Parallel Groove Connectors: The Complete Guide 2025

Parallel Groove Connectors are a cornerstone of modern electrical power transmission and distribution systems. As the demand for reliable and uninterrupted electricity grows, the importance of high-quality connection components cannot be overstated. These seemingly simple devices play a critical role in ensuring the integrity and efficiency of electrical grids worldwide. At EPCOM, we understand that a secure connection is the foundation of a stable power supply. This comprehensive guide will delve deep into the world of parallel groove connectors, exploring everything from their fundamental principles and diverse types to installation best practices and their essential role in the broader electrical ecosystem. Whether you are an engineer, a technician, or a project manager, this article will provide you with the expert knowledge needed to make informed decisions about your electrical connection solutions.

Throughout this guide, we will cover the technical specifications, material science, and practical applications that make these components indispensable. Furthermore, we will highlight how selecting the right connector, alongside proper tools and associated hardware, contributes to the longevity and safety of any electrical installation. Let’s begin our journey into mastering the science and application of these vital electrical components.

What Exactly Are Parallel Groove Connectors?

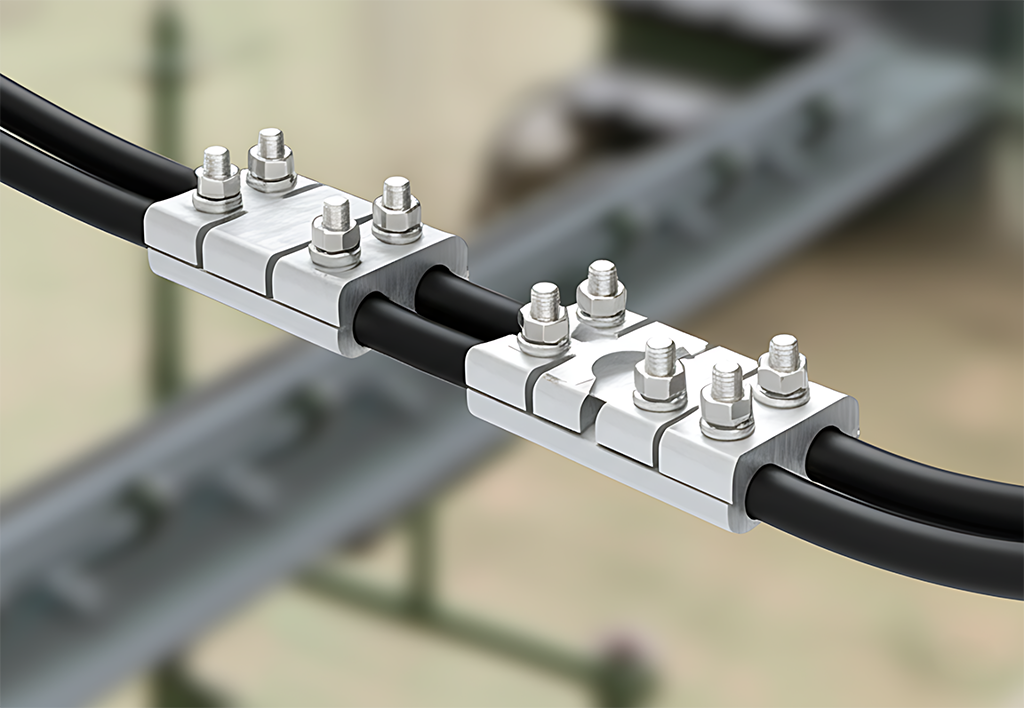

In essence, a Parallel Groove Connector, often abbreviated as a PG clamp, is a mechanical connector used to create a secure electrical connection between two parallel conductors without the need for cutting or splicing them. Imagine two parallel roads needing a bridge; the PG clamp acts as that bridge, allowing electrical current to flow from one conductor to the other seamlessly. These connectors are typically made of a high-strength, corrosion-resistant aluminum alloy or copper, and sometimes a combination of both in bimetallic versions.

The design is elegantly simple yet highly effective. A standard PG clamp consists of two main parts: an upper body and a lower body. Each body has one or more grooves designed to hold the conductors. High-tensile steel or stainless steel bolts and nuts are used to clamp these two bodies together, exerting significant pressure on the conductors nestled within the grooves. This pressure serves two primary functions: it establishes a firm mechanical grip, preventing the conductors from slipping, and it creates a low-resistance electrical pathway for the current.

The Core Function of Parallel Groove Connectors

The primary function of any parallel groove connector is to ensure a reliable, long-lasting, and low-resistance electrical tap connection. The term “tap” or “tee” connection refers to branching a smaller conductor off a main, continuous conductor. This is a common requirement in power distribution networks where electricity needs to be routed from a main power line to smaller lines feeding residential areas, commercial buildings, or industrial facilities.

The mechanical principle is based on creating and maintaining sufficient contact pressure. When the bolts are tightened to a specific torque value, the connector bodies deform slightly, forcing the conductors to conform to the shape of the grooves. This action breaks through the thin layer of non-conductive oxide that naturally forms on the surface of conductors (especially aluminum). Moreover, a high-quality connector often includes a specially formulated oxide-inhibiting compound pre-applied in the grooves. This grease-like substance prevents moisture and air from re-oxidizing the contact surfaces, thereby ensuring a stable, low-resistance connection for decades. Consequently, the reliability of the entire grid depends heavily on the performance of thousands of these individual connectors.

Exploring the Types of Parallel Groove Connectors

Parallel groove connectors are not a one-size-fits-all solution. They are manufactured in various materials and designs to suit different conductor types, environmental conditions, and specific applications. Understanding these variations is crucial for selecting the appropriate component for your project. EPCOM offers a range of connectors designed to meet these diverse needs.

1. Aluminum Parallel Groove Connectors

These are the most common type, primarily used for connecting Aluminum to Aluminum conductors (AAC, AAAC, or ACSR). They are made from high-strength, corrosion-resistant aluminum alloys. Since most overhead transmission and distribution lines use aluminum-based conductors due to their excellent conductivity-to-weight ratio, aluminum PG clamps are the default choice for tapping these lines. Their lightweight nature makes them easy for linemen to handle and install.

2. Copper Parallel Groove Connectors

Used for connecting Copper to Copper conductors, these clamps are made from high-conductivity copper alloys. Copper conductors are typically found in grounding applications, substations, and industrial facilities where high conductivity and resistance to corrosion are paramount. Using a copper clamp for copper wires prevents issues related to mismatched materials.

3. Bimetallic Parallel Groove Connectors (AL/CU)

This is arguably the most technically sophisticated type of PG clamp. Bimetallic connectors are essential for joining an aluminum conductor to a copper conductor. Directly connecting aluminum and copper in the presence of an electrolyte (like moisture) creates a galvanic cell, leading to rapid galvanic corrosion of the aluminum conductor. To prevent this, bimetallic PG clamps are designed with one aluminum alloy body and one copper alloy body, or more commonly, an aluminum body with a copper insert fused or friction-welded into one of the grooves. This design ensures that aluminum only touches aluminum and copper only touches copper, isolating the two dissimilar metals and preventing corrosive failure. These are critical for tapping from aluminum overhead lines to copper service drops for buildings.

Critical Applications for Parallel Groove Connectors

The versatility and reliability of PG clamps make them suitable for a wide array of applications in the electrical industry. Their primary use is in overhead electrical line construction and maintenance.

- Power Distribution Networks: Tapping from main distribution lines to feed transformers that step down the voltage for residential and commercial use.

- Transmission Lines: While less common for main conductor connections, they are used for non-tension jumper loops at suspension towers and for connecting grounding wires.

- Substations: Making non-tension connections between busbars, equipment, and outgoing feeders.

- Street Lighting: Connecting the power feed for streetlights to the main overhead distribution lines.

- Railway Electrification: Used in overhead lines (catenary systems) that power electric trains.

- Industrial Plants: For tapping power from main busways to individual machinery or sections of a plant.

How to Select the Right Parallel Groove Connector

Choosing the correct parallel groove connector is not just a matter of picking one that fits. Several factors must be considered to ensure a safe, reliable, and long-lasting connection. An incorrect choice can lead to overheating, connection failure, and power outages.

Here are the key criteria for selection:

- Conductor Material: As discussed, match the connector material to the conductor material. Use Aluminum for Al-Al, Copper for Cu-Cu, and Bimetallic for Al-Cu connections.

- Conductor Size Range: Every PG clamp is designed to accommodate a specific range of conductor diameters. Ensure that both your main conductor and your tap conductor sizes fall within the specified range for the chosen clamp. Using an oversized or undersized clamp will result in a poor connection.

- Environmental Conditions: For highly corrosive environments, such as coastal areas with salt spray or industrial zones with chemical fumes, select connectors made from more resilient alloys or with special protective coatings.

- Voltage Level: Ensure the connector is rated for the voltage of the system. While most PG clamps are suitable for low and medium voltage, high-voltage applications may require specially designed connectors.

- Compliance with Standards: Always choose connectors that comply with international standards like IEC 61238-1 or IEEE standards. This ensures they have passed rigorous testing for mechanical strength and electrical performance. EPCOM is committed to providing products that meet or exceed these stringent requirements.

To simplify the selection process, here is a quick reference table:

| Connector Type | Main Conductor | Tap Conductor | Primary Application |

|---|---|---|---|

| Aluminum (Al) PG Clamp | Aluminum (AAC, AAAC, ACSR) | Aluminum (AAC, AAAC, ACSR) | Overhead distribution lines |

| Copper (Cu) PG Clamp | Copper | Copper | Substation grounding, industrial wiring |

| Bimetallic (Al/Cu) PG Clamp | Aluminum | Copper | Connecting aluminum main lines to copper service drops |

Installation Guide for Parallel Groove Connectors

A high-quality connector can only perform as well as its installation. Improper installation is a leading cause of connector failure. Following a meticulous procedure is essential for safety and reliability.

- Prepare the Conductors: Before installing the clamp, the surfaces of both conductors must be thoroughly cleaned. Use a wire brush to vigorously brush the contact areas. This removes the surface oxide layer and any dirt or grease. For ACSR conductors, be careful not to damage the underlying steel core.

- Apply Oxide Inhibitor: Immediately after brushing, apply a generous layer of oxide-inhibiting compound to the cleaned conductor surfaces. This is a critical step. Even if the connector comes pre-filled, adding a fresh layer to the conductors provides maximum protection against re-oxidation.

- Position the Connector: Open the PG clamp by loosening the bolts. Place the conductors into the appropriate grooves. Ensure the main (continuous) conductor is typically placed in the lower groove for stability.

- Tighten the Bolts: Hand-tighten the bolts initially to secure the connector in place. Then, using a calibrated torque wrench, tighten the bolts alternately and evenly. This ensures uniform pressure is applied across the connector. Continue tightening until the manufacturer’s recommended torque value is reached. Over-tightening can damage the conductor strands and the connector itself, while under-tightening will result in a high-resistance, hot-running connection.

- Final Inspection: After tightening, visually inspect the connection. Ensure the connector is sitting straight and the conductors are properly seated in the grooves. Wipe off any excess inhibitor compound from the exterior of the connector.

The Importance of Proper Tools and Related Electrical Components

The reliability of an electrical network is a system-level property. While parallel groove connectors are vital, their performance is intrinsically linked to the quality of the conductors they connect and the tools used for installation. At EPCOM, we advocate for a holistic approach to building robust electrical infrastructure.

For connections that require termination or splicing under tension, compression fittings are often used. These require specialized tools to ensure a proper cold weld is formed. For these demanding jobs, having a powerful and reliable tool is non-negotiable. The EPCOM YQK Cable Crimping Pliers are an example of a high-quality hydraulic tool designed for such tasks, providing the necessary force to create dependable crimped connections on lugs and splices.

Furthermore, not all connections involve bare, uninsulated conductors. In many modern distribution systems, especially in urban areas, insulated cables are used to enhance safety and reliability. When tapping from these insulated cables, a different technology is required. Insulation Piercing Connectors (IPCs) are designed to make a connection without stripping the cable’s insulation. The JBC Insulation Piercing Connector from EPCOM is an excellent solution for these applications, featuring shear-head bolts that guarantee perfect tightening torque while its sharp teeth penetrate the insulation to make a secure, waterproof connection.

Of course, the connectors and tools are only as good as the cables themselves. The choice of conductor is the first and most fundamental decision in any electrical project. Aerial Bundled Cables (ABC) have become a preferred choice for overhead distribution networks due to their higher safety, reliability, and lower maintenance requirements compared to traditional bare conductor systems. The EPCOM ABC Cable is manufactured to the highest standards, providing a durable and efficient solution for power distribution. When used in conjunction with our range of connectors and tools, it forms a complete, reliable system.

Maintenance and Safety Considerations for Parallel Groove Connectors

While a properly installed, high-quality parallel groove connector is designed to be maintenance-free for many years, periodic inspections are a good practice, especially in critical locations or harsh environments. The most effective inspection method is thermography. Using an infrared camera, maintenance crews can scan power lines to detect “hot spots.” A connector that is running significantly hotter than the conductor itself is an indication of high resistance and an impending failure. This allows for proactive replacement before a power outage occurs.

Safety during installation and maintenance is paramount. All work on overhead lines should be performed by qualified and authorized personnel using appropriate personal protective equipment (PPE). The line should be de-energized and properly grounded before any work begins, following established lockout/tagout procedures.

EPCOM’s Commitment to Quality Electrical Connections

At EPCOM, our mission extends beyond simply supplying parts. We are dedicated to providing comprehensive solutions that enhance the reliability and safety of electrical infrastructure. Our range of parallel groove connectors, from standard aluminum models to specialized bimetallic clamps, is manufactured using premium raw materials and state-of-the-art processes. Every product undergoes rigorous quality control to ensure it meets the mechanical and electrical demands of real-world applications.

We believe that a superior product is only part of the equation. We support our clients with expert technical advice to ensure they select the right components and use them correctly. By offering a synergistic portfolio of cables, connectors, and tools, EPCOM positions itself as a trusted partner in building the resilient power grids of tomorrow.

Frequently Asked Questions About Parallel Groove Connectors

Q1: Why can’t I use an aluminum PG clamp to connect a copper wire?

You must not use a standard aluminum clamp for a copper wire due to galvanic corrosion. When two dissimilar metals like aluminum and copper are in contact in the presence of moisture, an electrochemical reaction occurs that rapidly corrodes the aluminum. This leads to a loose, high-resistance connection that will eventually fail. You must use a bimetallic (Al/Cu) connector specifically designed for this purpose.

Q2: What happens if I don’t use a torque wrench to install a parallel groove connector?

Failing to use a torque wrench is a common cause of connection failure. If you under-tighten the bolts, the contact pressure will be insufficient, leading to high resistance, overheating, and eventual burnout. If you over-tighten the bolts, you can damage the conductor strands, stretch the bolt beyond its elastic limit, or even crack the connector body, all of which compromise the connection’s integrity.

Q3: Is the oxide-inhibiting compound really necessary?

Yes, it is absolutely essential, especially for aluminum conductors. Although you wire-brush the conductor, a new, thin layer of insulating aluminum oxide forms almost instantly upon exposure to air. The inhibitor compound penetrates this layer and seals the connection from air and moisture, preventing future oxidation and ensuring a stable, low-resistance path for the current over the long term.

Q4: Can I reuse a parallel groove connector?

It is strongly recommended not to reuse parallel groove connectors. The bolts are often torque-yield bolts, meaning they are designed to stretch permanently upon proper tightening. Reusing them may not provide the required clamping force. Furthermore, the connector body itself deforms to grip the conductors, and it may not provide the same quality of connection on a new installation. Given their low cost relative to the cost of a failure, it is always best practice to use a new connector for every new connection.

Conclusion: The Foundation of a Reliable Grid

Parallel Groove Connectors, though small components in a vast network, are fundamental to the reliable distribution of electrical power. Their proper selection, installation, and integration with other high-quality components form the bedrock of a safe and efficient electrical grid. From understanding the critical difference between aluminum, copper, and bimetallic types to appreciating the meticulous installation process, every detail matters.

EPCOM is your dedicated partner in this endeavor. We provide not only the superior components you need but also the expertise to support your projects. By choosing EPCOM’s range of parallel groove connectors and related electrical products, you are investing in durability, safety, and long-term performance. Contact us today to learn how we can help you build stronger connections for a brighter future.