Fiber Optic Adaptors: The Ultimate Guide for 2025

Fiber Optic Adaptors are fundamental components in the architecture of modern digital infrastructure, yet their critical role is often overlooked. These small but mighty devices serve as the essential bridge, enabling the seamless connection of two fiber optic cables. Consequently, they ensure that the precious data, transmitted as pulses of light, continues its journey with minimal loss and maximum integrity. In any high-performance fiber network, from sprawling data centers to robust telecommunication systems, the quality of these adaptors can make the difference between flawless operation and frustrating downtime. As a leading provider of state-of-the-art connectivity solutions, EPCOM understands that precision is paramount. Therefore, this guide will delve deep into the world of fiber optic adaptors, exploring their types, applications, and the critical specifications that define their performance.

The primary function of a fiber optic adaptor, sometimes called a coupler or a mating sleeve, is to align the cores of two fiber optic connectors with microscopic precision. This alignment is crucial because any deviation can lead to significant signal degradation, known as insertion loss. Furthermore, these adaptors provide a stable and secure housing for the connectors, protecting the delicate fiber ends from physical damage, dust, and other contaminants that could impede performance. Whether you are expanding an existing network or building a new one from the ground up, selecting the right fiber optic adaptors is a foundational step toward achieving reliability and speed. This guide aims to be your definitive resource, empowering you with the knowledge to make informed decisions for your connectivity needs.

Why are Fiber Optic Adaptors a Non-Negotiable Necessity?

In the intricate web of fiber optics, every component plays a role. However, fiber optic adaptors are particularly indispensable. They are not merely connectors but precision instruments of alignment. Without them, linking fiber segments would be an unreliable, lossy, and impractical task. They provide the mechanical and optical interface necessary for a robust and repeatable connection, forming the backbone of a scalable network.

The Principle of Precision Alignment

At the heart of every fiber optic adaptor is the alignment sleeve. This tiny cylinder is engineered with extreme precision to hold the ferrules of two connectors in perfect alignment. The ferrule is the rigid, polished tip of the fiber optic connector that houses the glass fiber core. When two ferrules are inserted into the adaptor’s alignment sleeve, they are brought into direct, physical contact. The goal is to make the two separate fiber cores behave as if they were one continuous strand, allowing light to pass through the junction with the least possible disruption. This precision is measured in microns, and even the slightest misalignment can scatter the light signal, weakening its strength.

Maintaining Signal Integrity with Quality Fiber Optic Adaptors

Signal integrity is the measure of the quality of the transmitted signal. Two key metrics dictate this in a fiber connection: insertion loss and return loss. A high-quality fiber optic adaptor directly contributes to optimizing both.

Insertion Loss: This is the reduction in signal power resulting from the insertion of a device in a transmission line. A superior adaptor minimizes this loss by ensuring the tightest possible alignment.

Return Loss: This refers to the light that is reflected back toward the source from a connection point. High return loss (meaning less light is reflected back) is desirable. Reflections can destabilize laser light sources and corrupt the transmitted data. A well-designed adaptor ensures that the connector ferrules make optimal physical contact, minimizing air gaps that cause reflections.

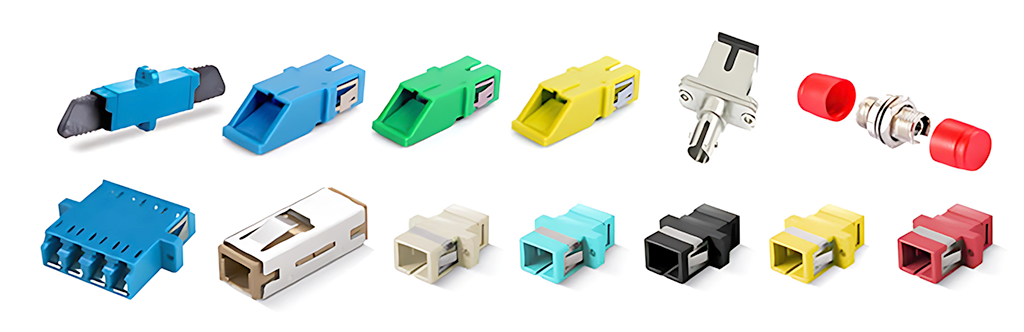

A Deep Dive into the Common Types of Fiber Optic Adaptors

The world of fiber optics is diverse, with various connector types developed for specific applications. Consequently, a wide range of fiber optic adaptors exists to accommodate them. Understanding the differences between these types is essential for ensuring compatibility and performance within your network infrastructure. EPCOM offers a comprehensive selection to meet these varied demands. Below, we explore the most prevalent types in the industry.

LC (Lucent Connector) Fiber Optic Adaptors

LC fiber optic adaptors are a modern standard, prized for their small form factor and high-performance capabilities. Developed by Lucent Technologies, the LC connector features a 1.25mm ferrule, half the size of the older SC connector. This compact design allows for extremely high-density installations, making them the go-to choice for data centers, server farms, and other environments where space is at a premium. The connector uses a reliable retaining tab mechanism, similar to an RJ45 Ethernet connector, which provides a secure, audible click upon connection. LC adaptors are available in simplex (for one fiber) and duplex (for two fibers) configurations and are widely used for both single-mode and multimode applications.

SC (Subscriber Connector) Fiber Optic Adaptors

The SC fiber optic adaptor is another ubiquitous component in the telecommunications industry. Featuring a 2.5mm ferrule, it utilizes a simple and effective push-pull mating mechanism. This design provides a quick, easy, and stable connection, and its square shape allows for dense mounting on panels. While its larger size means it’s less space-efficient than the LC, its ruggedness and excellent performance have made it a long-standing favorite for data and telecom applications, including point-to-point and passive optical networking (PON). SC adaptors are known for their low insertion loss, low back reflection, and high reliability over many mating cycles.

ST (Straight Tip) Fiber Optic Adaptors

ST fiber optic adaptors are one of the pioneering designs in the industry. They are easily recognizable by their bayonet-style mount, which requires a push and a twist to secure the connection. This locking mechanism provides a very secure and vibration-resistant link, which made it extremely popular in early LAN environments, as well as in industrial and military applications where physical stability is critical. Like the SC, it uses a 2.5mm ferrule. While ST connectors are being phased out in many data center and telecom environments in favor of smaller, more convenient options like the LC, they remain prevalent in legacy systems and specific industrial fields.

FC (Ferrule Connector) Fiber Optic Adaptors

FC fiber optic adaptors are known for their precision and durability. They utilize a threaded screw-on mating mechanism, which provides a very tight and secure connection that is highly resistant to vibration and shock. This makes FC adaptors ideal for high-vibration environments and for laboratory settings where precise instrumentation and measurement are required. They also use a 2.5mm ferrule and were one of the first connector types to use a ceramic ferrule, setting a standard for low-loss single-mode connections. Although largely superseded by SC and LC connectors in general applications, FC connectors are still the preferred choice for specific high-precision equipment like OTDRs (Optical Time-Domain Reflectometers).

MPO/MTP (Multi-fiber Push-On) Fiber Optic Adaptors

MPO/MTP fiber optic adaptors represent the cutting edge of high-density connectivity. Unlike the other adaptors that connect a single fiber (or two in a duplex setup), a single MPO/MTP adaptor can connect a ribbon cable containing 12, 24, or even more fibers. This incredible density is essential for enabling the high-speed data links (40G, 100G, and beyond) required by modern hyperscale data centers and telecommunications backbones. The MTP connector is a high-performance version of the MPO with improved mechanical and optical characteristics. These adaptors are key to deploying parallel optics and simplifying complex cable management.

Hybrid and Shuttered Fiber Optic Adaptors

Beyond standard adaptors that connect two connectors of the same type, there are also specialized versions. Hybrid fiber optic adaptors are designed to connect two different types of fiber optic connectors, such as an LC connector to an SC connector. These are invaluable for integrating new equipment with legacy systems without having to re-terminate cables. Shuttered adaptors feature an internal or external spring-loaded shutter that automatically covers the adaptor opening when a connector is not inserted. This provides excellent protection against dust contamination and also enhances eye safety by blocking any stray laser light.

Decoding the Specifications: What to Look for in Fiber Optic Adaptors

Choosing the right fiber optic adaptor goes beyond just matching the connector type. Several key specifications determine the adaptor’s performance, durability, and suitability for a particular environment. Understanding these parameters, which are central to the quality commitment of EPCOM, ensures you select a product that will uphold the integrity of your network.

Single-mode vs. Multimode Fiber Optic Adaptors

This is one of the most fundamental distinctions. The choice depends entirely on the type of fiber cable being used.

Single-mode (SM) adaptors are designed for single-mode fiber (typically with a 9/125µm core). They require extremely precise alignment to handle long-distance, high-bandwidth signals with minimal loss. They are often color-coded blue (for UPC) or green (for APC).

Multimode (MM) adaptors are used with multimode fiber (e.g., 50/125µm or 62.5/125µm). The larger core of multimode fiber is more forgiving of slight misalignments. These adaptors are typically color-coded beige or aqua (for OM3/OM4). While it’s physically possible to mate connectors in the wrong type of adaptor, it will result in significant performance issues.

Alignment Sleeve Material: The Heart of the Adaptor

The material of the internal alignment sleeve is arguably the most critical factor in an adaptor’s performance and longevity. The two primary materials used are phosphor bronze and zirconia ceramic.

Phosphor Bronze: This is a metal alloy sleeve primarily used for multimode applications. It provides good, reliable performance at a lower cost. However, it is softer than ceramic and can wear down or deform over repeated mating cycles, which can degrade alignment precision over time.

Zirconia Ceramic: This is the superior material, and it is the standard for all single-mode and high-performance multimode applications. Ceramic is extremely hard and durable, allowing it to maintain its precise shape and tight tolerances over thousands of mating cycles. Its smooth surface also reduces friction and debris generation. While more expensive, the reliability and long-term stability of zirconia ceramic sleeves make them the preferred choice for any critical network link. EPCOM prioritizes zirconia sleeves for its premium adaptors to guarantee the best possible performance.

To clarify the differences, here is a comparison table:

| Feature | Zirconia Ceramic Sleeve | Phosphor Bronze Sleeve |

|---|---|---|

| Primary Application | Single-mode (required) & High-Performance Multimode | Multimode (standard) |

| Durability (Mating Cycles) | Very High (typically >1000 cycles) | Good (typically ~500 cycles) |

| Alignment Precision | Extremely High, stable over time | Good, can degrade slightly with wear |

| Insertion Loss | Very Low (typically < 0.2dB) | Low (typically < 0.3dB) |

| Cost | Higher | Lower |

Simplex vs. Duplex Fiber Optic Adaptors

This specification relates to the number of fibers being connected.

Simplex means the adaptor is designed to connect a single fiber optic connector. This is used for applications that require one-way data transmission.

Duplex adaptors are designed to connect two fibers simultaneously. They are essentially two simplex adaptors housed together in a single unit. This is standard for most communication devices (like media converters or switches) that require simultaneous, two-way (bi-directional) data transmission.

Key Applications: Where Fiber Optic Adaptors Power Our World

Fiber optic adaptors are not confined to a single industry; they are the unsung heroes in a vast array of fields. Their ability to provide reliable, high-speed connections makes them indispensable wherever data needs to move quickly and securely. From the global internet backbone to specialized medical devices, these components are everywhere.

Telecommunications and Hyperscale Data Centers

This is the largest and most demanding sector for fiber optic components. In massive data centers and central telecom offices, thousands upon thousands of connections must be made in densely packed racks. High-density adaptors, especially LC and MPO types, are critical. They enable the deployment of countless servers, switches, and storage units that power cloud computing, streaming services, and global communications. Reliability is non-negotiable, as a single failed connection can affect thousands of users. This is why adherence to standards from organizations like the Telecommunications Industry Association (TIA) is so crucial.

Enterprise and Local Area Networks (LAN)

In corporate offices, university campuses, and hospitals, fiber optics form the high-speed backbone of the Local Area Network. Fiber is used to connect buildings and to link distribution closets to the main server room. In these environments, SC and LC adaptors are commonly found in wall outlets and patch panels, providing a convenient and reliable point of connection for network hardware. They provide the bandwidth needed to support thousands of users and data-intensive applications.

Military, Aerospace, and Industrial Applications

In these harsh environments, components must be able to withstand extreme temperatures, shock, and vibration. FC and ST adaptors, with their secure threaded and bayonet locking mechanisms, are often favored. Fiber optics are used in avionics for their light weight and immunity to electromagnetic interference (EMI). In industrial settings, they are used for process control and sensing in environments where electrical noise from heavy machinery would disrupt traditional copper wiring. The durability of the fiber optic adaptors in these scenarios is of paramount importance.

The EPCOM Ecosystem: More Than Just Adaptors

A truly robust fiber optic network is a system where every component works in harmony. While high-quality fiber optic adaptors are a cornerstone, they are part of a larger ecosystem of products designed to ensure peak performance, testability, and longevity. At EPCOM, we provide a holistic solution, understanding that connectivity is a chain only as strong as its weakest link.

Ensuring Link Integrity with Test and Measurement Tools

How do you verify that a newly installed link is performing to specification? How do you troubleshoot a connection that has gone down? This requires specialized testing tools. One of the most fundamental tests involves reflecting a signal back to the testing device (like a power meter or OTDR) to measure loss. For this purpose, a loopback is an essential piece of equipment for any fiber technician. The LC Optical Loopback from EPCOM is a compact and effective tool designed precisely for this. It provides a simple and reliable way to test the transmission capability and receiver sensitivity of network equipment, making it indispensable for network diagnostics and device burn-in testing.

Completing the Connection with High-Quality Cables

Your premium fiber optic adaptors need to be paired with equally high-quality cables. The adaptors create the bridge, but the patch cords carry the signal between devices and the patch panel. Using substandard cables with premium adaptors is a recipe for poor performance. EPCOM offers a comprehensive range of fiber patch cords, available in various lengths, connector types (LC, SC, etc.), and fiber modes (single-mode, multimode). Each cable is manufactured to exacting standards to ensure low loss and excellent performance, guaranteeing a perfect connection when used with our adaptors.

The Critical Importance of Cleanliness and Maintenance

The single greatest cause of fiber optic network failure is contaminated connector end-faces. A microscopic speck of dust, invisible to the naked eye, can obstruct the fiber core, causing high insertion loss and back reflection. Every time a connector is mated or unmated, it risks contamination. Therefore, cleaning the connector end-face before every connection is not just recommended—it is mandatory for professional installers. To make this process quick, effective, and reliable, specialized tools are necessary. The Fiber Optic Cassette Cleaner is an essential tool in any technician’s kit. It uses a lint-free cleaning tape to effectively remove dust, oil, and other debris without scratching the delicate end-face, ensuring a pristine connection every single time.

Future-Proofing Your Network: Emerging Trends in Fiber Optic Adaptors

The technology of fiber optics is constantly evolving, driven by the insatiable demand for more bandwidth. The components that build these networks, including fiber optic adaptors, are also advancing to meet these new challenges. Staying aware of these trends is key to building a network that will not only serve today’s needs but can also scale for the demands of tomorrow.

Increased Density and Miniaturization

The trend of miniaturization continues. As data center real estate becomes more valuable, the pressure to fit more connections into a smaller footprint intensifies. While LC connectors are a huge improvement over SC, even smaller form factors are emerging. Connectors like the CS, SN, and MDC are designed to further increase the density on faceplates, allowing more fibers to be connected in the same amount of space. The adaptors for these new formats are being developed to support this next generation of high-density hardware, enabling future network speeds of 400G, 800G, and beyond.

Expanded Beam Technology

For harsh environments or applications requiring frequent mating and de-mating, expanded beam technology offers a revolutionary alternative. Instead of making physical contact, a lens within the connector collimates the light into a wider, parallel beam. This beam crosses a small air gap to a second lens in the other connector, which refocuses the light into the receiving fiber. Because there is no physical contact, this technology is incredibly resistant to dust and debris and offers extreme durability. The adaptors for these systems are more complex, but their reliability in dirty or high-vibration environments is unmatched.

Adherence to Evolving Global Standards

As technology advances, so do the standards that govern it. Global bodies like the International Electrotechnical Commission (IEC) work to ensure that components from different manufacturers are interoperable and meet strict performance criteria. Future adaptors will need to comply with new standards for higher data rates, different fiber types, and more stringent loss budgets. Choosing a supplier like EPCOM, which is committed to staying at the forefront of these standards, is the best way to ensure your network remains compatible and performant well into the future.

Conclusion: Your Trusted Partner for Superior Connectivity

Fiber optic adaptors are far more than simple plastic housings; they are precision-engineered components that lie at the very heart of digital communication. From their role in meticulously aligning fiber cores to ensuring the integrity of light signals over vast distances, their importance cannot be overstated. As we have explored, the choice of adaptor—from its type (LC, SC, MPO) to its core specifications like sleeve material and loss ratings—has a direct and significant impact on network reliability, performance, and scalability.

Making the right choice requires a deep understanding of both the technology and the application. It means recognizing that a high-performance network is an integrated system where adaptors, patch cords, and maintenance practices all work in concert. EPCOM stands as your expert partner in this field, dedicated to providing not just components, but complete, high-quality solutions built on a foundation of precision engineering and a commitment to evolving standards. By choosing EPCOM, you are investing in the long-term health and performance of your most critical network infrastructure.

Ready to build a faster, more reliable network? Explore EPCOM’s complete range of premium Fiber Optic Adaptors and connectivity solutions today.