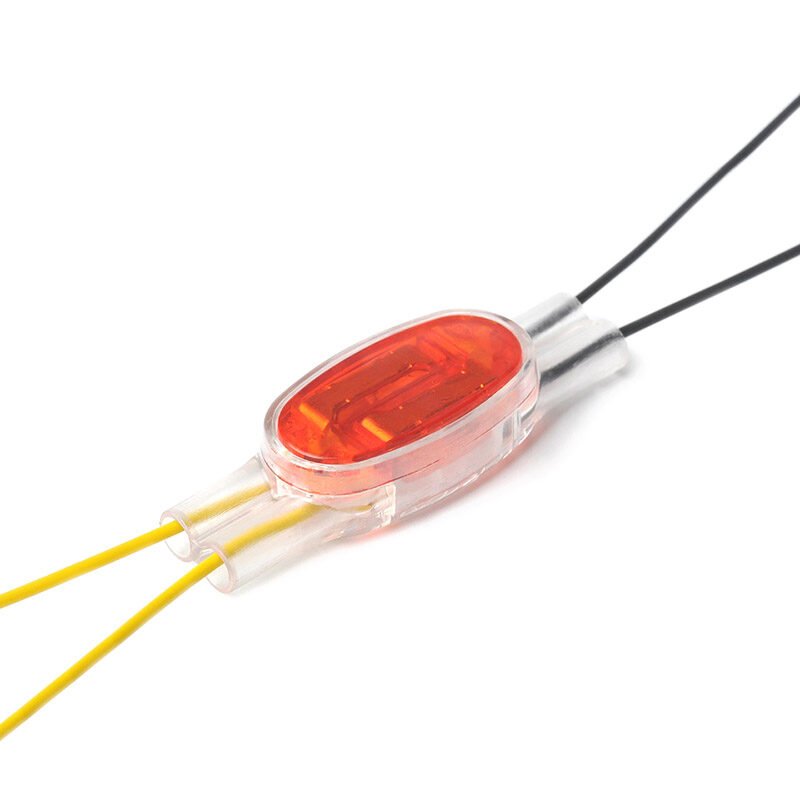

U1R Inline Connector for Telecom Solutions

U1R Inline Connectors are a safe and simple way to make a secure connection. These full-pair, sealed, moisture resistant connectors are designed to accommodate a wide range of wire ranges. They are ideal for use in a variety of applications, including splicing, voice, data, and premise wiring.

- Moisture-resistant splices.

- No wire stripping needed due to IDC technology.

- For 19-24 AWG solid copper conductors.

- Gel-filled for moisture protection.

- Red housing for identification.

Description

The U1R Inline Connector from EPCOM offers a robust and dependable solution for creating secure, moisture-resistant splices in telecommunication and signal wiring. Engineered for efficiency and longevity, this connector utilizes Insulation Displacement Connection (IDC) technology, which simplifies the splicing process by eliminating the need for wire stripping. This significantly reduces installation time and enhances the overall integrity of the connection, making it an ideal choice for professionals in the field.

Designed primarily for solid copper conductors, typically within the 19-24 AWG range, the EPCOM U1R connector ensures a gas-tight and corrosion-resistant seal. Its internal gel filling provides an exceptional barrier against moisture, humidity, and other environmental contaminants. This feature is particularly critical for outdoor applications or in environments where connections are exposed to harsh conditions, safeguarding signal integrity and preventing degradation over time. The distinct red housing of the U1R series is a common identifier for this wire gauge compatibility.

Key Features and Design of the U1R Inline Connector

EPCOM’s U1R Inline Connector is meticulously designed to meet the stringent demands of modern telecommunication networks. Its construction and material selection are focused on providing a durable and easy-to-use solution for splicing low-voltage copper conductors.

Superior Sealing and Protection

At the core of the U1R connector’s reliability is its factory-installed sealant. This gel filling comprehensively encases the conductors once crimped, providing a formidable defense against moisture ingress. The importance of moisture resistance in electrical connectors cannot be overstated, especially in outside plant (OSP) applications where temperature fluctuations and precipitation are common. This protection helps to prevent corrosion, which is a leading cause of signal loss and connection failure in telecommunication circuits. The robust polycarbonate housing further enhances its durability, offering resistance to impact and UV exposure.

Efficient IDC Mechanism

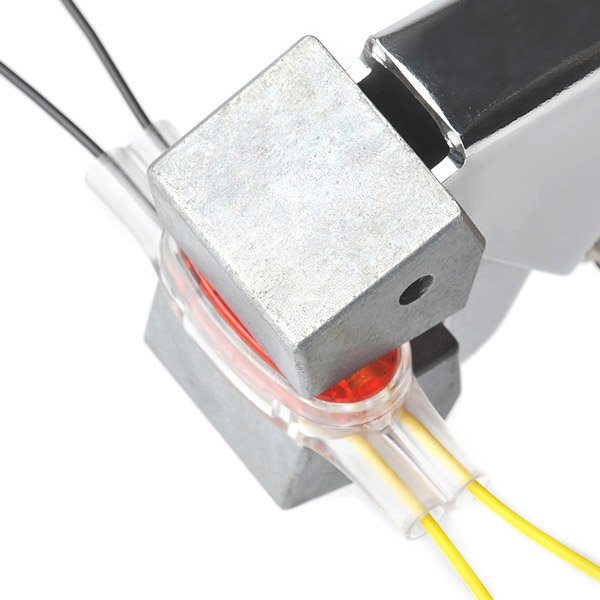

The Insulation Displacement Connection (IDC) technology integrated into the U1R connector streamlines the wire splicing process. Each wire slot features a sharp, U-shaped contact element. When a wire is inserted and the connector is crimped using a standard crimping tool (such as the E-9BM or equivalent), these contacts cleanly pierce the insulation and make a secure, stable connection with the copper conductor. This method not only saves time by eliminating manual wire stripping but also ensures a consistent and reliable electrical contact. The precision-engineered contacts maintain a high normal force on the conductors, contributing to a low-resistance and long-lasting connection.

Ease of Installation

Installation of the U1R connector is straightforward. Wires are simply inserted into the designated ports without prior stripping. A single crimp action with an appropriate tool completes the splice, creating both an electrical connection and sealing the wires. This ease of use reduces installation time and minimizes the potential for human error, making it a preferred choice for both experienced technicians and those new to IDC technology. The compact design of the connector also allows for use in tight spaces and high-density splice enclosures.

Applications for the U1R Inline Connector

The versatility and robust design of the U1R Inline Connector make it suitable for a wide array of applications across various industries, primarily focusing on telecommunications and low-voltage electrical systems.

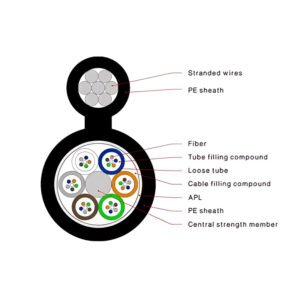

- Telecommunications: Ideal for splicing drop wires, repairing damaged lines, and extending network reach in both traditional copper and hybrid networks. Its moisture resistance ensures reliable performance in pedestals, aerial applications, and direct-buried scenarios.

- Signal and Control Wiring: Used in security systems, HVAC controls, and other low-voltage signaling circuits where reliable connections are paramount.

- Data Networks: Suitable for certain types of data cabling where small gauge copper conductors are used and environmental protection is necessary.

- Rural Utilities: Often meets specifications for RUS (Rural Utilities Service) listed applications, ensuring dependable connections in rural telecommunication infrastructures.

The ability to quickly and reliably join wires without stripping insulation makes the U1R connector a time-saving asset in large-scale deployments and routine maintenance tasks. When considering alternatives, EPCOM also offers other specialized connectors such as the U1B Inline Connector for larger wire gauges (typically 16-19 AWG) and the versatile 101SG Inline Connector for different application needs.

Technical Specifications of the EPCOM U1R Connector

Below is a detailed summary of the technical specifications for the EPCOM U1R Inline Connector. These parameters highlight its capabilities and suitability for various applications.

| Parameter | Specification |

|---|---|

| Product Name | EPCOM U1R Inline Connector |

| Connection Type | Inline, Butt Splice (IDC) |

| Number of Wires | Up to 2 copper conductors (typically one pair) |

| Wire Gauge Compatibility (Solid Copper) | 19-24 AWG (0.5-0.9mm² diameter) |

| Maximum Insulation Outer Diameter | Approx. 0.125 inches (3.18 mm) |

| Housing Material | Polycarbonate |

| Color | Red body |

| Sealant | Moisture-resistant gel filled |

| Operating Temperature Range | -40°C to +60°C (-40°F to +140°F) |

| Voltage Rating | Typically suitable for low voltage applications (e.g., up to 100V, application dependent) |

| Recommended Crimping Tool | Standard IDC crimping tool (e.g., E-9BM type) |

| Compliance (Typical for type) | May meet RUS specifications for telecommunication connectors (verify specific EPCOM certifications) |

Installation Guidelines for the U1R Inline Connector

To ensure optimal performance and longevity of connections made with the U1R Inline Connector, follow these best practices:

- Confirm Wire Compatibility: Verify that the wire gauge (19-24 AWG solid copper) and insulation diameter are within the connector’s specified range. Using incorrect wire sizes can lead to poor connections or damage to the connector.

- Do Not Pre-Strip Wires: The IDC mechanism is designed to work with insulated wires. Stripping the wires beforehand is unnecessary and can compromise the connection quality.

- Proper Wire Insertion: Insert unstripped wires fully into the designated ports until they hit the end stop. Ensure wires are inserted straight.

- Use the Correct Crimping Tool: Employ a crimping tool specifically designed for IDC butt connectors, such as the E-9BM or an EPCOM-recommended equivalent. Apply firm, even pressure until the crimping cycle is complete. This action drives the U-contacts through the insulation and secures the conductors.

- Inspect the Connection: After crimping, visually inspect the connector to ensure the cap is fully seated and the wires are securely held. The gel sealant should be visible, indicating a proper seal.

- Avoid Over-Crimping: While firm pressure is needed, excessive force or using the wrong tool can damage the connector housing or the internal contacts.

- Environmental Considerations: While gel-filled for moisture resistance, ensure that for extremely harsh environments or direct burial, appropriate secondary protection (e.g., splice enclosures) is considered for the overall cable integrity.

Why Choose EPCOM’s U1R Solution?

EPCOM is committed to providing high-quality connectivity solutions that enhance network reliability and streamline installation processes. The U1R Inline Connector embodies this commitment by offering a dependable, easy-to-use, and environmentally sealed splicing method. Its proven IDC technology, combined with robust construction, ensures long-term performance in demanding telecommunication and low-voltage applications.

By choosing EPCOM, you benefit from products designed with the professional installer in mind, backed by expertise in telecommunications components. For applications requiring different specifications, such as bridging connections, consider the EPCOM UB2A Bridging Connector, which offers similar IDC benefits for tap and bridge splicing.

Ultimately, the U1R connector from EPCOM represents a cost-effective and high-performance choice for ensuring the integrity of critical connections, reducing maintenance needs, and supporting the longevity of your network infrastructure. Its features are tailored to provide a secure splice that withstands environmental challenges, making it a trusted component for professionals worldwide.