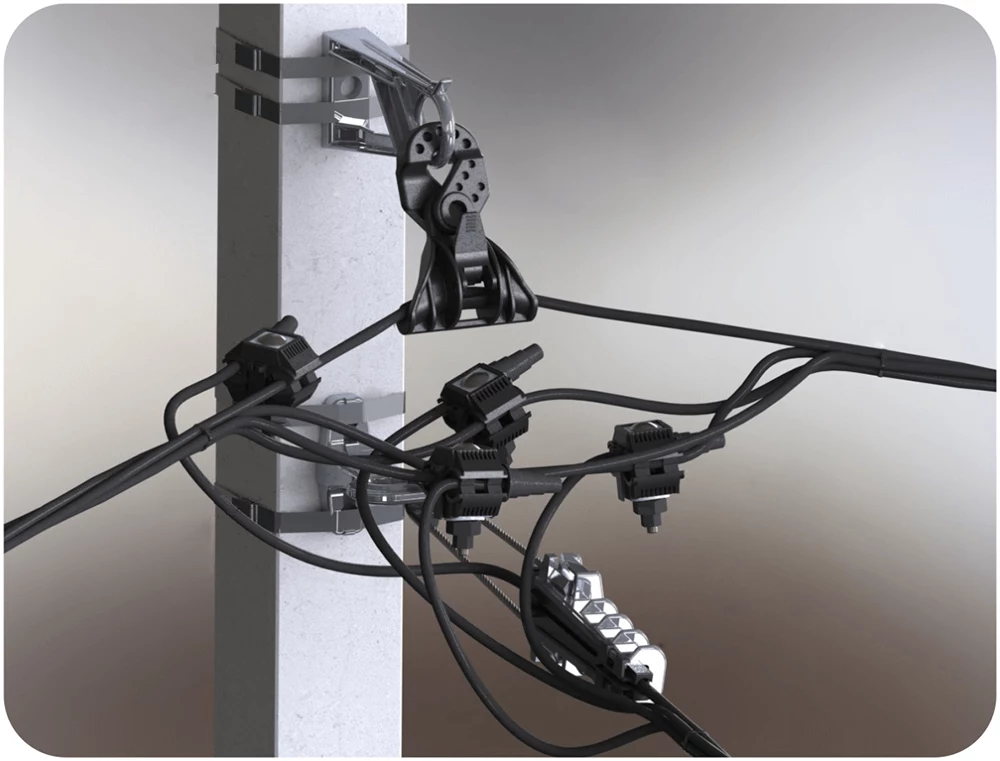

TTD Insulation Piercing Connector

The TTD Insulation Piercing Connector is a reliable, safe, and easy-to-use connector for connecting insulated cables without stripping the insulation. It is ideal for use in a variety of applications, including power distribution, telecommunications, and signal transmission.

- “No-strip” design for faster installation.

- Versatile for aluminum and copper conductors.

- Fully insulated and waterproof.

- Shear head bolt ensures correct tightening.

- UV resistant and withstands harsh temperatures.

- Compact design for confined spaces.

Description

The TTD Insulation Piercing Connector series from EPCOM offers a revolutionary solution for establishing secure and reliable electrical connections without the need to strip conductor insulation. This innovative technology simplifies installation processes, saves valuable time, and enhances the overall safety and longevity of electrical joints in a variety of applications. Designed for both aluminum and copper conductors, these connectors are indispensable for overhead and underground distribution networks, as well as for street lighting and building electrical systems. Their robust construction ensures optimal performance even in harsh environmental conditions, making them a preferred choice for utility companies and electrical contractors worldwide.

Understanding the TTD Insulation Piercing Connector

An Insulation Piercing Connector (IPC) is a type of electrical connector that utilizes specially designed blades or teeth to penetrate the conductor’s insulation and make a direct, solid contact with the metallic core. The TTD Insulation Piercing Connector by EPCOM is engineered with precision to ensure this process is seamless and effective. The connector body is typically made from high-strength, weather-resistant insulating material, providing excellent mechanical protection and electrical insulation. The piercing elements are crafted from conductive alloys, often tinned copper or aluminum, to ensure low contact resistance and prevent corrosion. A key feature is the shear head bolt, which breaks off at a predetermined torque, guaranteeing correct tightening force and a reliable connection every time without requiring specialized torque wrenches. This significantly reduces the risk of improper installation, a common cause of connection failure.

Key Features of EPCOM’s TTD Insulation Piercing Connector

EPCOM’s TTD series connectors come packed with features that set them apart. Firstly, their versatility allows for connections between insulated aluminum conductors (IAC) and insulated copper conductors. Secondly, the “no-strip” design means faster installation and reduced chances of conductor damage that can occur during manual stripping. Moreover, these connectors are fully insulated and waterproof, often featuring an end cap to seal the cut end of the branch cable, preventing moisture ingress. The electrical contact is made by sharp teeth that pierce the insulation of both main and tap conductors simultaneously when the bolt is tightened. This creates a stable, low-resistance connection. The bolts are often of the shear-head type, ensuring that the correct torque is applied, which is crucial for long-term performance. This design is particularly advantageous for live-line working in some applications, although local safety regulations must always be paramount.

Furthermore, the materials used in our TTD Insulation Piercing Connectors are UV resistant and can withstand a wide range of temperatures and environmental pollutants. This durability translates into a longer service life and reduced maintenance costs for electrical infrastructure. The compact design also allows for installation in confined spaces, providing greater flexibility in network planning and execution.

Diverse Applications of the TTD Connector

The TTD Insulation Piercing Connector is exceptionally versatile, finding its application across numerous electrical distribution scenarios. In overhead low-voltage distribution networks, these connectors are used for making tap-offs from main lines to service individual customers or to branch off secondary lines. Their ease of installation makes them ideal for both new constructions and for upgrading existing networks. Similarly, in underground distribution systems, where environmental sealing is even more critical, the waterproof design of TTD connectors ensures reliable, long-lasting connections.

Street lighting systems also benefit significantly from the use of TTD connectors. They allow for quick and secure connections to lighting fixtures from the main supply cables, simplifying maintenance and replacement tasks. In building electrical systems, particularly for larger commercial or industrial installations, these connectors can be used for distributing power to various sections or heavy-duty equipment. The ability to connect dissimilar metals (e.g., aluminum main to copper tap) without concerns of galvanic corrosion (when properly designed and selected) is another significant advantage. The reliability and safety offered by the TTD Insulation Piercing Connector make it an essential component in modern power distribution systems.

Technical Specifications: TTD 201F Insulation Piercing Connector

The TTD 201F model, as an example from our TTD series, embodies the quality and reliability EPCOM is known for. Below are its key specifications:

| Parameter | Value |

|---|---|

| Model | TTD 201F |

| Main Conductor Range (Al/Cu) | 35-95 mm² |

| Tap Conductor Range (Al/Cu) | 25-95 mm² (as indicated by 25-95°) |

| Nominal Current | Refer to specific conductor ampacity |

| Tightening Torque | 14 Nm (Shear head bolt H13) |

| Body Material | UV and Weather Resistant Thermoplastic |

| Contact Teeth Material | Tinned Copper Alloy / Aluminum Alloy |

| Waterproof Standard | IP67 (when correctly installed with end caps) |

| Standard Compliance | IEC 61238-1, NFC 33-020 or equivalent |

| Marking | TNB (Manufacturer/Series Indicator) |

Note: Specifications can vary slightly between different models within the TTD series. Always refer to the specific product datasheet for precise information before installation.

Installation Guidelines and Safety for TTD Connector

Proper installation is paramount for the TTD Insulation Piercing Connector to function correctly and safely. Although designed for ease of use, certain guidelines must be followed. Always ensure that the conductor sizes are within the specified range for the connector model being used. The conductors should be clean and free from any excessive surface contaminants, though the piercing teeth are designed to penetrate standard insulation. When tightening the shear head bolt, use a standard socket wrench. The head will shear off once the correct torque is achieved, preventing over or under-tightening.

Safety is a non-negotiable aspect of any electrical work. Ensure the line is de-energized before commencing installation, unless specific live-line procedures approved by your utility and local regulations are being followed by trained personnel. Wear appropriate Personal Protective Equipment (PPE), including insulated gloves and eye protection. After installation, visually inspect the connection to ensure the connector body is intact and the conductors are securely held. For applications requiring waterproofing, ensure any supplied end caps or grease are correctly applied. Regular inspection as part of a network maintenance schedule can help identify any potential issues early, although TTD connectors are designed for a long, maintenance-free life.

Why Choose EPCOM for Your TTD Insulation Piercing Connector Needs?

EPCOM is committed to providing high-quality, reliable, and innovative solutions for the electrical industry. Our TTD Insulation Piercing Connector range is a testament to this commitment. We employ stringent quality control measures throughout the manufacturing process, from raw material sourcing to final product testing. This ensures that every connector leaving our facility meets the highest standards of performance and safety. Our connectors are designed based on extensive research and development, incorporating feedback from field engineers and aligning with international standards like IEC (International Electrotechnical Commission).

Furthermore, EPCOM offers comprehensive technical support and customer service. We understand that each project has unique requirements, and our team is ready to assist you in selecting the most suitable TTD Insulation Piercing Connector for your specific application. Our logistical network ensures timely delivery to meet your project schedules. By choosing EPCOM, you are partnering with a company that values quality, innovation, and customer satisfaction above all else. We strive to build long-term relationships with our clients by consistently delivering products that enhance efficiency and reliability in electrical systems.

Related Products and Tools from EPCOM

To complement your work with TTD connectors and other electrical installations, EPCOM offers a wide range of related products and tools. Enhance your toolkit and project efficiency with these quality solutions:

- JBC Insulation Piercing Connector: For applications requiring different specifications or connection types, explore our JBC series, another reliable option for insulated conductor connections.

- YQK Cable Crimping Pliers: Essential for creating secure crimped connections on various cable lugs and connectors. Our YQK series offers durability and precision for professional results.

- Wire Stripper Cutter: While TTD connectors don’t require stripping, many other electrical tasks do. Our wire stripper cutters are designed for efficiency and safety in preparing cable ends.

At EPCOM, we aim to be your one-stop solution for high-quality electrical components and tools. Explore our website for our full product catalog and discover how we can support your next project.

In conclusion, the TTD Insulation Piercing Connector from EPCOM provides a superior method for making electrical connections on insulated conductors. Its innovative design, robust construction, and ease of installation contribute to safer, more reliable, and cost-effective electrical networks. Whether for overhead, underground, or specialized applications, these connectors deliver performance you can trust. Contact EPCOM today to learn more about our TTD series and how they can benefit your electrical infrastructure projects.