber optic fast connector. You will feel it make contact with the internal fiber stub. Gently push the fiber to create a slight bow; this ensures a secure physical contact between the two fiber ends.

- Activate the Locking Mechanism: While maintaining the slight fiber bow, activate the connector’s wedge or cam-locking mechanism. This will clamp the fiber securely in place. You will feel and see the bow straighten as the mechanism engages.

- Final Assembly and Testing: Screw the connector boot onto the body. Finally, plug a visual fault locator (VFL) into the connector. If the installation is successful, you will see very little or no red light leaking from the connector body. A bright red glow indicates a poor cleave or another issue, and the fiber should be re-terminated.

Essential Tools and Complementary Network Hardware

While the fiber optic fast connector is the star of the show, a successful network installation relies on a system of high-quality tools and components working in harmony. A technician’s toolkit must be equipped for precision and efficiency, and the passive network hardware must maintain the integrity of the connections created.

The Technician’s Essential Toolkit

Beyond the basic hand tools, a few key pieces of equipment are non-negotiable for professional fiber optic work. A high-precision cleaver is arguably the most important tool, as it directly impacts the performance of every termination. A visual fault locator (VFL) is an invaluable diagnostic tool for quickly identifying breaks, macrobends, or faulty connections. Of course, keeping a plentiful supply of fiber-specific cleaning materials is fundamental to good practice. For ensuring the cable is perfectly prepped, a professional-grade stripper is essential. The 4-5-29mm Round Cable Stripper from EPCOM is an excellent example of a tool built for this purpose, providing consistent results without risking fiber damage.

Completing the Connection: From Wall to Equipment

The work doesn’t end once the connector is on the cable. This terminated fiber needs a secure and organized point to interface with the rest of the network. This is where components like wall sockets and adaptors come into play.

At the customer’s premises, a Fiber Optic Wall Socket with 2 Ports provides a clean, professional, and protective housing for the termination points. This unit neatly manages the incoming cable and provides one or more standard ports where patch cords can be connected, linking the network to the end-user’s equipment (like an Optical Network Terminal, or ONT). It protects the delicate fiber connections from dust, damage, and accidental disconnects.

In patch panels, distribution frames, or when connecting two cables, a fiber optic adaptor (also called a coupler or mating sleeve) is required. An adaptor like the ST Fiber Optic Adaptor ensures precise alignment between the ferrules of the two connectors being mated. Its high-precision alignment sleeve (typically made of ceramic for single-mode) minimizes insertion loss and maintains the integrity of the signal path. EPCOM provides a wide array of adaptors for all standard connector types, ensuring seamless integration within your network infrastructure.

Where is the Fiber Optic Fast Connector Used Most?

The versatility and efficiency of the fiber optic fast connector have made it a go-to solution in a wide array of networking scenarios. Its ability to provide rapid, reliable terminations in any environment is invaluable.

- Fiber to the Home (FTTH): This is arguably the largest application area. Fast connectors are used to terminate the final drop cable at the subscriber’s home, connecting it to the wall socket. Their speed is essential for technicians who may need to complete dozens of home installations in a single day.

- Data Center Operations: In data centers, where thousands of connections are managed, fast connectors are used for making custom-length patch cords, performing rapid repairs, or connecting new equipment without disrupting services. The ability to create a high-performance link quickly is a major asset.

- Campus and Enterprise LANs: For corporate and university campuses, fast connectors are used to build out the local area network (LAN), connect buildings, and set up fiber-to-the-desk applications.

- Emergency Network Restoration: When a fiber cable is accidentally cut, restoring service quickly is the top priority. A fiber optic fast connector allows a technician to quickly terminate the broken ends and join them with an adaptor, creating a temporary or even permanent repair in a fraction of the time it would take to set up a fusion splicer. For more detailed information on fiber optic best practices, industry standards are often defined by organizations like The Fiber Optic Association (FOA).

- Testing and Measurement: Technicians often use fast connectors to create temporary launch cables or test leads in the field for use with an Optical Time-Domain Reflectometer (OTDR) or other testing equipment.

Evaluating a High-Quality Fiber Optic Fast Connector

Not all fast connectors are created equal. When selecting a fiber optic fast connector for your project, it’s crucial to evaluate its performance specifications. These metrics, typically provided by the manufacturer, determine the quality and reliability of the connection you can expect to achieve. EPCOM prides itself on providing components that meet or exceed industry standards.

- Insertion Loss (IL): This is the most critical metric. It measures the amount of optical power lost as the signal passes through the connector. A lower IL value is better. High-quality fast connectors typically have an average IL of less than 0.3dB.

- Return Loss (RL): This measures the amount of light that is reflected back toward the source. A higher RL value is better, as it indicates less reflection. For UPC connectors, an RL of >50dB is expected. For APC connectors, it should be >60dB. High reflections can destabilize laser light sources and corrupt data signals.

- Durability: This refers to the number of times a connector can be mated and unmated (mating cycles) before its performance degrades. A typical specification is around 500 cycles.

- Tensile Strength: This measures the connector’s ability to withstand pulling force on the cable without the fiber pulling out or the performance degrading. A strong mechanical grip is essential for long-term reliability.

- Operating Temperature: This specifies the range of temperatures within which the connector will perform to its specifications. This is particularly important for outdoor or industrial installations where the connector may be exposed to extreme conditions.

Fiber Optic Fast Connector vs. Fusion Splicing: A Comparison

| Feature | Fiber Optic Fast Connector | Fusion Splicing (Splice-On Connector) |

|---|---|---|

| Initial Cost | Low (requires basic tools) | Very High (requires expensive fusion splicer) |

| Performance (Insertion Loss) | Good (typically < 0.3dB) | Excellent (typically < 0.1dB) |

| Installation Time | Very Fast (1-2 minutes) | Slower (5-10 minutes, including setup) |

| Required Skill Level | Low to Moderate | High (requires extensive training) |

| Field Reliability | High (dependent on a good cleave) | Very High (creates a near-permanent bond) |

| Power Requirement | None | Yes (battery or mains power for splicer) |

The Future Role of the Fiber Optic Fast Connector

The digital landscape is in a state of constant evolution. The rollout of 5G networks, the proliferation of the Internet of Things (IoT), the growth of cloud computing, and the demand for ultra-high-definition streaming all place unprecedented strain on our global data infrastructure. This insatiable demand for bandwidth means that fiber optic networks must be built out faster and more efficiently than ever before. The fiber optic fast connector is not just a component of this expansion; it is a critical enabler.

The ability to rapidly deploy high-performance fiber links is the backbone of this growth. Fast connectors will continue to be essential for scaling FTTH networks to connect more homes, for building the dense fiber backbones required by 5G small cells, and for enabling the agile, on-demand connectivity required in modern data centers. As technology advances, we can expect to see further innovations in fiber optic fast connector design, such as even lower loss rates, smaller form factors, and enhanced durability to withstand harsher environments. For more insights into emerging trends, industry publications like Lightwave offer expert analysis on the future of optical networking.

Termination Method Time Comparison

Troubleshooting a Faulty Fiber Optic Fast Connector Installation

Even with a simplified process, issues can occasionally arise during the installation of a fiber optic fast connector. Fortunately, most problems are easy to diagnose and fix. The key is to be methodical and understand the common points of failure.

- Problem: High Insertion Loss. The most common issue. This is almost always caused by a poor cleave. If the fiber end-face is not perfectly flat and angled, the light will not couple efficiently with the internal fiber stub.

Solution: Re-terminate. Open the connector’s locking mechanism, carefully remove the fiber, clean it, and perform a new cleave. Ensure your cleaver blade is sharp and clean. - Problem: High Return Loss / VFL Light Bleeding. This indicates a significant air gap or contamination between the fiber end-faces. It can be caused by a bad cleave, a dirty fiber, or failing to create the slight fiber “bow” before locking the mechanism.

Solution: First, ensure the fiber was properly cleaned. If it was, the issue is likely the physical contact. Re-terminate, making sure to push the fiber in until it bows slightly before engaging the lock. This bow provides the necessary compression for good physical contact. - Problem: Fiber Breaks During Insertion. This happens when the fiber snags on something inside the connector or if too much force is applied.

Solution: Check the connector’s internal channel for any debris or obstruction. When inserting the fiber, use a firm but gentle, steady pressure. Do not force it. Ensure the fiber is perfectly straight as it enters the connector body. - Problem: The Connector Fails to Lock. The internal mechanism might be jammed or the fiber may not be inserted far enough to allow the cam to engage.

Solution: Remove the fiber and inspect the locking mechanism. Try actuating it without a fiber inside to ensure it moves freely. When re-inserting the fiber, make sure it goes all the way to the end of its path.

Why Trust EPCOM for Your Fiber Optic Fast Connector Needs?

In the world of network infrastructure, quality and reliability are not optional. Every connection point is a potential point of failure, and using substandard components can lead to costly downtime and performance issues. This is why choosing a trusted partner for your connectivity needs is essential. EPCOM has built its reputation on providing high-performance, professional-grade telecommunications solutions.

Our range of fiber optic fast connectors is manufactured to the highest quality standards, ensuring you achieve low insertion loss and excellent return loss for every termination. We understand that a successful installation depends on more than just the connector, which is why we also offer a complete ecosystem of tools and passive components, from precision strippers and cleavers to durable wall sockets and adaptors. By choosing EPCOM, you are not just buying a product; you are investing in a reliable network foundation backed by expertise and a commitment to customer success.

The fiber optic fast connector has fundamentally changed how we build and maintain communication networks, making them more accessible, scalable, and resilient. It is a small component that plays a massive role in our connected world. To build a network that is ready for the demands of tomorrow, start with the right components today. Explore EPCOM’s extensive catalog of fiber optic solutions and empower your technicians to build better networks, faster.